All about gas boilers

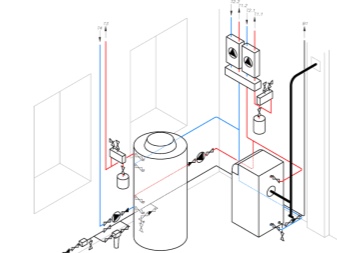

Gas boiler houses are very good and promising, but you need to know exactly the features of their construction and design. The use of such installations in apartment buildings has its own specificity. Additionally, it is worth paying attention to the boiler volume norms and the nuances of installation, to the glazing area, to the safety standards for the operation of such equipment.

Peculiarities

A gas boiler house is a system (a set of devices) in which heat is generated by burning natural or liquefied gas. The heat obtained in this way is transferred somewhere to do useful work. In some cases, steam is generated instead of simply heating the coolant.

In large boiler plants, the use of gas distribution circuits is practiced. A gas boiler house is better than a coal one in terms of productivity and ease of use.

It is much easier to automate gas heating. The combustion of "blue fuel" produces more heat than the combustion of comparable volumes of anthracite. There is no need to equip a warehouse for solid or liquid fuels. However, the gas boiler house belongs to hazard class 4. And therefore, its use in itself, as well as the internal structure, are strictly standardized.

Primary requirements

The most important rules for the construction of gas boiler houses relate to the distance to buildings and structures. Industrial installations, which, in contrast to energy and heat supply, belong to risk category 3, should be located at least 300 m from the nearest residential building. But in practice, numerous amendments are introduced to these norms. They take into account the peculiarities of communications and the volume of noise, the intensity of air pollution by combustion products. Attached boiler rooms cannot be located under the windows of apartments (the minimum distance is 4 m), only free-standing structures can be used near kindergartens, schools and medical institutions, because even the best extensions do not guarantee adequate protection.

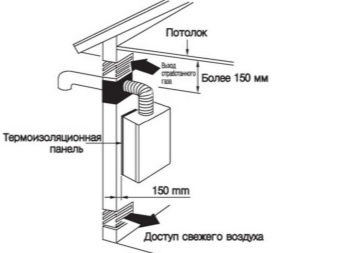

However, strict requirements are imposed on the premises. So, wall-mounted gas boilers cannot be installed in rooms less than 7.51 m3. A door with an air passage must be provided. The minimum area of this passage is 0.02 m2. There must be at least 0.45 m of free space between the upper edge of the heater and the ceiling.

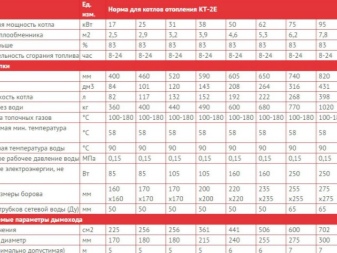

The volume norms for the boiler in terms of power are as follows:

-

if the device generates less than 30 kW of heat, then it can be placed in a room of 7.5 m3;

-

if the power is above 30, but below 60 kW, you will need a volume of at least 13.5 m3;

-

Finally, in rooms of 15 m3 or more, boilers of practically unlimited power can be installed - as far as is expedient, permissible according to fire protection standards, of course.

But it is still better to add 0.2 m3 for each additional kW of power. Strict standards apply to the area of the glazing. It is at least 0.03 sq. m. for each cubic meter of internal volume.

Important: this volume is calculated in full, without discounts for installed equipment and other exemptions. Importantly, the norm does not refer to the surface of the window as such, but to the size of the glass.

If the inspectors find that the result is adjusted taking into account the frame, partitions, vents and so on, they have the right to impose a substantial fine and even order to close the boiler room completely.And any court will support their decision. Moreover, the glass itself must be made using an easily resettable technology. We'll have to use only ordinary window sheets - no stalinites, triplexes and similar reinforced materials. To some extent, double-glazed windows with a pivoting or offset element can serve as a replacement.

A separate topic is supply ventilation in a private house with a gas boiler. A continuously open window is very primitive and outdated. It would be much more correct to use mechanized hoods and exhaust gas extraction complexes. In any case, the air exchange should ensure that all air is changed 3 times every 60 minutes. For each kilowatt of thermal power, it is required to provide 0.08 cm3 of the volume of the ventilation duct.

Given the increased level of danger, it is necessary to install a gas sensor. It is selected only among certified and time-tested samples from well-known manufacturers.

1 analyzer must be provided for every 200 m2 of boiler room.

When selecting a metering unit, both technical and commercial aspects are taken into account. It will be necessary to take into account both the fuel consumption and the costs of the coolant.

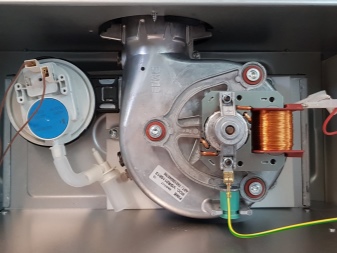

Principle of operation

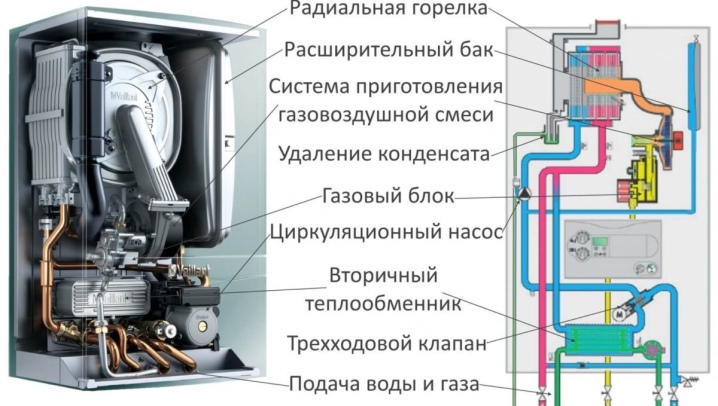

There is nothing super complicated here. The gas boiler itself is connected to the main gas pipeline or (through a reducer) to the cylinder. A valve must be provided that allows you to turn off the gas supply if necessary. Even the simplest boilers include:

-

a burner in which fuel is burned;

-

a heat exchanger through which heat enters the coolant;

-

combustion control and monitoring unit.

In more complex options, use:

-

pumps;

-

fans;

-

liquid expansion tanks;

-

electronic control complexes;

-

safety valves.

If you have all this, the equipment can operate in a fully automated mode for quite a long time. The boilers are guided by the readings of the sensors. It is obvious that when the temperature of the heat carrier and / or room air drops, the burner and the pump that provides circulation are initiated. As soon as the required temperature parameters are restored, the boiler plant is shut down or transferred to the minimum mode.

Double-circuit models also have a summer mode, in which the liquid is heated not only for heat supply, but also for hot water supply in isolation.

In large boiler houses, gas comes only from the pipeline (supply from cylinders is technically impossible in such volumes). Be sure to provide a water treatment and softening system at a large heating facility. Additionally, after filtration, oxygen is removed from the water, which can have a very detrimental effect on the equipment. Air is blown into a large boiler by a fan (since its natural circulation does not provide all the needs), and the combustion products are removed using a smoke exhauster; water is always pumped by pumps.

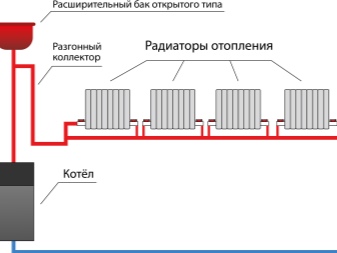

The coolant enters:

-

industrial installations;

-

heating batteries;

-

boilers;

-

warm floors (and after going all the way, it returns to the starting point - this is called a closed cycle).

Species overview

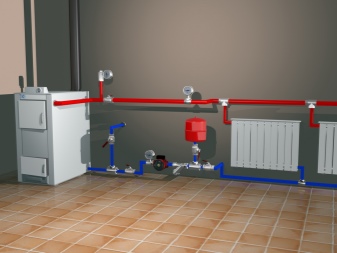

On a small area (in a private house or a small industrial building), a mini-boiler room is most often used; both power and dimensions are small. You can put such a device in almost any convenient place, as long as the safety standards allow. The minimum area of a room is 4 m2, while a ceiling height of less than 2.5 m is unacceptable. The mini-boiler room is mounted only on flat walls with sufficient load-bearing capacity.

In large cottages, however, a cascade-type boiler room is more convenient. It also allows you to serve at the same time and outbuildings. The most powerful samples are able to pull heat supply and hot water supply for several cottages at the same time.Multiple boilers and / or boilers can be easily installed at once to further increase heat production.

Water is supplied to the heated floors, to the pool, to the ventilation system using hydraulic dividers.

Traditional wall-mounted boiler rooms are not suitable for an apartment building - their capacity and other technological parameters are paradoxically small. In some cases, boiler plants are located on the roofs of heated buildings. Rooftop boiler rooms are quite sophisticated and powerful to meet all the needs of consumers. The main benefit in installing them is minimizing the distance between the point of heat generation and radiators, underfloor heating, and other appliances. As a result, unproductive losses of heat energy are noticeably reduced, and the practical efficiency increases.

Another advantage is the reduction of technological loads, due to which repairs and maintenance have to be carried out much less frequently. Autonomous boiler systems on the roofs are equipped with thermostats that allow adjusting the parameters of the coolant to the actual weather. Industrial boilers are called high-capacity boilers, sometimes reaching several tens or even hundreds of MW. They are additionally divided into heating, production and combined subgroups.

Industrial boiler houses, like all others:

-

are constructed in outbuildings;

-

carried out to the roof;

-

placed inside buildings;

-

are located in separate structures (all - at the choice of engineers).

Some of these systems are modularized (assembled from off-the-shelf components, making it easier to get started). Of course, any mobile boiler house has a modular structure. It is always easy to bring it to a new place and start work there on the fly. There are completely mobile installations (mounted on a transport chassis), as well as stationary systems, which still require a special foundation.

Mobile boiler houses, like stationary ones, can operate on hot water, heating or combined types. Power ranges from 100 kW to 40 MW. Regardless of these nuances, the design is thought out in such a way that the most efficient work is ensured and the minimum amount of human effort is required.

Multilevel security systems are required. But it is also worth considering that some modifications can run on liquefied gas.

It can be used both on its own and together with ordinary natural gas. In the second case, the presence of switches or resetting according to a certain scheme is provided. The use of liquefied fuel allows for maximum autonomy (without connecting to the gas pipeline). It will be much easier to prepare a project and agree on it than when using traditional gas. However, at the same time:

-

it is necessary to equip a gas storage facility, which must be carefully worked out in the technical and design plans;

-

liquefied natural gas threatens an explosion and requires complex protective measures;

-

due to the high density of propane-butane, in comparison with air, it is necessary to provide complex, expensive ventilation;

-

for the same reason, it will not be possible to equip a boiler room in the basement or basement.

Design

What has already been said is enough to understand that drawing up a project for a gas boiler house is far from easy. It will be scrupulously checked by state inspectors, and the slightest deviation from the norms will immediately mean the rejection of the entire plan. Engineering surveys are carried out strictly taking into account the materials of geodetic and engineering exploration of a specific site.

The required amount of current supply is agreed with the RES or other resource supplying organization. The parameters of water supply will also have to be coordinated.

A package of design materials is also prepared taking into account:

-

parameters of sewer communications;

-

town planning plans;

-

technical conditions for connection to general-purpose networks;

-

permits issued by regulatory authorities;

-

documents of title.

Even before the key work on the project, the so-called main technical solution is being prepared. In addition to it, there should be sections such as:

-

justification of the feasibility of investments;

-

feasibility study;

-

expert materials;

-

design supervision documentation.

The design sequence is as follows:

-

elaboration of a detailed wiring diagram;

-

preparation of specifications;

-

drawing up an energy balance;

-

assignments for related organizations for the arrangement of networks;

-

three-dimensional modeling and coordination of its results with the customer;

-

formation of design materials taking into account the virtual model and its development;

-

coordination with the controllers (if everything is done correctly, they will give their consent);

-

the formation of a working project, which will already be guided by the builders;

-

supervision over the implementation of practical work.

Mounting

Installation of boiler equipment under the residential area of the house is not allowed. Therefore, not in every part of the basement it can be done freely. Optimal heat supply is provided only by low-pressure complexes. They can be placed on the ground floor or underground. But it should be noted that experts clearly prefer installation in a separate building.

Equipped with a mixing unit, you can use all the possibilities that the buffer tank provides. But first you have to calculate everything. Modular industrial boiler rooms almost never require a strong foundation.

However, you will have to prepare the foundation for them in any case. They are guided by the type of installation and the magnitude of the load that has arisen.

The most reliable solution is a banal reinforced concrete slab. Important: a separate base is required for chimneys. The place for installation is chosen in accordance with SNiP. It is best to place the equipment where there is already gas, water and drainage. In the absence of such communications, it is necessary to look at where it will be easier to do them.

Preparing for the installation itself, they once again double-check the projects and estimates. The installation site must be aligned and free of anything that might get in the way. They take into account where to place access roads, temporary technological structures. A sand and gravel layer is poured under the foundation, contours for drainage are prepared. Backfilling and compaction of soil is carried out up to 0.2 m; then crushed stone is poured, concrete is poured and a layer of asphalt concrete is formed.

Pumping systems can play a big role; it is worth choosing those that are designed for quick installation. They are also more aesthetically pleasing than chaotically assembled from different parts. Important: if during installation air exchange is provided not 3, but 4-6 times per hour, the owner will only benefit. The ventilation ducts must be sealed. At the end, commissioning works are carried out.

Operational safety

The easiest way to navigate is the labor protection instructions valid for large boiler complexes. Before starting work, you need to make sure that all components, measuring and control systems are in good working order. Unauthorized people should not be allowed into the boiler room, drink any drinks or eat any food. If any deviation occurs, work should be interrupted immediately and reported to someone.

It is impossible to accumulate in the gas boiler house foreign objects and material values that are not needed for its operation.

For personal and fire safety reasons, the gas supply must be cut off if:

-

a violation of the lining was found;

-

power is disconnected;

-

the activity of control devices and systems is disrupted;

-

an alarm has been triggered;

-

an explosion or obvious gas leak has occurred;

-

indicators of counters and sensors indicate abnormal operation;

-

the flame went out without natural shutdown;

-

there are failures in traction or ventilation;

-

the coolant has overheated.

Every day, you need to inspect the electrical cable and check its insulation. If any device malfunctions, it must be taken out of service. To maintain fire safety, an internal water supply is required. Spray jets should reach all points of the room. The cleaning material is disposed of in a strict manner.

Additionally you need:

-

have fire extinguishers of any suitable type;

-

have a supply of sand and other fire-fighting equipment;

-

equip the room with a fire alarm;

-

prepare evacuation schemes and contingency plans.

For the device and principle of operation of a gas boiler room, see below.

The comment was sent successfully.