What and how are bricks made of?

There are many advantages that make brick one of the most sought-after building materials. In addition to standard sizes and simple shapes, this artificial stone boasts strength, durability and beauty, which is why it has been used for a very long time and almost everywhere.

Also noteworthy are the technologies with the help of which the brick is made - as a set of processes that make it possible to obtain a material with all the characteristics the customer needs.

Composition depending on the type

Among all types of bricks, two are the most popular - ceramic and silicate, also called red and white, respectively.

They differ in the following features.

- The main component of fired ceramic bricks is clay. Such material has an aesthetic appearance, dampens noise and perfectly stores heat in the room.

- The composition of silicate bricks, made under the influence of high pressure and steam, provides for the presence of sand and lime. Compliance with the technology allows you to get durable and inexpensive products that can withstand changes in temperature and humidity.

It is also necessary to highlight refractory bricks made from chamotte with the addition of coke or graphite - components that significantly increase its strength.

Another topical variety is facing, the production of which involves the use of cement, limestone and a pigment ingredient. Such a brick, made by pressing technology, has not only an aesthetic appearance, but also an impressive service life.

Given the greatest importance of the red and white varieties, they should be considered in more detail - which will be done next.

Ceramic

The main ingredient of this type of brick is ordinary clay. It is a mineral mass that:

- becomes plastic when water is added to it;

- keeps its shape during drying;

- hardens as a result of firing, acquiring strength comparable to natural stone.

The origin of the clay used deserves special attention. Depending on the depth, it can have different properties - both suitable for brick production and not meeting the established requirements.

If we single out the component that most often forms the base of the clay, then it is kaolinite - one of the hydrous aluminum silicates. Also, the composition of the raw materials used may include montmorillonite, illite, quartz and other minor ingredients.

In addition to clay, ceramic bricks are composed of other components that are additives. They are used to impart certain properties to manufactured products, and the main ones are the following.

- Emaciated - ash, sand, slag. Promotes better mass formation and less shrinkage.

- Burn-out - sawdust, powdered coal or peat. They increase the porosity of the material, which naturally reduces its density.

- Coloring - as a rule, metallic oxides. They give the products the desired color or shade.

In addition, it is worth mentioning the iron-bearing ores and sandstone, the use of which allows you to effectively control the firing temperature.

Also, plasticizers can be used - additives that minimize the likelihood of cracking of the ceramic material.The specific amount of each of the listed ingredients is determined by customer requirements and / or manufacturer policy.

Silicate

The production of white brick involves the use of three mandatory components, the list of which is as follows.

- Sand... It can be of both natural and artificial origin. It is desirable that the grains used are uniform and have a size of 0.1 to 5 mm. Of no less importance are the surface features of the grains of sand (in the presence of sharp corners, they provide better adhesion). A prerequisite is the preliminary cleaning of the material from foreign inclusions.

The recommended proportion of sand in silicate bricks is 85 to 90%.

- Lime... To obtain this component, raw materials are used, which are characterized by a high content of calcium carbonate (90% or more) - first of all, limestone and chalk. Before firing at a temperature of about 1150 ° C, the prepared rock is crushed to a size not exceeding 10 cm. Upon completion of the listed procedures, lime is added to the composition of silicate bricks (the optimal value is 7%).

- Water... This ingredient is needed to solve two main tasks - slaking lime and imparting plasticity to the formed mass. It is used at all stages of the manufacture of silicate bricks.

Often, the production of the described products involves the use of additional components necessary to give the product the desired characteristics.

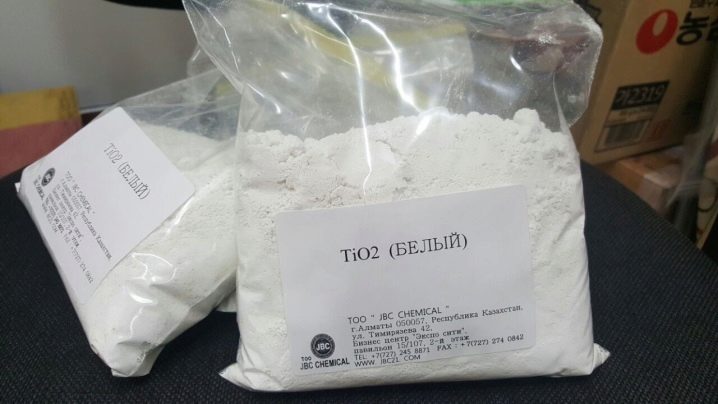

- Chemical compounds... An example is titanium dioxide, due to which silicate bricks remain white for as long as possible.

- Components that increase frost resistance... Most often, to solve this problem, industrial processing products are used, which make it possible to reduce the thermal conductivity of the material by 10-12%.

- Dyes... They are used in situations where a manufacturer needs to give products a specific shade or tone.

Expanded clay sand deserves a mention - an additive that can simultaneously solve two problems at once. In addition to a noticeable increase in the thermal efficiency of silicate products, it gives them a beautiful coffee color, thanks to which they look more solid.

Production technology

Depending on the type of bricks produced, their production has its own characteristics. This is due to the specificity of the ingredients used, which requires the use of various technological processes.

Red

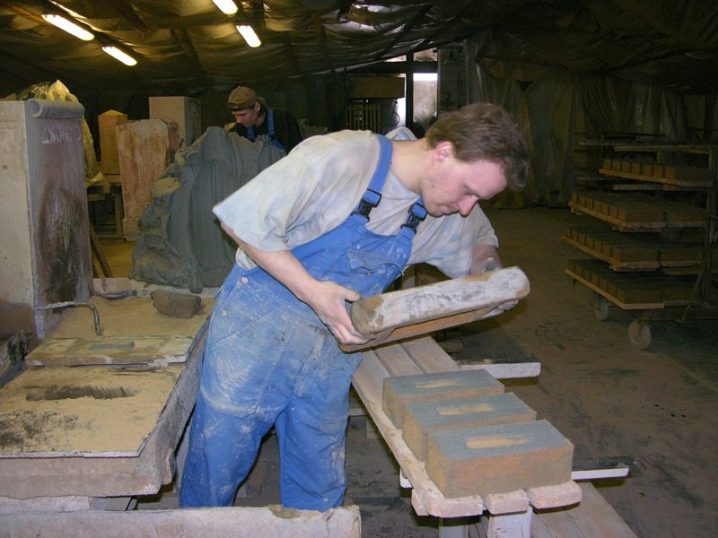

There are two main methods for the production of ceramic bricks - semi-dry molding and plastic. The latter, which is more popular, involves the step-by-step solution of the following tasks.

- Preparation of the main component - clay. It is allowed to include additives in the mixture - no more than 1/3 of its total amount. In this case, the fraction of the main ingredient should not exceed 1.2 mm.

- Transfer of the prepared mass for further molding.

- Division of a common array into standard sizes.

- Drying of ceramic bricks.

- Perforation of products (relevant in situations where products need to be made hollow).

- Burning. This type of processing provides for a smooth change in the temperature in the furnace (first upwards, and then vice versa). Following this rule allows you to avoid the appearance of cracks on bricks due to sudden temperature changes.

As for the production of ceramic bricks by the method of semi-dry molding, it implies the following procedure:

- preparation of raw materials and their grinding;

- drying and re-crushing;

- slight humidification with steam;

- re-drying;

- removal of the last traces of moisture from ceramic products.

It is reasonable to mention the production of red brick at home: in this way it is quite possible to make a full-bodied "raw" variety of this material.

To solve such a problem, it is necessary:

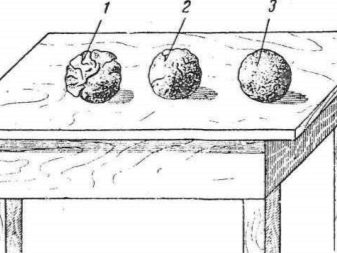

- make a ball from a homogeneous piece of clay, previously moistened with water;

- carefully inspect the sample after 4 days - for the presence of uneven shrinkage and cracks;

- if there are no visible defects, the ball must be dropped to the ground;

- if the sample does not pass the strength test, its composition must be reinforced with appropriate additives.

Upon completion of all preparatory procedures, the mixture must be distributed over the forms made of wood. Finished ceramic products will be left to dry in the shade, after which they can be used for the construction of light one-story buildings.

To make surfaces more durable, it is advisable to cover them with paint or high-quality cement mortar.

White

One of the main features of the manufacture of sand-lime bricks is the complexity, which does not allow solving this problem at home. In particular, this is due to the impressive list of necessary equipment - conveyors and conveyors, crushers and batchers, mixers and autoclaves, cranes and loaders.

There are two main production methods for the products under consideration - drum and silo.

Silicate brick manufacturing technology includes the following stages:

- checking and preparing the main components - sand and lime (the first is separated from large inclusions, and the second is crushed);

- mixing of components followed by settling in the bunker;

- grinding the mixture and adding water to it;

- slaking of lime, carried out in a drum or silo (determined by the selected production method);

- removing moisture from sand;

- molding with a press;

- steam treatment in an autoclave (recommended temperature - 180-190 ° С, pressure - 10 atmospheres).

At the final stage, the temperature and pressure are gradually reduced. Upon completion of all procedures stipulated by the technology, ready-made sand-lime bricks are packed and sent to the customer.

Firing types

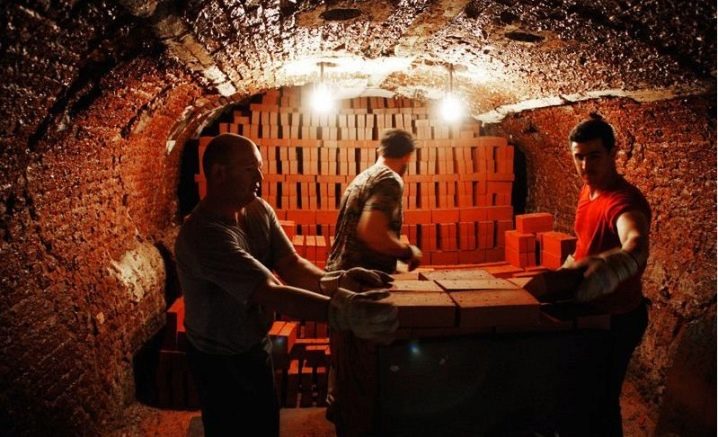

The process of heat treatment of ceramic bricks, called firing, deserves a separate consideration. It represents the final stage of the production of these products and provides for the presence of 3 stages - heating, firing itself and cooling.

- The bricks are heated to 120 ° C to remove the remaining water from them.

- To eliminate inclusions of organic origin and the last traces of moisture, the temperature is raised to 600 ° C, and then to 950 ° C, which gives the products additional strength.

- Upon completion of hardening, the bricks are cooled, gradually lowering the temperature.

If the technology is followed, a product with a uniform structure and an orange-red tint will be obtained.

I would also like to mention two types of devices used to solve the problem described above.

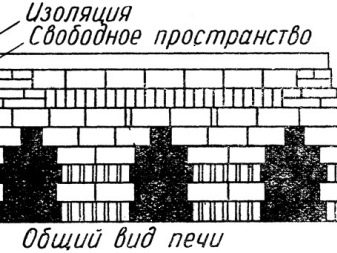

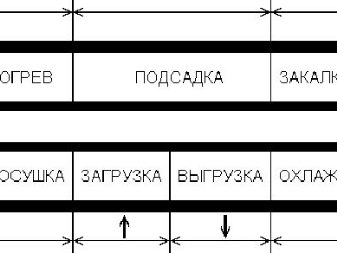

- Tunnel... It is a long sealed furnace, consisting of 3 chambers, inside of which rails for transporting ceramic bricks are laid. In the first chamber, the products are dried, in the second - firing using burners, and in the third - cooling.

- Annular... The design of this furnace assumes the presence of a large number of separate sections that have their own heat source and are placed in the form of a ring. Its peculiarity is that the bricks go through all the firing stages without leaving the confines of one chamber. So, the adjacent compartment provides initial heating, calcination is carried out due to its own heat source, and the cooling of the product occurs under the influence of the next section.

Thus, knowledge of brick production technology makes it possible to obtain a strong, aesthetic and wear-resistant material from fragile and pliable raw materials, which are initially of no value to the builder.

The intricacies of modern brick production are described in detail in the video below.

The comment was sent successfully.