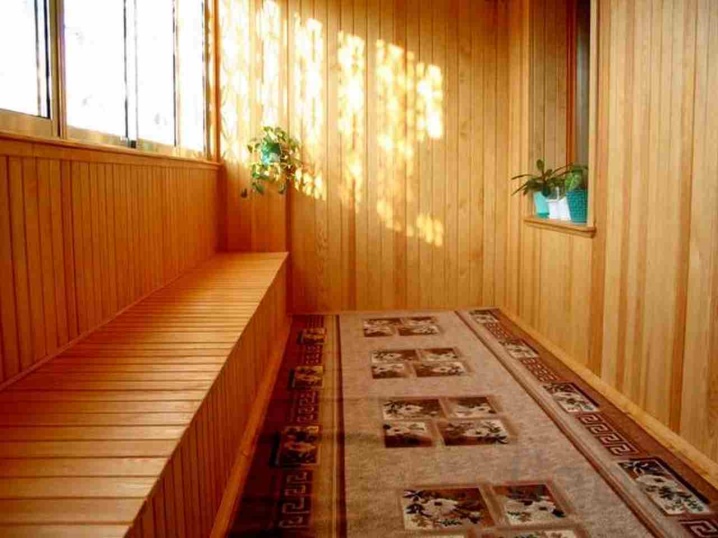

Finishing the loggia with clapboard

Lining is a functional material suitable for interior and exterior decoration. You can sheathe a balcony with your own hands, choosing a suitable interior for the panels.

Decorating a loggia with clapboard requires a minimum of effort and money.

Pros and cons of the material

Wood is a natural material characterized by strength, durability and attractive appearance. The lining made of it is suitable for finishing an open and glazed loggia. She will decorate the room in the Art Nouveau, Provence or country style. The material will look good even when a minimum of decorative elements will be used to decorate the loggia.

Lining advantages:

- ease of installation and operation;

- durability, reliability;

- ease of care of the material: it is easy to clean and wash;

- environmental friendliness, non-toxicity;

- good thermal insulation characteristics.

Natural building materials help maintain a comfortable indoor climate. In the hot season, the lining absorbs heat, and in the cold, on the contrary, retains it. Thanks to this, you can relax on the balcony not only in summer, but also in winter. This is also good in cases where indoor plants or seedlings are grown on the balcony.

Despite the large number of positive aspects, the lining has a number of disadvantages. Like any wood object, it can ignite. To avoid this, it is recommended to cover the material with special protective solutions and varnishes.

Also, the lining has a relatively low resistance to temperature extremes, it can lose its external characteristics when interacting with moisture.

Views

Traditionally, panels were made from wood only. At present, other materials can also be used as raw materials. There are several types of lining

Wooden

Oak, pine, aspen, linden, larch are used as raw materials. They differ in cost, performance, color. Conifers contain a large amount of resin, which can begin to be released when exposed to high temperatures. Such wood is softer, traces may remain on it after impacts and other mechanical influences.

Expensive varieties include cedar, oak, alder. The lining made of these trees is highly durable. In addition, it has the best aesthetic characteristics and is more resistant to weathering and precipitation.

Each tree species has a unique shade - this point is taken into account when planning the interior of the loggia.

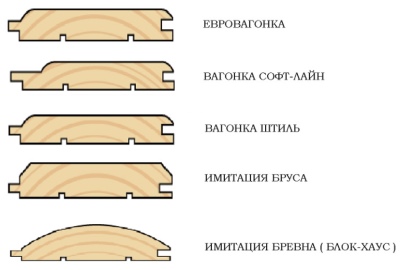

Euro lining

A kind of wooden lining, made according to European standards. It belongs to the premium class building materials, is of the highest quality and is more expensive. Euro lining is divided into types depending on size and purpose. The most common models are standard, block house, landhow, American, soitline. They differ in the specifics of installation and appearance.

Most often, consumers prefer block house. The material is resistant to environmental influences, therefore it is used for finishing both internal and external premises: it is suitable even for non-glazed balconies. On one side of such a lining is a cylindrical surface.

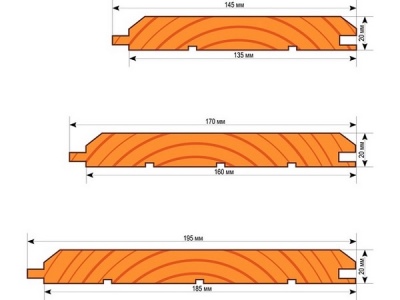

The dimensions of the products are prescribed in the requirements for this type of materials. The thickness should be 13, 16 or 19 mm, the width - 80, 100, 110 or 120 mm.Strict rules apply to the length of the panels: from 500 to 6000 mm.

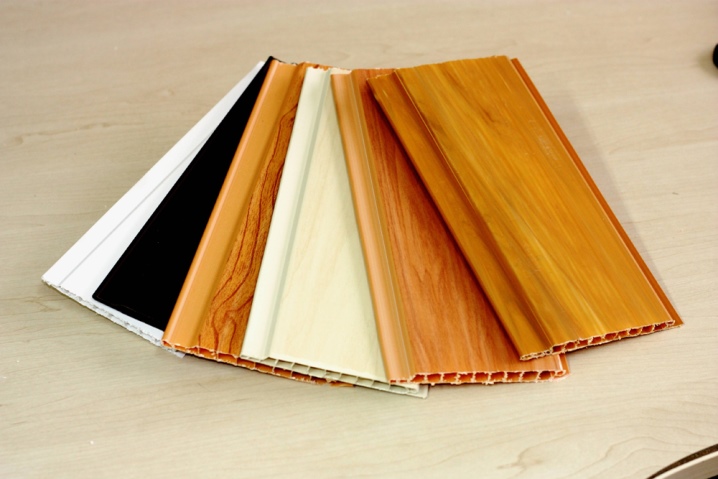

Plastic

A cheap analogue of lining made of wood. It is decorated with patterns, can imitate wood, stones. High-quality products made of polyvinyl chloride at first glance will be indistinguishable from natural panels, and their performance will be even better in some indicators.

Plastic is resistant to temperature fluctuations, retains its external characteristics under the influence of ultraviolet rays. It is characterized by moderate flammability, provides good heat and sound insulation. The price of PVC panels is lower, which makes them affordable for a wide consumer segment.

The disadvantages of the lining include the fact that it is easily deformed from external mechanical shocks.

How to choose?

When choosing a lining for finishing a loggia, take into account the external and operational characteristics. In particular, they pay attention to criteria such as material, profile and size of parts, budget for repairs. When planning to use wood sheathing, look at the type of wood and its class. In addition, the material is matched to the specific design of the room.

Classes of lining made of natural wood:

- Extra. High quality material that meets stringent requirements. Premium lining is more expensive, is characterized by reliability and increased service life. For the manufacture of panels, the best types of wood are taken.

- A. The quality of such a lining is somewhat lower, but it still has a significant service life, and is resistant to external influences. According to the requirements, the material may have a small number of defects that do not spoil the overall appearance of the product.

- V.Defective lining. The panels have blind cracks, knots up to 20 mm in diameter, as well as resin pockets. Building materials are processed at the factory using a putty.

- WITH.The material is used to decorate technical rooms, storage rooms and little-used rooms. There are spots, contrasting stripes on the surface of the panels. The size of the cracks reaches up to 5% of the total area of the boards.

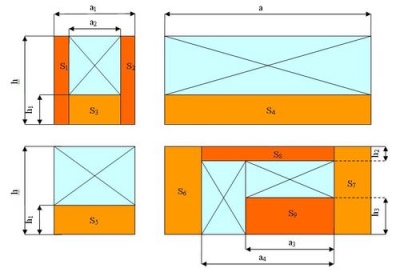

When choosing a lining, they are guided by the size of the sheathed surface, since different manufacturers create materials that are different in size. To calculate the required number of panels, the area of the room is divided by the area of the board. Next, determine how many beams are required for the installation of the lathing. The height of the room is divided by the distance between the guides and multiplied by the length; after the resulting values are added to determine the total footage.

The specificity of the installation depends on the material profile. The panels differ in the shape and size of the edges, the configuration of the grooves and locks. The lining differs in the specifics of the front and back surfaces. They can be smooth or convex and cylindrical. There are also materials with a carving effect.

Do-it-yourself inner lining

The installation of the lining can be carried out without the involvement of professionals, using the available tools. To trim the loggia, you will need an impact drill, drill, screwdriver, hacksaw, drill, hammer, ax, fasteners. When working with uneven walls, a building level is used; to take measurements, they take a tape measure, a ruler, a pencil.

Before proceeding directly to the lining of the loggia with clapboard, preparatory work is carried out. Traces of past finishes, paints, whitewash are removed from all surfaces on the balcony, and old linoleum is removed. You also need to unfasten the window slopes, baseboards, take out all the things - as a result, there will be an empty room.

The next step is the installation of the lathing and insulation. The first step is to mount two beams at the floor and above the ceiling. A rail of the required length is cut off, on which marks are made at regular intervals: holes for self-tapping screws will be located there. The bars are applied to the wall, they are installed using fasteners.

The top rail should be 10 cm from the ceiling, the bottom one 3-5 cm from the floor.

The remaining elements of the crate are mounted parallel to the installed beams. Pre-measure equal distances using a tape measure and a nylon cord. The frame is located on all walls and the canvas, the gaps between the parts should not be more than 60 cm. In the case when it is planned to insulate the balcony, thermal insulation materials are placed between the slats, after which the lining is laid.

When the battens are installed correctly, the balcony cladding will be simple. There are several types of lining laying:

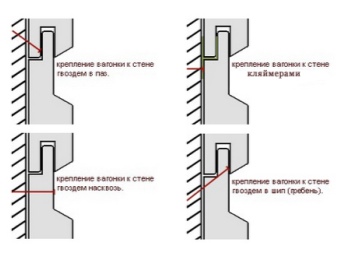

- With open mount. The easiest way to trim a loggia or balcony. Installation is carried out using nails and self-tapping screws, with which the boards are installed on the surface. The downside is that the fasteners remain visible and spoil the appearance of the panels.

- With hidden attachment. Fasteners are driven into the inner part of the groove, the heads of the nails are sunk. The most advantageous option is the use of clamps. They are inserted into the holes and screwed in with self-tapping screws. The boards are inserted into the grooves of the previous panels; the action is repeated until the loggia is completely finished.

Installation of plastic lining has distinctive features. First, the corners are installed (a construction stapler is used for this purpose), panels are mounted in them with the thin side. Then the next part is inserted into the groove - and this is repeated until the very end.

Finally, it may be necessary to cut off part of the panel, since the length of the walls does not always coincide with the total area of the products. The lining is covered with sun-resistant varnish, special protective mixtures.

A more detailed process of finishing the loggia with clapboard can be seen in the following video:

The comment was sent successfully.