All about sheets of PVL 406

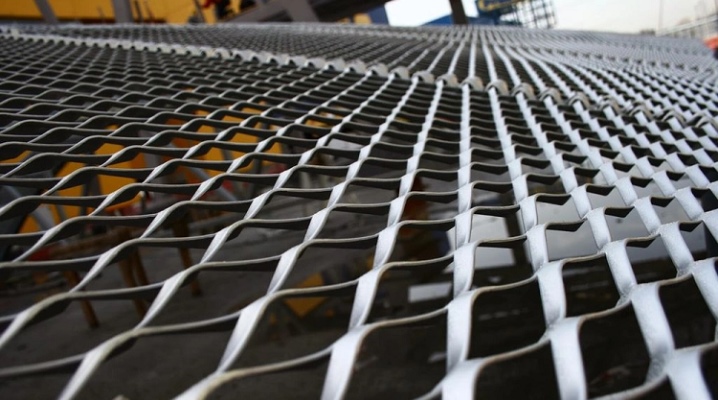

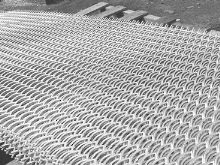

Expanded metal sheet is, in fact, a fine-structured lattice that resembles a coarse sieve. Its production, despite its apparent simplicity, has a number of features that determine its use.

Peculiarities

406 PVL sheet, for example, is considered one of the dimensional options. The dimensions are set not only for the entire fragment of the sheet material as a whole, but also for each of the contour holes, whose outlines resemble the scales of the outer protective cover of a fish. Despite the fineness of the cells made, resembling the structure of an openwork mesh, sheet products of size 406 are characterized by high strength characteristics, acceptable rigidity, low weight, as well as the transmission of liquids, light, heat and air flows. It serves as a kind of coarse filter for liquid purification - for this purpose it can be used in wastewater treatment plants with staged wastewater treatment.

The decoding of the marking may include the following designations (markers): step "C", feed "B", draw "A". The appearance of the grid has sufficient attractiveness, so it can be used for design decoration in technical and even premises of a mass gathering of people. Despite its attractiveness, sheet 406 has sharp, tiny edges that force people, for example, not to lean against a wall. The economically justified cost of these products allows you to create designs with any appearance and structure, while the metal consumption is reduced by up to 5 times compared to conventional sheets made of solid material. One of the advantages of PVL is the independence of flexibility from the rigidity of the structure.

The cells are made in such a form that the expanded metal blanks do not slip.

Nuances of production

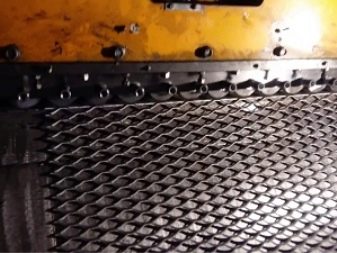

The expanded metal sheet is produced according to the conditions of GOST 8706-1978. Grooved and extruded edges are created at the same time. Metal sheets pass through shafts, leveling the workpieces, preventing them from bending randomly and in all directions; deformation when folding the sheet into rolls is also excluded. To avoid these damages, the workpieces of expanded metal are passed through the machine on which the CNC unit operates. In addition to galvanized steel, PVL is made of aluminum, stainless steel, any low-carbon steel.

The weldability of the sheet is not particularly limited, however, special methods based on multi-spot welding are used to produce framed workpieces. This type of welding involves the simultaneous attachment of a large section of any of the edges along one line. How many cells go to either side of the cut of the expanded metal mesh, so many points of attachment are formed. However, the gap-riveting method of fixing the mesh to the frame is more often used: the edges of the frame, welded from steel strips or cut from another, thicker solid sheet of steel, are bent into a technological groove, into which a suitable size PVL fragment is inserted from all four sides.

Then, using a special edge (frame) press, the mesh is clamped in this "tack", after which the resulting product is sent for further processing, for example, anodizing. This method can be useful, for example, for installing framed expanded metal in the gap of the window of an industrial building. However, for example, in the market of household metal-plastic windows, this mesh has not gained popularity.And the point is not so much the high cost compared to similar polymer nets, but rather the large size of the edge-exhaust holes through which mosquitoes, for example, can get their way.

All the same steel alloys St3Kp and St3GSp can be used as a raw material for the production of expanded metal. To get rid of rusting, the PVL mesh is painted with rust enamel, using, for example, its spraying from an aerosol can.

Compliance with the rules for installation and final processing will provide products with expanded metal a long - for decades - service life.

The last, final stage of the production of expanded metal is as follows. The sheet being checked is selected from three identical blanks, then its suitability is assessed according to compliance with the standards that are prescribed in the program that ensures the operability of the CNC machine. It is not necessary to recheck all items one at a time: only some of the sheets from the final batch need to be evaluated.

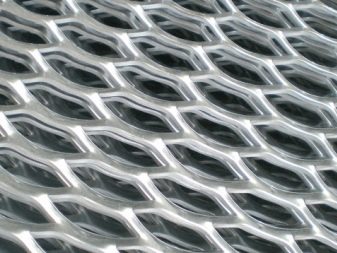

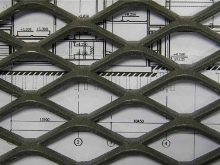

The dimensions of the cells are determined by the dimensions of the notching cutters and the pulling speed of the newly formed slots. These features of production make it possible to obtain relatively light and high-strength sheets. The original steel piece is produced, in turn, by hot rolling on the previous conveyor line. In fact, sheet products PVL-406 are a contour-structured fragment obtained from hot-rolled or cold-rolled steel. Holes covering the entire area of the workpiece are mesh.

The purpose of the fabric production is to simplify installation and finishing without significant loss of hardness, rigidity and elasticity of mesh-cellular structures.

Specifications

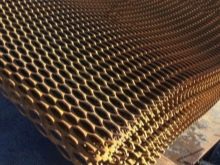

The weight of 1 square meter (1 / m2) is calculated based on the density of the steel, the size of the fragment, the thickness of the initial solid sheet from which the PVL unit was "cut", as well as the step of cutting the cell. The cell pitch of sheet 406 is 90 mm, the thickness is 12.7 mm, and the weight of 1 m2 of the sheet is 15.7 kg. However, for other denominations, the cell pitch, blank thickness and cutting height differ. The products are manufactured according to technical specifications 3626-11589 and according to GOST 8706-1978. The following sizes of fragments are mainly produced: 1000x2000, 1000x3000, 406x1200x3600, 406x1000x2500, 406x1000x2000, 250x1000 mm. The designation 406 is sometimes credited as a multiplying factor, although this is a typical marker. To combat the formation of rust, PVL is anodized - coated with zinc, chromium or copper.

In order to raise the operational parameters to a new level, the corresponding processing of the expanded metal product is carried out. The sheet fluidity is 245 MPa, and the instantaneous deformation strength is 370 MPa. The sheet thickness ranges from 0.25 mm. The maximum width of the expanded metal sheet is 125 cm. The expanded metal sheet has a mesh cell size of up to 2.4 cm. The thickness in production is set by adjusting the level of feeding a solid sheet into the machine that cuts out these cells. The amount of feeding a sheet blank for cutting holes in it is 6 mm.

Applications

The PVL-406 mesh is used in the manufacture of stairs and fences, the construction of fences, is used in the arrangement of complex marching passages at oil refineries, flooring for floors. A structural steel alloy of standard (medium) quality level is used as a starting material. It is welded without pre-preparation, since it does not become brittle during thermal tempering. PVL mesh is used to create welded structures.

At manufacturing enterprises, PVL is an element of ventilation shafts and exhaust pipelines. Reinforcement of plaster with this sheet on surfaces that were not intended for this, as well as the use of hard cement-sand pavement for reinforcement of sites, increased the demand for this subspecies of sheet rolling. PVL mesh is used in shipbuilding and mechanical engineering. Systems with filter piping use stainless steel mesh.

Anchoring the soil, for example, on embankments and along the banks of reservoirs (so as not to erode), is also carried out by means of stainless steel mesh.

Acceptance rules

PVL sheets are subject to acceptance in batches made from the same material. Each batch has the same number - products are numbered by it. The sheet size, its characteristics and appearance are checked before sending the products for storage. The batch information includes the specification number, the number of sheets in the stack, the batch serial number, conditional marking, the name of the plant and the logo of the company that owns the given enterprise.

If the quality indicators deviate from the required indicators for a quantity that exceeds the permissible rejection, check every 6 sheets from the bundle, and not every 3 sheets.

Transport and storage

Products with a nominal value of 406 are transported in stacks weighing up to 5 tons, they are tied across by means of wire with indents of 1-1.5 m between adjacent tension lines. The packaging provides for the application of the manufacturer's logo, batch number, sheet numbers and their weight. Transportation is possible by almost any land transport - taking into account the requirements for which the transportation of building materials should be extremely careful.

The fine-mesh structure does not tolerate extreme shocks and vibrations, which cannot be said, for example, about the transportation of steel profiles. In open railway wagons, sheet product of expanded metal is sent in blocks of 1 ton. When storing this mesh, linings are laid between the packs. The thickness of the lining is not less than 2, the width is not less than 10 cm.

The comment was sent successfully.