All about block boiler houses

The CHPP communications are not always connected to the facilities and various premises, then hot water supply and heating is carried out using an autonomous block boiler room. Since the structure is usually located close to the building, heat loss is noticeably reduced. It does not require the presence of an operator supervising the work, everything happens automatically.

One of the main conveniences is the mobility of the modular boiler room, there will be no difficulties when connecting to another room or when changing location.

Peculiarities

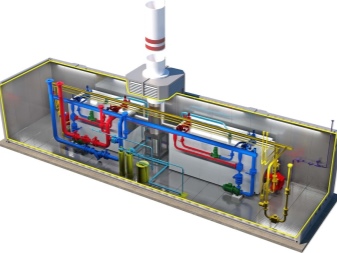

Block, or modular, boiler rooms are steam or water heating stations constructed from one or more blocks (modules). The complete set can be different, it all depends on the customer's requests. Although modular boiler rooms are portable, they are still equated to capital construction projects. The developer, in order to avoid fines, must obtain permission to manufacture and install the structure.

The main advantages of modular boiler houses:

- installation in areas with constant seismic activity;

- quick installation;

- the ability to restore, add or replace blocks;

- the possibility of transportation and installation in another place;

- no maintenance personnel needed, the design is automated.

There are also disadvantages:

- construction costs increase if the station is located indoors;

- thermal power is limited;

- a separate site for installation is required;

- there is very little space inside the block-modular boiler room, therefore, very little space remains for equipment maintenance.

The principle of operation of a modular installation is identical to that of a conventional stationary boiler house - fuel burns in boilers and heats the coolant, which then enters the facility. Through the return line, the coolant returns to the boiler room and heats up again. Continuous circulation takes place with the help of pumps.

Despite the ease of use, modular technology is dangerous and complex equipment, especially when gas is used as fuel. Only professionals need to entrust the design, installation, maintenance.

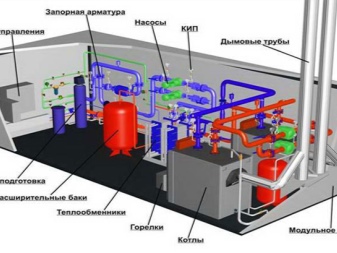

Equipment

The selection of block-modular technologies is always an individual project that is developed under certain conditions. It depends on what power the boilers will have, the type of fuel, automation, and so on. The boiler room device may include additional equipment, for example, storage tanks, a technical deaerator for liquid purification, water heating boilers, and more.

The standard equipment is as follows:

- pump equipment;

- boiler room - a building made of non-combustible building materials;

- boiler plants - steam, water heating or combined boilers;

- gas installations and chimney pipes;

- heat exchange structures;

- water preparation and purification devices;

- automation system.

Species overview

Depending on the device and design, boiler rooms are divided into 2 types.

- Stationary - productivity is higher, since the connected heat generator can be of any power. Here it is allowed to connect boilers into one network. Any fuel can be used. Easy to remount for a different type of coolant. Ready-made automated stationary installations are brought to the site and unloaded using a truck crane. Installation is carried out on the foundation.

- Mobile - transportable modular mini-boiler rooms are suitable for rooms up to 5000 square meters.It is impossible to complete such a structure with additional systems, since its capacity is not higher than 500 kW. Installation is quite simple, and additional preparation is not required for it.

According to the degree of automation, block boiler houses are divided into several types. The following options are distinguished:

- automated - are used most often, in this case, the intervention of workers is practically not required;

- mechanized - additional mechanisms are installed in them that make it possible to facilitate the work of people, for example, conveyor belts, coal crushers;

- manual - in such boiler rooms all modules are provided for manual work.

By type of fuel

- Gas - they run on natural fuel, which makes such mechanisms very environmentally friendly, and also saves resources. The only drawback is the high cost of the installation, but there is no need for equipment of large sizes for fuel supply and slag removal. In some types of gas boiler houses, diesel fuel is additionally used - it goes as a backup.

- Liquid fuel - they function thanks to resources such as oil, diesel fuel, fuel oil or waste oil. No permission is required to start work, which distinguishes them from all other types.

- Solid fuel - the main advantage is considered to be low labor costs. However, there are also disadvantages - additional fuel supply systems, ash and slag removal are required. These boilers use materials such as coal, peat, firewood, as well as compressed wood waste.

- Electrical - are characterized by increased efficiency - more than 90%. They are very easy to install, but have a rather high operating cost.

By arrangement of elements

All modular installations are divided into 2 categories:

- there must be two boilers, which are operated as a single source of energy;

- there are boiler houses with one heat source, this includes all other boiler houses that do not fall under the first category.

Boiler rooms can be located in the most unusual places, this also allows them to be divided into some types.

Most often, the following are distinguished.

- Rooftop. Roof-mounted to save space. The main advantages are that there is no need to build a high chimney, select a separate piece of land, or build a heating main. The main disadvantage of roof systems is the different "shelf life" of the building and the boiler room; replacement of equipment will be problematic in the future.

- Attached. As a rule, it is installed near the outer wall of the heated object. It has a large number of restrictions - it cannot be installed for rooms in which more than 50 people are at the same time; thermal power should not be higher than the standards established for a particular building; there must be a separate exit to the street.

- Built-in. It is installed directly in the building, but also has many restrictions, like an attached block boiler room.

- Freestanding. The best option for heating multiple buildings. Such a boiler room allows you to save the useful space of the building itself. It is undesirable to locate the unit too far from the object, because in the winter season the heating main may freeze. And also a far-standing structure will have a large heat loss.

By type of coolant

- Steam. Steam is used as a heat carrier, usually industrial enterprises use such installations.

- Hot water. The coolant in such stations is water heated to 95-115 ° C. They are used for heating and supplying hot water to residential and industrial premises.

- Combined. Both steam and water heating boilers are used in these designs.

- Thermal oil. Such systems use diathermic oil heated to 300 ° C.

Design

The design of a block-modular structure begins with the development of sketches, construction of diagrams and drawings. It takes into account the wishes and requirements of the buyer, as well as the heat supply of the building as a whole. Be sure to pay attention to the number of rooms where the radiators and the boiler room itself are located.

This is called a preliminary draft, which will be further modified and corrected.

In the next step, the required power of the boilers is calculated. To select the optimal design, the climate conditions in a particular region are taken into account, how many people use hot water daily.

A place is selected where the construction of the block module will take place. For easy maintenance, the site should be located in an accessible place. Many buildings have a large and comfortable roof on which the system can also be positioned. At this stage, the strength of the foundation is taken into account and how heat and hot water will circulate from the boiler room to the room.

The most crucial stage is the development of the scheme, it is here that most of the nuances are resolved. Already according to the master plan, costs will be estimated and plans for narrow-profile specialists will be drawn up. For the development of projects, such programs as "Avtodesk" and "ZVSOFT" are used - they allow you to take into account premises with high accuracy, there is also the possibility of combining engineering structures on a single scheme. These programs have a 3D function for creating volumetric models.

The last point is the safety check. This is done by special commissions of experts, they issue a permit, without which work cannot begin.

Application

Block-modular boiler plants are used to heat and supply industrial and residential buildings with hot water. A modular installation can serve both one and several buildings at the same time, and sometimes a small area or settlement.

Steam modules are used to generate technical steam, which is necessary for the processing of metals or concrete, for steaming various containers, in the manufacture of plastics and products. A modular system cannot be used if a high boiler output is required, but the installation of several blocks is impossible - the boiler simply does not fit into the module.

The comment was sent successfully.