Sanitary Silicone Sealant

Even non-rotting silicone is susceptible to mold attack, which becomes a problem in rooms with high humidity. Sanitary silicone sealant containing protective additives is produced especially for them. The use of such a sealant is wide, but there are limitations.

Peculiarities

In everyday life, sealants are used to adhere various surfaces, for example, ceramics, plastic, wood, glass and tiles, it can be used for grouting. Silicone sealants have excellent adhesion and water resistance. The material is flexible, easy to use and durable.

Sealants are multicomponent, when silicone hardens under the influence of a certain substance, and one-component, hardens with water by the action of air or moisture.

The latter are divided into several subspecies.

- Neutral Are universals that are used almost everywhere.

- Acidic - reliable, flexible, the most inexpensive in the line. They have a pronounced vinegar smell due to the acid they contain. They are aggressive to some materials, therefore they have a narrow application, often these are metals that are not subject to the negative effect of acid, ceramics, glass.

- Sanitary - contain special fungicidal additives, therefore it is used in rooms with high humidity and in plumbing. This subspecies is the most expensive.

Sanitary sealants can be used on internal and external insulation. They are not afraid of mold and moisture, do not rot. Despite its excellent adhesion, silicone does not adhere well to fluoroplastic, polyethylene and polycarbonate.

In order for the sanitary sealant to fulfill its task and please with the result, it is important to pay attention to the following points when buying:

- shelf life - the "old" sealant may peel off or not at all fasten the structural parts;

- plasticity - the parameter shows at what air temperature you can work with it, what is its elasticity, this is important when working outdoors at low temperatures;

- the quality of adhesion of a certain brand;

- shrinkage - shows how much the sealant will shrink when exposed to air and moisture. Normally, the silicone sealant should shrink no more than 2%.

Purpose, composition and properties

Sanitary sealant is universal, but due to the high cost, neutral is more often acquired.

Sanitary options are widely applicable for a variety of purposes:

- for plumbing works;

- when laying pipes;

- for processing joints and seams;

- for filling gaps;

- when installing kitchen equipment;

- for processing window frames;

- for grouting tiles;

- for insulation during electrical installation and repair work.

Sanitary sealants contain special additives that protect against mold and other organic deposits, such as those of a bacterial nature. They increase the cost of the material, but they are simply necessary in places with high humidity. Also, silicone products are quite resistant to chemical attack.

Because of these additives, sanitary sealants cannot be used in work involving food, drinking water and animals. This is the main difference from the universal remedy.

For example, they cannot repair dishes, food storage containers, drinking water containers, and seal aquariums. For this, it is better to use special, safe neutral sealants.

Sanitary silicone sealant has the following composition:

- silicone rubber - constitutes the bulk;

- hydrophobic filler;

- plasticizers for elasticity;

- a thixotropic agent that makes the material less viscous;

- fungicide that provides protection against fungus;

- primers that enhance adhesion;

- coloring pigment;

- catalyst.

A high-quality sealant is based on about 45% silicone rubber and the same amount of filler. The rest is made up of various additives, among which a fungicide must be indicated. Without antibacterial and antifungal additives, a sealant cannot be considered sanitary.

Thanks to the additives, silicone sealants are resistant to ultraviolet radiation, withstand frosts down to -30 ° C, have high elasticity, and are not afraid of temperature extremes and atmospheric precipitation. Therefore, they are excellent for outdoor renovation work, glazing of facades of buildings and greenhouses.

For home use, it is better to purchase sanitary sealants in small tubes. After opening the package, the tightness conditions are violated, and the remaining unused silicone will dry out over time or deteriorate its quality characteristics. If necessary, it is better to buy fresh. For large-scale repairs, for example, replacing pipes and plumbing in the bathroom, you can buy a larger tube, this will be more economical. For convenience, you will have to purchase a special pistol, which is characterized by reusable use, but cheap models quickly fail.

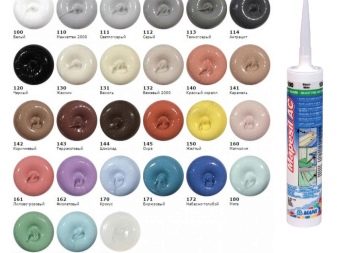

Color spectrum

Among sanitary sealants, white is more common. It is excellent for processing joints and seams when installing plumbing fixtures. Transparent sealant is also popular. Unlike white, its scope is wider due to its invisibility.

Manufacturers also produce gray and brown sealants. For example, for grouting joints or gluing pipes, so that the joints do not stand out much and do not attract too much attention. For insulation of electrical wiring, for example, when installing a roof, I use red and red-brown sealant.

The colored version is rare. The color of the material itself often depends on the filler, but a coloring pigment can also be added.

At home, it is impossible to add color to the finished sealant, this is done exclusively during production. Therefore, if a certain shade is required, you will have to spend time searching.

Which to choose?

A white silicone sanitary sealant can be used when installing a bathtub, sink and toilet. It will blend in with the plumbing and become almost invisible. For grouting ceramic tiles, you can use gray or brown silicone. This will make it look like a grout. For filling small cracks, bonding ceramics and wood, it is recommended to use a colorless silicone sealant. It is also used when installing windows and filling gaps between glass and frame. It will be conspicuous when processing pipe joints.

If you need to repair an old silicone suture without removing it completely, it is best to purchase a suture restorer. It is a special sanitary silicone sealant that can be applied over old joints.

The main thing is that the surface is pre-cleaned. The Joint Restorer must not be used over joints on window frames, bitumen and building materials that release solvents, oils or plasticizers.

Popular manufacturers and reviews

Choosing a silicone sealant, you can get confused. There is a fairly large selection of manufacturers' brands on store shelves. All promise excellent quality and durability, with a significant difference in price.

- "Herment Moment". This product has excellent sealing properties and is suitable for wide joints. The shelf life is 18 months. It is available in 85 ml tubes and 280 ml cartridges.Users note that the service life of the sealant is quite long, it is 2 years, after which it begins to darken. Of the shortcomings, it is worth noting a strong pungent smell, which makes you dizzy. Work should only be done in a mask and in a well-ventilated area. It has the strongest odor of any other brand of sanitary sealant. The sealant is very thick. To squeeze out with a pistol, you need to make an effort.

- "Bison". This is a good mid-price silicone sealant, frost-resistant. It is dyeable and comes in 280 ml cartridges. According to user reviews, it has a good viscous consistency, which is easy to squeeze out and evenly applied. But this sealant does not adhere well to damp surfaces, does not withstand constant contact with water, and therefore is not suitable for bathrooms, showers and external work.

- Tytan Professional 310 ml. This product has excellent adhesion, good water repellency, comes in 310 ml cartridges and has a shelf life of only 12 months. Blackening begins in 1.5-2 years after applying the seam. Users note a fairly tolerant odor, but not as strong as other brands of sealants. Positive feedback regarding the density: the product squeezes out perfectly and lays down. Among the shortcomings, one can note its high cost. It can be called the most expensive of the options presented.

- Ceresit CS 15. This option has excellent adhesion, sets quickly, seals well, and is inexpensive. There are marks on the spout to help you trim the tip. It comes in 280 ml cartridges. Curing of the product occurs due to interaction with humid air, therefore it cannot be used in completely enclosed spaces. It is not recommended for filling joints completely in water, and is also subject to mechanical stress and abrasion. This sealant has poor contact with bitumen and materials based on it, natural rubber, ethylene propylene and chloroprene rubber. It guarantees excellent adhesion to glass, ceramics and enamelled surfaces. The sealant hardens quickly, but may stick fingers together. Users are noted for a long lifespan - it does not turn black for more than two years.

- Krass. This product is characterized by good water resistance and plasticity, excellent adhesion to the surface, easy to apply and remove from hands, does not turn yellow over time. The smell is not strong and disappears quickly. Suitable for glossy and porous surfaces. The price is inexpensive. Of the shortcomings, users note its fragility. Sanitary sealant begins to crack and turn black in six months or a year. It can only be applied on a dry surface. It is suitable exclusively for interior work.

If you make your own rating based on user reviews, then Ceresit CS 15 will take the first place in terms of its quality properties, durability of seams and price. Tytan Professional 310 ml is inferior to him exclusively in price. In third place, you can put "Herment Moment", which also differs in its characteristics, but due to its density it is difficult to apply seams.

Recommendations for use

In order for the sanitary sealant to adhere well and not flake off over time, it must be applied correctly, following the instructions on the package. It can be tested before use. To do this, you need to apply a little silicone to a piece of plastic and allow it to completely cure. If the seam comes off completely with ease, then the sealant is either expired or of poor quality. If it comes off with difficulty or in pieces, then you can safely use it.

There are several steps to follow to apply the sealant.

- It is necessary to remove the old sealant layer, if any, to clean it if necessary. The surface must be dry and clean for the best adhesion. Degrease. The instructions for use on some cartridges, on the contrary, advise slightly moistening.

- To make the seam even and neat, glue masking tape on the sides.

- Insert the cartridge into the gun, cutting off the tip at a 45 degree angle. The thickness of the sealant extruded depends on how far the tip is cut from the edge.

- Apply sealant. To keep the seam of the same thickness, press the gun trigger with equal force. You can smooth and smooth the seam with a rubber spatula, a damp cloth or a soapy finger. If a film has formed, you can no longer touch it.

- After laying the seam, immediately tear off the tape. You can remove excess or the consequences of inaccurate application by rubbing with the rough side of a sponge, a rag or a rubber spatula. The sealant must be wiped off immediately, after hardening it will be very difficult to do this.

The first film appears within 10-30 minutes. The full cure time depends on the type of sanitary sealant. Acid versions harden in 4–8 hours, neutral ones - about a day. The hardening time is influenced by the amount of additives and dyes, the more there are, the longer it hardens, the thickness of the joint, the temperature and the humidity of the air. On average, the sealant hardens completely in a day, with external work - up to one week.

If drying time matters, then the process can be artificially accelerated:

- improve ventilation;

- increase the air temperature, the sealant will dry 1.5-2 times faster;

- sprinkle the frozen film with water from a spray bottle.

The composition of silicone sanitary sealant may differ from different manufacturers, as well as the conditions of use, so when using it, it is important to read the instructions on the package.

For information on how to properly use silicone sealant, see the next video.

The comment was sent successfully.