Description and arrangement of mini-boiler rooms

It is not always possible to connect a building to central heating or to allocate a separate building for a modular boiler room. Most often this is difficult, and it is in this case that mini-boiler rooms come to the rescue. Such an unusual system is placed in a special container that can be placed at home or in the yard.

However, it is important to connect it correctly.

Peculiarities

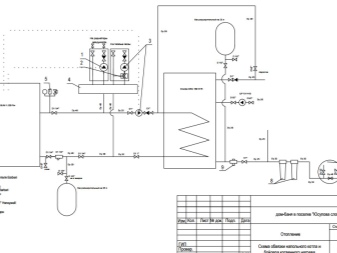

A mini-boiler room is a small, self-contained unit for a private house that provides heat and constant hot water supply. It looks like a container with the necessary equipment inside. The maximum power of this design can reach 0.5 mW. The standard equipment is as follows.

- Hot water boilers. It can be one, but there are models where two are connected into one structure.

- Circulation equipment. Powerful pumps are used to provide the system with the correct pressure.

- Smoke removal system, slag and ash removal.

- Automation system. It is with its help that the work and all processes are controlled. In modern equipment options there is a remote control function - by SMS messages or using an Internet connection.

The work of a small boiler room begins with heating the coolant in the boilers. It is heated to a certain temperature and then pumped to the connected building. The automation system ensures the constant operation of the boiler room without interruptions.

From which type of boiler was selected by the user, the fuel supply will be carried out by pumping transmission using augers or vibration. How long a mini-boiler room can operate independently will depend on the type of fuel.

Unlike solid fuel boilers, where constant human work is required (adding coal or wood), liquid fuel, gas or pellet boilers do not require constant maintenance.

By type, the systems are divided into 2 types.

- Open - its installation is cheaper, the operating costs are higher. Here, the coolant is in contact with air, respectively, heat is partially lost.

- Closed Is a more popular scheme. It is sealed, so the loss of heat is minimal, but the installation process is more laborious. Heated in the system, the coolant circulates thanks to the pumping unit.

Varieties

Solid fuel

This type of modular boiler houses runs on wood, compressed wood waste, pellets. The solid fuel system is selected according to the instructions and requirements of the customer - the required power and heating capacity are selected.

The tanks for the location of the fuel also differ, it all depends on its type:

- pellet tanks are equipped with additional screw conveyors or vibration;

- for granular fuel, a special tank is mounted on the roof of the tank;

- for a wood-burning boiler room, a pyrolysis boiler is installed, in which firewood and volatile substances emitted by them are burned separately - this system minimizes the stay of a person at the workplace.

The automation system includes functions that prevent overheating and provide pressure relief if necessary. Pellet boiler rooms are one of the most profitable heating options if there is no possibility of connecting gas equipment.

Such a mini-boiler room will not take up the useful area of the living space, and the automatic mode can be maintained for up to several months.

For coal heating

Mini-boilers fueled by coal. The advantages of this design:

- simplicity of the system, due to which the connection is carried out in a very short time;

- maintenance and repair work can be performed by the user independently;

- if necessary, the container can be easily installed in another place;

- reliable system, during transportation the risk of damage is minimal.

Subject to the maintenance rules, the service life will be as long as possible. In some modern models, the autoloading function of fuel allows the mini coal boiler to operate in an autonomous mode. The main drawback of the design is the fuel tank - it must be large, and this will require occupying the usable area of the house.

Gas

Natural gas or propane-butane-fueled system. Unlike previous mini-boiler rooms, it does not have such disadvantages. Differs in installation according to the rules of GOST and SNiP. Periodic maintenance and temperature setting are required for continuous autonomous operation.

Some models have a thermal sensor, thanks to which the temperature of the coolant is automatically regulated. Gas is a cheap type of fuel, making the design quite economical.

Installation and connection takes about a month, since official registration is required.

Liquid fuel

A fairly common type of boiler room. It works on all types of liquid fuel, and it is also possible to convert it to work on liquefied gas. If the heated room is large, it is possible to install an industrial boiler. The pumping equipment makes the fuel supply automated.

The main disadvantage of this type of boiler is that fuel is consumed in large quantities, which requires a spacious storage tank.

The tank is installed in a room with good heating or in the ground below the freezing level, and this is additional time for work.

Arrangement rules

Depending on the type of fuel chosen, the location requirements can be basic and specific. The first include the following.

- The permissible maximum number of boilers per room, regardless of its size, is 2 pieces.

- Installation in a room with flammable materials is not allowed. The walls should be brick or concrete, and the final decoration should be done with putty or ceramic tiles. The floor is filled with concrete or covered with metal.

- The chimney and ventilation systems must be suitable for the selected equipment. Increased requirements are imposed on the ventilation structure of the gas-fired boiler house. According to the standard, air renewal should occur at intervals of 20 minutes.

- A prerequisite is the presence of at least one window and door swinging open towards the street. Also, according to fire safety rules, it is possible to install a second door leading to the utility room.

- Based on the size of the installed inventory and taking into account the additional space, the area of the room is calculated for ease of maintenance.

Specific rules for the installation of a gas mini-boiler room.

- If the power of the boiler does not exceed 30 kW, then a separate room for equipment is not needed. Accommodation is possible in a kitchen with good ventilation, where the volume of the room will be at least 15 cubic meters and the ceiling height is at least 250 centimeters.

- The main requirements for gas boilers are to prevent gas leaks, so the width of the window is at least 50 centimeters, and the door is 80 centimeters.

- It is important to remember that the installation of a gas mini-boiler room is unacceptable below the level of the first floor of the room, since the gas is heavier than air. In the event of a leak, it accumulates, and it is quite problematic to remove it.

If the power is above 30 kW, then a separate room is needed, the construction rules of which are described in the building codes:

- the foundation must be poured separately from the base of the house;

- a strictly defined amount of sand is added to the concrete solution for the foundation;

- an additional foundation is poured for the boiler, towering 20 centimeters above the total;

- also under the boiler you need an additional tile or slate covering, which has a projection of 10 centimeters;

- there must be a sewerage system for draining the coolant in the event of an accident;

- you cannot clutter up the space around the equipment by 70 centimeters;

- the limit of fire resistance of the finish is 0.75 hours;

- the presence of a gas detector is required.

The gas boiler must be accompanied by a certificate stating that the unit meets all safety requirements.

For solid fuel systems, a non-residential premises or a separately built one is selected. The interior decoration of the building must also be made of fireproof materials. The distance from the firebox to the wall is 120-150 centimeters. From the walls to the boiler - a gap of at least 100 centimeters.

Any extensions above the boiler room itself are prohibited. There must be a powerful air supply from the street. If the boiler room is located on the ground floor or on a lower level, it is mandatory to install a door opening towards the street.

If coal is chosen as a solid fuel, then the existing electrical wiring must be protected from the ingress of coal particles in order to avoid an explosion (it is possible at a certain concentration).

Installation of a container for liquid fuel is easier, there is no need for special permits and certificates. It can be mounted both in the building and in the yard. The volume of the installation room must be at least 4 cubic meters.

If external ventilation is installed, then for a power of 1 kW of air, 8 centimeters in a cube are needed.

Review of the mini-boiler room "Prometheus" in the next video.

The comment was sent successfully.