How to choose paint for rust?

Metal structures are strong, durable and reliable. Their only drawback is their susceptibility to corrosion. In order to eliminate it, consider the features of the choice of paint for rust.

Peculiarities

Rust paint is a special anti-corrosion paint composition. With its help, you can not only remove existing rust on the metal, but also protect it from its reappearance. There are several types of such a paint and varnish product on sale today. They all differ from each other in the main active ingredient, in their base, manufacturer and method of use.

Some types of paint can be applied directly to rust, others require additional cleaning of the damaged area before their use. Most of these paints have a unique composition, due to which the process of further oxidation under their layer does not develop, but, on the contrary, stops. On sale you can find universal rust paints that can be used both indoors and outdoors and isolated, that is, intended for use in one place.

All paints and varnishes of this type have a strong, pronounced toxic aroma. Therefore, their use requires the use of a protective mask or respirator. It is noteworthy that anti-corrosion paints and varnishes are intended only for use on metal structures of any kind. Their use allows not only to protect the metal from oxidation, but also to improve or update its appearance, to extend the service life of the entire structure as a whole.

Views

Various types of this coating are presented on store shelves today. Anti-corrosion paints perform a protective function: they prevent oxygen and moisture from destroying metal surfaces.

They are subdivided into several varieties:

- Phosphating agents, which create a special protective layer on the surface of the metal structure. It is thanks to him that corrosion does not spread further.

- After drying, insulating mixtures turn into a film with increased strength, which does not allow negative factors to affect the metal.

- Passivating mixtures not only restore metal damaged by rust, but also protect it from its reappearance.

All types of anticorrosive paint are suitable only for those metal structures that have undergone the influence of corrosion in a small amount.Rust paints are intended for use in cases where a trace of corrosion is already clearly visible on the metal. They not only eliminate them, but also prevent the reappearance of rust.

Subdivided into the following groups:

- Priming - paint against rusty deposits. Special components in the composition react with iron oxide and form a dense protective film on its surface. If the damage from rust was small, then this film completely repairs them.

- Stabilizer paint designed to protect metal damaged by corrosion from further destruction.

- Inhibitory composition Is enamel and primer in one bottle. Its components interact with rust, destroying it, and an additional protective layer forms on the metal surface.

- Rust paint is quick-drying and therefore requires skill in use. Hammer paint has a unique composition of aluminum and zinc powder, glass and silicone oils.This spray paint dries up pretty quickly. Suitable for processing metal that has not yet been damaged by rust, and for metal structures with corrosion.

- Decorative oil paint, which contains drying oil, is sometimes also used as a means of combating corrosion. Suitable for household use only. It does not provide an opportunity to restore already damaged metal. The level of moisture resistance is very low compared to other materials.

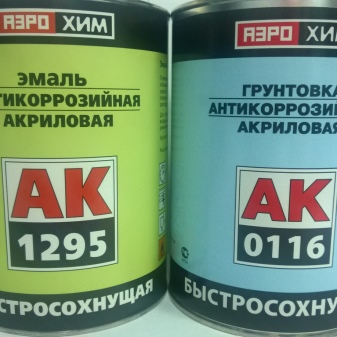

- Acrylic paints against corrosion appeared on the market relatively recently. They effectively protect metal from rust, withstand severe frosts and have a long-term protective effect.

It is necessary to choose a specific type of paint based on the type of metal, the degree of its damage by rust, as well as on the purpose that should be achieved through its application.

Color spectrum

Paintwork material with the effect of protection and restoration from rust damage is produced in a wide range of colors, it can be:

- black;

- brown;

- gray;

- yellow;

- green;

- blue;

- purple;

- gray;

- white;

- turquoise;

- orange.

Depending on the manufacturer, the color range can be much wider. So, in the line of some brands, rust paint of various shades of purple, red and brown is presented. The assortment of some manufacturers also includes chameleon-colored paints, translucent textures.

All colors can be matte or glossy, cold or warm. For metal structures of any shape, size and purpose, you can choose the ideal paint option in color.

Manufacturers: review and reviews

Many domestic and foreign brands are engaged in the production of paints and varnishes designed to protect metal from rust and combat it.

The best of all that exist today are:

- Hammerite Is the best paint for galvanized, ferrous or non-ferrous metal structures. It completely removes even serious signs of rust. It comes on sale in two types - hammer or smooth coating. This tool belongs to category 3 in 1. Customer reviews say that this composition perfectly protects the metal from rust, gives it a beautiful appearance, the paint itself is easy to apply, and retains its qualities for a long time.

- Lank Are the products of the Lankwitzer Lackfabrik brand from Germany. The range includes hammer, anti-corrosion and alkyd compounds. The manufacturer positions its product as the highest class paints at an affordable cost. Can be used to paint pipes, gates, fences and any other metal structures. Customer reviews only confirm its high quality and effectiveness in combating corrosion.

- Dali Is not just a paint, but a real enamel-primer. Evens out the damaged metal surface, prevents the development of corrosion, protects the metal from its further appearance. Buyers of these products note the ease of application, wide palette, affordable cost and good protective properties.

- Aerosol enamel in cans Kudo Is a hammer paint suitable for structures made of ferrous alloys. Eliminates traces of existing corrosion and prevents its reoccurrence. Buyers especially note the low price, ease of application and economical consumption. According to them, this enamel effectively and permanently protects the metal from rust.

- Panzer Is a wide range of anti-corrosion paint. There are hammer, gloss and anti-corrosion mixtures on sale. All of them have low consumption, high quality, wide color palette and affordable cost. Customers note the ease of application, bright and varied colors, and high efficiency in the fight against rust.

Positive reviews clearly prove that these brands of anti-corrosion paints are the best.Therefore, it is their products that are worth paying attention to in the first place.

Criterias of choice

In order for the paint for rust to correctly and fully cope with its purpose, when choosing it, it is necessary to take into account:

- The type of metal and its purpose. Metal structures made of steel or aluminum must be painted with different mixtures. The same rule applies to structures that are different in purpose. For example, for roofing, it is better to use mixtures that are not afraid of high temperatures and do not fade in the sun. But for plumbing, standard hammer paint is also suitable.

- Conditions in which it is permissible to use a specific paint and varnish mixture. This includes the maximum heating and cooling temperatures, humidity levels, and the possibility of mechanical damage. Applying paint to metal in unsuitable conditions will lead to a decrease in its protective qualities or their complete elimination.

- The nature of corrosion and the degree of protection of the paint. These two parameters are inextricably linked. The stronger and more voluminous the rust on the structure, the stronger the restorative and protective properties of the paint mixture should be. Otherwise, it will be impossible to achieve the desired result.

- Drying speed and toxicity level of the paint. If work is carried out outdoors in close proximity to water, then you should choose a mixture that dries as quickly as possible. For indoor work, it is best to use the least toxic paints, which will take a little longer to dry.

- Anti-corrosion paint color, depending on the type of structures that will be painted with it. Some metal products need to be painted in certain colors, for example, gas pipes or heating pipes. These parameters must be taken into account.

An anti-corrosion paint chosen in accordance with these recommendations will certainly help solve all problems associated with rust on metal products and their further protection against it.

Recommendations

In order to enhance the effect of paint on rust, to increase the period of its protective qualities, as well as to fully assess its merits, you should use the advice of experts:

- Before purchasing a specific type of paint for rust, you must study the manufacturer's instructions in detail. Some types of this mixture require the additional use of special solvents. If information about this is indicated on the packaging, then you must purchase two products at once and use them in accordance with the manufacturer's recommendations.

- Some types of anti-corrosion paint products are marketed by manufacturers as 3-in-1 products, however, if there is enough time, it is better to use additional products. The sequence of work should be as follows: surface cleaning, priming, painting, coating with protective enamel.

- If you plan to paint a metal structure just assembled by welding, you must first wait for the metal to cool completely. After that, the seams should be cleaned, and only then the coloring mixture should be applied.

- It is imperative to take into account the temperature outside when carrying out work, if the paint is quick-drying, and on the street it is more than +27 degrees, then the work should be postponed until it decreases. The same goes for too low temperatures. In these cases, the active components of the dye will solidify too quickly and will not be able to fully affect the metal.

- Some cans with a rust-proofing mixture indicate that the paint can be applied immediately to an untreated surface, however, experts still advise to first clean the rust-affected area and degrease it. This will allow the active substances to react faster with corrosion, and the paint itself will better adhere to the metal surface.

It is the observance of these simple tips that will help to significantly increase the efficiency of using paint from rust.

For information on how to paint a rusty metal structure, see the next video.

The comment was sent successfully.