Finishing the loggia with plastic panels

"Plastic lining" is the most inexpensive and practical material for the inner lining of the loggia. In addition, the panels are installed very quickly and without unnecessary dust, so you will need a maximum of one or two days to cover the room. However, when working, it is necessary to take into account some of the nuances that may arise during sheathing.

Advantages and disadvantages

Advantages of finishing:

- Simple installation. Both plastic and wooden panels have one of the easiest installation. You attach the lining to the lathing, which can be wood or metal.

- Affordable price. On average, the cost of one panel three meters high and 19.5 cm wide in construction mass markets varies from 150 to 250 rubles. At the same time, ordinary white lining is the cheapest material. Its price starts at 50 rubles and ends at 150. For example, the price per square meter of wooden lining starts at 500 rubles. The cost per m2 of decorative stone cladding is from 1000 rubles.

- Long service life. According to the warranty period, the service life of the "plastic lining" is up to 25 years.

- Environmentally neutral material. Despite the fact that PVC panels are made of plastic, the material is absolutely neutral in relation to the environment.

- Panels withstand mold and do not deteriorate from strong detergents. To clean the inside of the panel, simply remove it.

- "Plastic lining" has the property of antistatic, that is, it does not attract street dust.

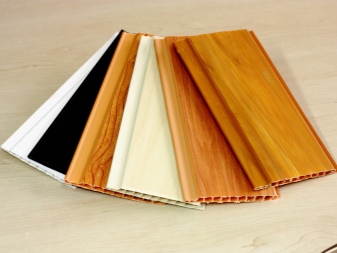

- A variety of choices. Today the store offers a huge assortment of plastic panels for finishing the loggia. Moreover, it does not end with monochromatic models. In stores you can find "plastic lining" with a pattern, wood or stone.

Disadvantages:

- The fragility of the material. PVC panels are not resistant to mechanical stress. You can even break them by pressing your fingers on them. And by touching the material with a sharp object, you risk leaving a hole on the plastic forever.

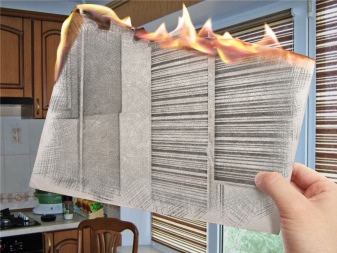

- Toxicity when exposed to sun and fire. Inexpensive and low-quality panels, when constantly heated in the sun, can emit toxic substances. This material is also toxic in case of fire.

- The material is considered the choice for finishing economy class.

How to choose quality PVC panels?

When choosing plastic panels, you need to pay attention to the following factors:

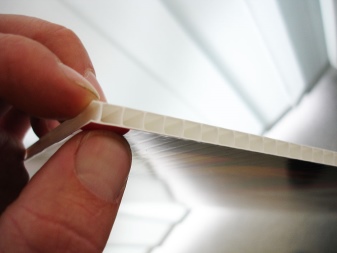

- Front surface thickness. More resistant to mechanical stress is a material with a front surface of up to 3 mm. The average Chinese model has a thickness of 1.5 mm. Products with a thickness of 2.5 to 3 mm are recognized as quality.

- The number of stiffeners and their position. More ribs will make the panel stronger. When examining their standing, pay attention to the evenness and absence of deformation inside the lining. In ordinary Chinese models, the number of stiffeners rarely goes over 20. Good manufacturers have up to 25 stiffeners per panel. High quality PVC panel counts with 29 ribs.

- Appearance and smell. The plastic panel should be flat and free from dents or scratches. Its color should also be solid, or with a high-quality pattern. In the store, you can sniff the panel. If a pungent plastic smell emanates from it, then most likely it is made of toxic and inexpensive materials.

- Also in the store, try connecting panels together. Thanks to a special groove, they should easily fit into each other. If the lining is difficult to connect, then perhaps at home you will have problems installing the material.

- The quality of the models also depends on the weight. A heavy PVC panel indicates a large presence of stiffeners, which means high quality. For example, the weight of a quality "plastic lining" differs from the Chinese one by 500-700 grams per square meter.

- The very low price of the material should alert you in the store. In most cases, this can mean that the lining is made from low-quality raw materials. At the same time, do not forget that construction markets have their own brands, which, of course, can provide a price slightly below the market price.

- Chalk content is another important factor to consider when purchasing panels. A quality product should have a low chalk content. To identify the chalk in the composition, you need to easily press down the lining in the store. Further down the line, just take a look at the fold. If the panel contains a small amount of chalk, then there will simply be no dent.

Preparatory work

The technology is as follows:

- During the preparatory work, clean the walls of the loggia from the old material: remove the ceramic tiles, if any, remove the nails sticking out of the walls, sweep out all the debris from the loggia. If the room does not have a warm floor, then a good solution would be to waterproof the loggia.

- Existing cracks and large irregularities must be covered with putty. Often, the space between the window sill and the wall is filled with polyurethane foam for greater waterproofing. After the preparatory work has been carried out, it is necessary to wait a few hours until the putty dries up and the foam reaches the required volume.

Note that sealing the loggia is simply necessary. Otherwise, you run the risk of getting a comfortable additional room that cannot be used in the cold season. In addition, if you have a warm floor, but there are drafts, then the structure will lose its properties after several winters.

- To calculate the exact amount of material, it is necessary to calculate the perimeter of the balcony and divide the resulting figure by the width of one panel. A similar procedure must be carried out when calculating for the ceiling lining. But do not forget to buy several panels in reserve, since the material is very fragile and when working without a master, you can simply damage it.

- Before work, you need to decide how you will attach the material to the wall. There are two methods for installing PVC panels: the lathing on which the lining is attached, and the frameless method - gluing the models to the wall. In the first case, you have the opportunity to put insulation between the main wall and the plastic, which is important when trimming a warm loggia. For the second option, the walls of the loggia should be flat so that the panel does not “go away” during installation due to unevenness. It is necessary to proceed from a specific situation. When installing PVC panels on glue, an absolutely flat surface is required.

- Before proceeding with the facing work, it is necessary to insulate the floor and lay tiles on it, laminate, linoleum or other flooring. It is best to install a wooden lathing, lay insulation and make a flooring from a wooden lining. For this option, laminate, parquet, linoleum, or vinyl tiles are suitable. If you want to install natural stone or ceramic tiles, it is best to level the floor with dry mix. It is important to remember that leveling must be done according to the level.

Finishing stages

Crate option

Technology:

- Before installing the lathing on the loggia it is necessary to insulate the walls of the room... Interior decoration includes sealing a concrete or brick wall using a special mixture, which includes rubber and insulation with foam panels.Styrofoam layers are easily glued to the wall using mounting foam. After that, you can close the wall with a special film that will not let air through. You can attach it to the foam using a construction stapler.

- The next step is to install a wooden lathing... To do this, you need beams with a section of 40 * 40 or 50 * 50. The calculation of the number of beams must be made according to the calculation of the perimeter of the loggia.

- First, you need to install the first bars in the corners.... To do this, you can use a U-shaped metal profile, or simply drill the boards to the wall. Instead of wooden beams, you can also find special metal profiles in the store. Their advantage is that the profile will not rot and will not absorb moisture.

It is important to know that for vertical models of their PVC or MDF, only horizontal crate can be used. The cross-batten option will be more reliable.

- After establishing a horizontal profile with a step of 50-70 cm from each other, it is necessary similar installation of vertical bars... Use a level when working.

- Next step: stretch foil-clad material such as penofol or izolon... After insulation, it is necessary to complete the insulation by covering the parapet with a special film that will prevent condensation from entering. This completes the interior decoration and now you need to move on to the exterior decoration.

- Installation of PVC panels in this case, it starts with the installation with the installation of the fixing profiles. The first panel must be mounted in the corner profile and attached on the other side with a stapler.

When sheathing with MDF panels, the work is approximately the same as with plastic ones.

See below for a master class on the installation of battens, fittings and PVC panels.

Option for glue

There is another option for work when you do not need to install the crate - attach the panels with glue. This method is necessary if you decide to save on space. Before direct installation of the panels, it is necessary to make a flat surface:

- If you do not plan to insulate the loggia, then it is enough to walk several times with putty and prime the surface of the wall... After everything is dry, apply a rubber-based water-repellent mixture to prevent moisture from leaking out and causing permanent mold in the room. After that, you can start assembling the panels.

- The work must be done with a level, and you also need to choose the right glue. For a more reliable fixation, it is better to use special liquid nails that can withstand strong temperature changes (remember that in summer the temperature on the loggia is much higher than outside, and in winter it will be cold in the room).

- In case you decide to insulate the balcony first, then you still need to install the lathing... Place the foam plates in the space and finish with the installation of insulating material. In the future, the wall needs to be sheathed. For this, you can use drywall or plywood. In both cases, the fixation must be very strong.

- In the future, it is necessary to putty the surface again.to hide uneven joints. The final stage is the installation of the panels.

Advice

Designers are advised to adhere to the following recommendations:

- Do not forget that after finishing the walls, you need to install a window sill. If the ledge on the balcony may be minimal or absent due to the lack of space in the room, then on the loggia you can afford to install a full-fledged window sill.

- On the loggia, plastic paneling is available only for walls and ceilings. A good floor covering must be laid on the floor. Among the most inexpensive: linoleum. A more luxurious option is to lay vinyl tiles or porcelain stoneware on the floor of the loggia.

- To work you will need the following tools: construction stapler, jigsaw or circular saw, level, construction stapler, jigsaw miter box.

- In the cold season, let the plastic "lie down" for about half an hour in a room with room temperature.

- The protective film can be removed after all construction work has been completed.

- When installing panels on a batten, do not forget to install thermal washers, which can be found in hardware stores. They will help to keep the sheathing during warm seasons.

- During heating (which can also happen in winter, especially on the sunny side of the house), the plastic begins to expand. Thermal washers will help keep the plastic on the crate.

- If you decide to lay an electric cable under the panels, then plan in advance the grooves from special plastic strips.

Design examples

The classic version of cladding is considered to be finishing with monophonic PVC panels. Most often, builders use white, both glossy and matte. In this case, the panels themselves may contain any ornament or drawing.

Panels for natural stone are also very popular. Such models will perfectly fit into the design of large loggias, and in small rooms they will look awkward.

Another option for large rooms is a dark shade model. Designers do not advise using them on small loggias, as they will narrow the space.

The comment was sent successfully.