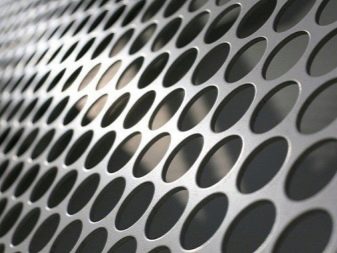

What are perforated sheets and where are they used?

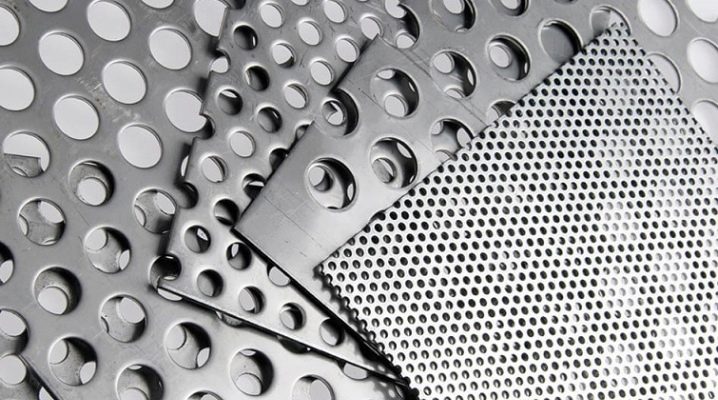

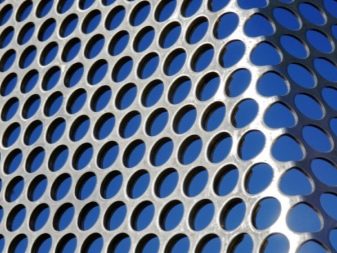

The perforated sheet differs from its solid counterpart by the mutually symmetrical and even, in rows, arrangement of holes. They can be square, oval, in the form of an elongated rounded slot, a "card club". What other perforated sheets are and where they are used will be discussed in the article.

What it is?

In fact, perforated sheet - a kind of metal mesh. It is a rough, but artistically and beautifully executed sieve, consisting of non-standard holes. Unlike a simple metal mesh, a metal perforated sheet can be made not only as a steel blank, but also from any non-ferrous metal. The perforation made in it to allow water, air and light to pass through makes these blanks suitable, for example, as a kind of garbage collector for waste water. But this area of application does not limit the use in practice of this element, which is useful in everyday life and in production.

On the market you can find sheets with more than a thousand types of holes. Not all of them are equally useful - for example, figured-slotted cuts, reminiscent of the contours of a leaf, would very soon be pressed through, as a result, the debris-retaining ability of the workpiece would sharply decrease.

Features of production

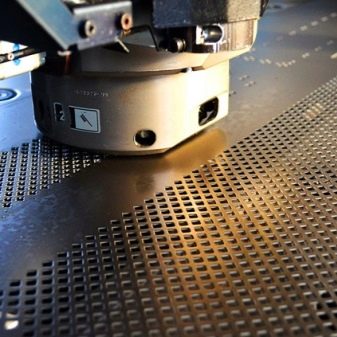

Punched sheets are made by stamping, or the so-called punching. Compared to simple drilling, used, say, in kitchen colanders, this option is among the lowest budget. However, kitchen appliances produced by stamping are very difficult to find. Sheet thickness for stamping - from 400 microns to 12 mm. In the course of making holes in solid sheets, slot-like, square, oval and other repeating holes are cut.

Like punched sheets, punchers are produced at the same enterprise. The holes on the sheet are cut using a punching mill - press. Holes of the same type are cut by means of a punch with limited functionality, which cannot be said about multi-type, compound slots. In the latter case, the sheet is driven through several stamping sessions, as a result of which repeating, but different types of holes are formed in it.

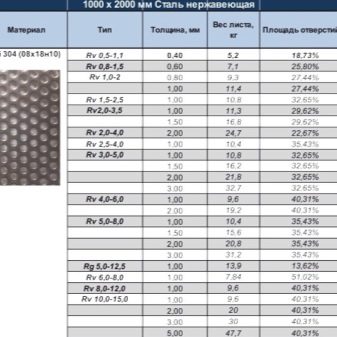

An option is possible when the holes are cut immediately over the entire area of the workpiece. To punch through thick 12-millimeter paper, press presses are used that exert very high intensity pressure during the punching process. But if ordinary rusting steel is relatively easy to stamp, then stainless steel, due to its viscosity and difficulty in processing, does not lend itself to stable and uninterrupted stamping with a thickness of 8 mm. After knocking out the holes, the rusting sheet is galvanized, and the stainless sheet is immediately sent to the next stage of production. After knocking out holes on a regular steel sheet, it is galvanized. The thickness of the zinc coating is up to 300 microns.

A stainless sheet does not need such a coating - a significant amount of chromium, for example, in the composition of AISI 304 steel or 12X18 compositions, reliably protects the iron, mainly of which the alloy is composed, from corrosion.

Specifications

Standard punched sheet cuts are produced in dimensions 1000x2000 mm, 1250x2500 mm and 1500x3000 mm. Sheet thickness - 1, 2 or 3 mm. Sometimes the length and width are indicated in meters, for example, 5x8 m.Steel perforated sheet, at the additional request of the client, can be bent, as well as welding of individual sections at the requested location (according to the drawing). But the profiled sheet is made not only from iron (steel) - aluminum, brass, copper and sheet metal from other metals and their alloys are also widespread.

For example, aluminum sheets with drilled small round (about 1 mm) are used for the production of colander. Sheets similar in hole parameters, but made of stainless steel for food purposes, are used in the production of slotted spoons and filter spoons, tea sieves. Filtration perforation for food and beverage applications requires a large number of small holes.

To determine the weight of a punched sheet, you need to know:

- the area of the cut or drilled holes - individually and in general;

- area and thickness of the original (solid, before perforation) sheet;

- the density of the alloy from which it is made;

- workpiece thickness.

Batch weight - the weight of one workpiece multiplied by the number of its identical copies. Based on this, the delivery company selects a truck with a suitable carrying capacity. For example, the weight of sheet steel with a cut in the Rv3-5 format with a galvanized billet thickness of 0.7 mm has a hole area of 32.5%, which means that it reaches 11 kg with a section size of 125x250 cm.

A thousand of these sheets already weigh 11 tons. This is enough to fill a 20-ton Scania truck by 55%.

Views

There are many types of sheet perforation - in practice, hundreds of types are used, theoretically this number is infinite. A wealth of choice is ensured by different combinations and combinations formed by alternating sections with different cut shapes in an arbitrary sequence. For example, a kind of circular perforation is used where the rows of holes are gradually shifted. Square can use, for example, offset holes diagonally. There are hardly more than a dozen specific varieties of the shape of the holes, but using a combination of their alternating parties, many thousands of versions are formed.

For clarity, it is worth giving specific examples. So, a black perforated sheet is produced from steel 3 or steel 8 of semi-calm deoxidation. St3 is a starting material for making fragments of a sieve or punching sieve, as well as a starting material for manufacturing elements of load-bearing structures. Painting with black enamel, but can be replaced with any other. To use such a sheet indoors, powder coating is used, not liquid. Galvanized sheets are manufactured in accordance with GOST 14198-1980. Zinc, unlike the enamel layer, can last 10 years longer than the enamel layer.

Corrosion-proof sheets are not painted - there is no need to hide their glossy mirror surface. Only those sheets on which, instead of stainless steel, were used only by surface spraying from it, are not painted more reliably than galvanized in thickness. Painting of such sheets should be carried out, as in the case of galvanizing - at the first signs of complete erasure of the zinc layer in certain points and areas. If you have to paint the sheet by hand, then use a primer-enamel on a thin layer of rust.

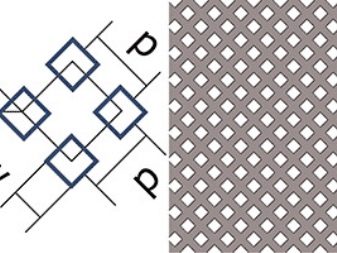

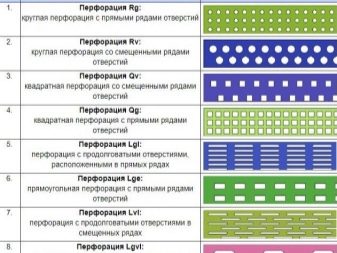

Perforation markings are represented by the following symbols.

- Rg - round holes in a straight line.

- Rv - offset rows of circular holes.

- Qg - square holes lined up straight.

- Qv is the same, but with an offset.

- Qd is the same, but with a diagonal offset.

- Lgl - long straight holes.

- Lvl is the same, but with a shift.

Example - Rv 5-8, Rv 10-15, Rv 4-6. In all cases, for round perforations, the first number is the diameter of the holes, the second is the distance between their centers.

Aluminum sheet is lightweight and relatively resistant to water and precipitation, but it has a drawback - low corrosion resistance. Hot rolled billets are easy to work with, but this type also does not resist rusting. Because of this, their use is limited only to solving technical problems. But smoothness is added to cold-rolled products - they are not inherent in the factory roughness and negligence characteristic of hot-rolled products. The decorative use of conventional steel perflists is possible only when painting.

Copper punched sheet has all the qualities, except for one - a high price. Such a blank is used only as a design solution, it cannot be a supporting structure - copper is easy to process, but it is soft, approximately like aluminum. Brass sheets are used as furniture decoration. Bending brass can result in cracking - like aluminum, it breaks easily. You can insert homemade hooks into a punched sheet with any shape of holes, for example, bent from nails or wire - and turn a section of the partition, for example, into a stand on which the hand tools of a home (garage) craftsman hang.

Applications

The area of use of punched-sheet players is diverse - they are used for the design of some tools, and as a material for fences and partitions. Thick steel trapezoidal sheet is used as treads for all steel stairs. The anti-slip floor, in addition to using, for example, a profiled sheet with a rhombic and lentil pattern (texture), is often decorated with a perforated sheet.

Blunted (in the thickness of the sheet) holes do not allow slipping, for example, for women who wear high-heeled pumps, and also create good grip on the protector of sneakers and sneakers, military boots and army boots. The use of a punched sheet for furniture, for example, for a workbench, is limited to shelves from which large tools will not slip, even when the workbench is rolled due to the powerful wheels on the legs. The listed products are only a small part of the applications for punched-sheet products.

Architecture

Sound insulation and wind protection of buildings and structures is not complete without a profiled sheet. And although these ways of using a perforated sheet relate more to construction, reconstruction (redevelopment), however, using a perforated sheet with a unique texture, you can decorate an old balcony with it in a modern way, create an original partition between rooms.

Instead of glass, a sheet of the same stainless steel, decorated in an original way, can be installed in the sheet holder (glass holder) of the stairs, on which, for example, stainless railings are installed.

Interior Design

Arrangement of partitions in an office complex of one of the floors of a multi-storey building, creation of a basis for suspended ceilings, artificial fences for stairwells, decoration of heating radiators and window structures - this is not the whole list of design work in which the punched sheet is used. Thanks to the perforated sheets, it is possible, for example, to organize and delimit the arrangement of the luminaires.

Urban environment

The punched player has found its application in the arrangement of playgrounds. In this case, its thickness will be 2-4 mm. The road fence separating the sidewalk from the roadway replaced the lattice fences, over which schoolchildren and youth climbed to cross the avenue in the wrong place. The punched sheet is also used for advertising design - for example, in the manufacture of lightbox partitions.

Food industry

Perforated sheet - the starting material for the manufacture of filtering utensils. A one-millimeter sheet perforated by punching with a gap in four directions serves, for example, for the manufacture of small-fraction manual graters and sieves for vegetable cutters that chop fruits and vegetables into a mushy consistency.

Sharpening round and oblong holes in a stainless steel punched sheet with their slight bending allows you to get a coarse grater or a cutting rotating shutter for a blender. Perforated sheets are the main element of modern grinders, the basis of which is a knife and / or a hole-pointed texture.

Trade and exhibition equipment and furniture

Using a punched sheet with blunt holes, chairs and stools, tables and racks, shelves and exhibition stands are made. To make the displayed product or someone's work clearly visible from afar, the perforated sheets of the exhibition tables are painted white. For restaurants and cafes, the perforator is used as one of the starting materials for the manufacture of flooring for bar counters, awnings and billboards.

Since elements of the urban environment are exposed to precipitation and ultraviolet light from the sun, it is better not to use painted sheets - use galvanized sheets.

The comment was sent successfully.