Saman: characteristics, manufacture and scope

The durability of the building depends on all the building materials used, without exception, but the wall material should be chosen most carefully, because even with an ideal site for construction, an unsuccessful choice of this component will lead to the building becoming dilapidated rather quickly. The material for the manufacture of walls can greatly affect the cost of implementing the entire project, in addition, some fundamental characteristics can depend on it - for example, the thermal conductivity of a structure. If we talk about proven classics, then perhaps there is no more practical material than adobe.

Characteristic

Saman is called a brick made of clay and straw with the addition of water, but exact proportions, as well as a complete set of components, do not exist - the composition of an artificial stone can differ significantly depending on what characteristics are required of it.

The main ingredient of any adobe was and is clay, preference is given to varieties with medium fat content. The viscosity of the mass can be different, therefore, if necessary, add a certain amount of water in order to make it easier to mix the composition. Traditionally, a filler was also used, which increased the strength of the dried clay, holding it together, and somewhat improved thermal conductivity. Historically, fibrous plants and even manure were used as such a component, but today finely chopped straw or chaff is often used as such a component.

Of course, the ingredients described above were all limited in the old days, but today, in the age of advanced technologies, the composition of adobe can contain various additives that significantly improve certain qualities of such a brick:

- crushed stone, sand or expanded clay crumbs in half with clay allow the drying building material to avoid strong shrinkage, while maintaining the specified dimensions and shape;

- casein and bone glue, as well as archaic slurry or modern liquid glass can be used instead of water to give uncured adobe blocks any desired shape without spreading;

- lime and cement are known for their ability to quickly release moisture into the environment, therefore they are added to the recipe so that the bricks dry faster and are moisture resistant;

- fibrous cellulose, chopped straw, wood chips or the same manure allow adobe to be also relatively elastic, which increases the resistance of the material to temperature extremes and compression or stretching.

Moreover, in some cases, more complex additives of synthetic origin are added - in particular, to increase the protection of building materials from the effects of living organisms. However, even in its classical form, adobe has enjoyed tremendous success for many thousands of years.

The exact date of the discovery of adobe is unknown, but scientists say that houses were built from it six thousand years ago. At that time, it was almost the only way out for the inhabitants of the steppe and desert zones, where even more traditional wood or natural stone were practically not found. As it happens in any era and in any state, building a house was also associated with huge costs, because the poor population had no choice but to come up with a way of building from what lies under their feet and no one really needs it.Ancient Egypt is considered the birthplace of the first adobe, and from there such material spread to many regions with the described climate conditions.

Modern adobe brick can have different characteristics, which strongly depend on its constituent components and their proportions, but on average, you should get something like this:

- density comparable to ordinary brick - at the level of 1500-1900 kg per cubic meter;

- thermal conductivity depends, first of all, on the amount of straw used (the more there is, the better the walls retain heat), but in general adobe is twice as good as a simple brick in this indicator - 0.1-0.4 W / (m * deg);

- in terms of resistance to compression, adobe blocks are very reminiscent of a modern foam block - in both cases, this indicator ranges from 10-50 kg per square centimeter.

Advantages and disadvantages

On the one hand, adobe has existed for several thousand years, but it not only has not lost its relevance, but even acquired it in those regions where previously wood reigned supreme as a building material. On the other hand, despite all the improvements in the composition and characteristics, such a block is not only not considered a leader in the building materials market, but can also be deliberately rejected as an option in favor of one or the other. All this indicates that adobe has its own advantages and disadvantages, which are worth considering even before the building material is purchased.

Positive properties.

- Saman has always belonged to the category of the cheapest building materials, and today, even with various additives, it remains almost the most affordable. Moreover, in many cases the owner can do it even on his own - this requires not so much money as simple knowledge and aspiration.

- According to its main characteristics, adobe will satisfy the majority of potential owners of the building, because it not only perfectly stores heat, but also has excellent soundproofing properties. Moreover, adobe walls also absorb excess moisture, participating in the normalization of the atmosphere in the house.

- Classic adobe is completely harmless - it is as natural a product as possible. At the same time, it, predictably, does not burn at all in a fire.

Disadvantages.

- An adobe wall requires careful plastering to protect it from moisture. By itself, such a brick has tremendous hygroscopicity, and this at least greatly increases the weight of the structure and can lead to its deformation.

- Adobe blocks dry quite quickly where they were invented - in hot countries, but in our conditions we have to wait a long time until the brick is completely dry and strong. Throughout this time, the building material should be carefully protected from moisture, and in general it requires special storage until the moment it is covered with a protective finish. Such exactingness leads to the fact that it is not always possible to build buildings from adobe, and in winter such a task looks completely unrealistic.

- Classic adobe, being 100% natural, does not pose any danger not only to humans, but also to domestic pests - from insects to rodents. Moreover, plant blotches can also attract such uninvited guests, and the voids remaining from them can be used by the latter as housing. In modern conditions, to prevent such phenomena, special chemical additives or the correct finish are used, but then such advantages of the material as environmental friendliness and partly cheapness are lost.

- Adobe masonry requires a certain amount of time for sufficient shrinkage to occur and the wall gaining strength. For this reason, the terms of erection of structures made of adobe always exceed those of the construction of a building made of bricks.

Views

The ingredients traditionally included in the adobe blocks can be used in different proportions and subject to different masonry technologies.For this reason, adobe is usually divided into two main varieties - the so-called light and heavy.

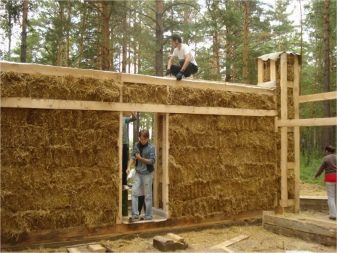

Although adobe is seen by most people as a brick or block of any other shape, the light variety is very rare. The fact is that for the manufacture of light adobe, a very small amount of clay is used - usually its share is no more than 10%, while the filler plays the main role. The resulting mass has significant fluidity and low plasticity, therefore, requires a more solid base from another material. Usually, light adobe is either a kind of covering for the lathing, which is installed next to the frame wall, or a filler between two such walls at once.

It turns out that it is impossible to build a house entirely from light adobe - it necessarily complements other building materials, but you can find advantages in this. So, the building retains all the advantages of its adobe counterparts (except, probably, cheapness), but it is erected much faster and somewhat easier. The disadvantages of this solution are that the material for the frame can cost significantly more than adobe blocks of a similar volume, and wood is often used as a crate with all its disadvantages in the form of price, combustibility, exposure to moisture and pests.

What is "ordinary" adobe blocks for most people is the so-called heavy adobe. We have already examined the composition of such a brick above, and the advantages of its use are obvious - the building turns out to be much stronger and more reliable, and you can start finishing almost immediately after the wall is erected, because adobe literally requires that it be protected from the atmosphere as soon as possible ... A huge disadvantage of this type of material is its susceptibility to the destructive effects of water - it is she who is the main enemy of adobe buildings. Although water is used in the production of adobe, it is always necessary to protect the finished material from moisture, from the drying stage to construction, decoration and living in the finished house.

Manufacturing technology

You can save a lot on the construction of an adobe house, given that you can make such a brick with your own hands at home from what literally lies under your feet. The main ingredient required is medium fat clay. Such a mass is quite well molded and does not allow water to pass through, therefore they usually look for it near water bodies or in marshy areas. A layer of the necessary material may not be located on the surface, but rather close to it - this is indicated by a high water level in the well or moisture-loving plants (mint, sedge) growing without watering away from water bodies.

If the clay is too oily, it can be slightly "improved" with sand - on average it should be added in a ratio of 1: 7. It is advisable not to use river sand because of the likely presence of silt in it, but large mountain varieties will do.

Due to the exactingness of the climate, it is necessary to harvest adobe in the warm season., however, clay is usually harvested much earlier - from the previous fall. The raw materials are dumped in a large hill (but not more than a meter in height) and covered with a thick layer of straw about 10 cm thick. In this form, the clay gets wet in the rains all autumn and winter and freezes, due to which it becomes plastic. With the onset of spring, the straw is removed, and the clay is covered with polyethylene, pressing the edges with stones - thanks to this, the heap will thaw faster, but will not give up all the moisture to the atmosphere, therefore a crust does not form on it.

As for the straw necessary for the production of blocks, it is suitable both fresh and last year. The only fundamental requirement is the quality of the raw materials - they should not have any damage due to improper storage.In some cases, you can do without this ingredient altogether, but then you need to replace it with any dry grass with strong fibers.

As we already understood, dry and warm weather is extremely important for the production of adobe and construction with its use, therefore the formation of blocks must begin with the first stable warming in order to have time to finish building the house by the onset of late autumn. For the production of adobe, it is advisable to choose a site near the planned construction - the finished blocks weigh a lot, therefore it will be problematic to carry them somewhere far away. To preserve the correct shape of the bricks, the site must be flat, and so that grass and debris do not stick to them, they are removed in advance. A drain for rainwater should also be provided - it is better if the area is slightly elevated above the immediate vicinity. The entire surface is covered with a straw cutter. It's okay, even if it sticks to the blocks, because it is still part of them.

Before kneading the clay, the site is additionally covered with a dense waterproof cloth. In the center of the improvised workshop, the prepared clay is poured in a heap, monitoring its uniformity without large lumps. A small hole is made in the center of the heap for water, it is poured into it as much as is required to give the mass of plasticity.

The easiest way to knead clay is with your feet - so significant efforts do not seem so energy-consuming. If you need to add sand to the mass to reduce the fat content, this is done already at the stage of mixing clay with water, while straw is added after the above ingredients are mixed. The straw is pre-soaked in water before being added to the mixture. Its proportions are usually about 15 kg per cubic meter of clay, although, as we have already mentioned, they depend on the needs and capabilities of the owner. The resulting mass must be kneaded with your feet until it becomes completely homogeneous. Be prepared that this will take a long time. The result is that very light adobe, which is raked into a heap and left for two to three days.

At this time, you should take care of the search or self-production of forms for blocks. They usually represent just a box without a bottom, a kind of "contour" for future bricks. It is better to decide on the size of the one who will plan and build the building, but this largely depends on the climate - massive blocks predictably take longer to dry, and where it is often cool and rainy even in summer, they should have the smallest possible size. Keep in mind that drying adobe is subject to shrinkage by 10-15%, and in some cases even more, so make blocks with a certain size margin. For greater convenience, the form for adobe is upholstered with polyethylene from the inside, and handles are attached to it from the outside.

The laying of future blocks is carried out on a flat area open to sunlight. The forms are installed on the ground, pre-leveled, cleaned and covered according to the described scheme, and the mixed and settled adobe is brought up in any way and poured into boxes, diligently ramming. Excess that does not fit into the mold is carefully removed using a board placed on opposite sides of the box, and then the mold is simply lifted, leaving the adobe in its place, and the procedure is repeated in the adjacent area.

Wet bricks need to be pierced in the center in two or three places with a wire about a millimeter thick, so that shrinkage during drying does not lead to a complete deformation of the block. To protect against precipitation, the molded pieces of mass are covered with waterproof materials - roofing felt or tarpaulin, which also contribute to uniform drying. In this form, the adobe is dried for 1.5 days, then it is turned on its side and given another day of time. Then you need to transfer it under a canopy, laying it out in the form of a well for final drying, which will drag on for another two weeks.At this stage, bricks are best placed on top of wood flooring or pallets to help drain excess moisture.

After that, it's time to construct a building from the finished blocks, but you can check if everything has been done correctly. If the technology is followed, adobe brick can withstand a fall from a height of two meters (at least to the ground) without any deformation. In addition, high-quality adobe is able to stay in shape after lying in water for two days.

Application

Although the adobe brick can withstand two days in water, such tests are very harmful for the durability of the house, because the masonry is carried out on top of a strip foundation with a height of at least half a meter, equipped with waterproofing from roofing material in several layers. The thickness of the tape should be at least 20 cm higher than the planned thickness of the masonry - this margin is intended for a thick protective layer of plaster or other finishing.

The recommended thickness of adobe walls is from 30 cm for internal partitions and from 50 cm for load-bearing ones. Even at the construction stage, adobe still continues to dry, therefore no more than two rows are laid per day. If necessary, the block can be cut with an ax. Laying is carried out on a mortar based on clay and sand.

Works are carried out only in dry and sunny weather, with the first signs of rain, work is urgently stopped and the walls are tightly covered with polyethylene. For finishing, any waterproof and vapor-permeable plaster is used, except for cement, which does not adhere well to clay. The finishing layer should be thick - at least 5 cm, you can even 10 cm. As jumpers over various openings, boards from 5 cm thick are used, which must have been treated with waterproofing compounds. The roof is, if possible, made hanging at least half a meter - this helps once again protect the adobe walls from precipitation.

For information on how to make an adobe block with your own hands, see the next video.

The comment was sent successfully.