Anaerobic sealant: pros and cons

The term "anaerobic" is borrowed from microbiology by the construction industry. It denotes a class of microorganisms that do not need oxygen to function. Accordingly, the essence of the work of the sealant can also be characterized - for polymerization and hardening, it does not need air, because all these processes take place without the participation of oxygen.

Peculiarities

There are different types of sealant for different work complexity.

They differ from each other in several ways:

- viscosity;

- fluidity;

- the degree of penetration into the surface.

The agents themselves may be designed to seal a thread, fitting, flange, or bushing. To accurately determine the scope of use of the composition, you should study the table that is located on the package.

Based on the degree of strength, all compositions can be divided into:

- Standard - are used for materials that are not exposed to vibration in the absence of the need for frequent dismantling or disassembly of elements. Such sealants are much easier to remove without the use of special tools. The value is in the range of 4 - 9 Nm.

- Average - used for joints that are exposed to high atmospheric pressure or strong vibration during service and repair work. Removal of such a substance requires special tools or direct heating with fire. The value is 15 - 22 Nm.

- Elevated - mainly used for fixing threaded connections that will not be dismantled or disconnected for several years. This grade is the most durable and can withstand very powerful vibration and pressure. In order to disconnect such a connection, a force of at least 55 - 60 Nm is required.

The less space between the elements to be joined, the higher the penetrating property of the adhesive should be. Accordingly, the consistency of the composition and its viscosity should be minimal.

The color of the sealant indicates the scope of its use and some of the properties of the composition. At the moment, you can buy glue in blue, green, red, orange and yellow.

Also, the compositions are divided into the following groups:

- Used in the communications of heating systems to seal pipe elements. They differ in that they perfectly tolerate high temperatures and hot water.

- Hermetic compounds, immune to the influence of substances with an aggressive environment. Withstand temperatures in the range of 60 - 150 ° C.

- Fast hardening adhesive with improved adhesive properties.

Properties

All the positive qualities of an anaerobic sealant are achieved through a chemical reaction between the substances that make up it. It consists of oligomers or polymers from the acrylic group (giving the required consistency and viscosity) + initiation substance (providing accelerated polymerization).

Getting on a metal surface, the mixture fills even the smallest and most insignificant cracks, and after that, quickly solidifying, forms a kind of rubber layer. Under this layer, the polymerization process takes place with the help of radicals. The sealant hardens gradually, starting from the moment oxygen ceases to flow to the seam. One of the main advantages of such a sealant is its high vibration resistance, which prevents the thread from loosening its fixation.

Using many years of experience in the construction industry, manufacturers have managed to create a material that has a number of undeniable advantages:

- reliable fixation of plumbing pipes;

- high strength and wear resistance;

- resistance to vibration vibrations, which are often the underlying reason for the destruction of communications;

- safe in contact with drinking water;

- after the glue hardens, it is no longer possible to dissolve it in water;

- connection of materials of different structure;

- ease of use - even a person without any experience can handle the application;

- resistance to high atmospheric pressure - no more than 50 atmospheres;

- immunity to aggressive substances, solvents, paints and oils;

- protects metal from corrosive changes;

- long service life, which even in the worst conditions lasts up to 4 years;

- high temperature compound that does not degrade even at temperatures of + 300 ° C.

However, not everything is perfect here either. Having a wide range of advantages, the sealant still has some disadvantages:

- The communications fixed by this composition are very difficult to disconnect or dismantle. Sometimes, to remove the sealant, it must be heated with direct fire. In contrast, an ordinary fum-tape or tow will be cleaned much easier.

- High cost price. Quite often, consumers refuse to buy an anaerobic sealant due to its high price. But if we take into account the sufficient economy of consumption of the composition, then the funds spent will be justified

- The sealant from different manufacturers will not be identical, their composition will differ in the volume of the active component.

You need to work with the sealant strictly following the instructions. Do not handle wet joints, as the desired effect cannot be achieved. Therefore, it is important to completely dry the work surface and remove all moisture. There is also a limitation in the diameter of the processed communications - pipes should be no more than 10 cm in diameter, wider parts are more difficult to process and take longer to dry.

Scope of application

Oxygen-free sealant adhesives are widely used in various fields:

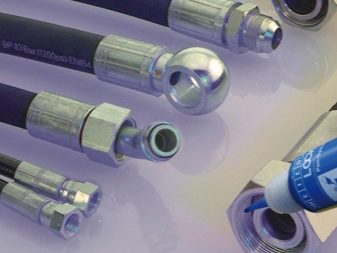

- For locking and sealing threads, replacing various mechanical devices. At the moment, the composition is the simplest and most reliable way to strengthen threaded connections against the effects of shock, shock and vibration. Due to its semi-liquid consistency, it completely fills the entire space and is able to evenly distribute the load along the turns, preventing the leakage of gaseous substances or any liquid.

- For blocking and securing sliding joints. This includes all metal connections such as bushings and bearings. Oxygen-free gels allow parts to be seated with a gap, without heavy deforming stress, while maintaining ultimate shear strength.

- Reinforcement of various pipe connections: flanged and threaded. Unlike mechanical devices, which are destroyed over time by vibration and stress, decompose in an aggressive environment and pollute the surrounding space, the sealant is able to remain in its original state for a long time and firmly fix the pipe elements.

- Impregnation of porous material, welded seams and pressed products. The gel perfectly removes small pores, cracks and other defects in the field of welding, casting and pressing.

How to use?

As mentioned earlier, the anaerobic sealant cures very quickly. However, despite this, it is not difficult to work with it and even a beginner can cope with it. To achieve the desired effect, you just need to follow the instructions on the rules for using the product, because the sealant is sold ready-to-use and does not need to be pre-prepared or mixed with solvents. It is better to completely clean the working surface in advance, and then degrease it - this will strengthen the reaction and the composition will set much better.

Instructions for use:

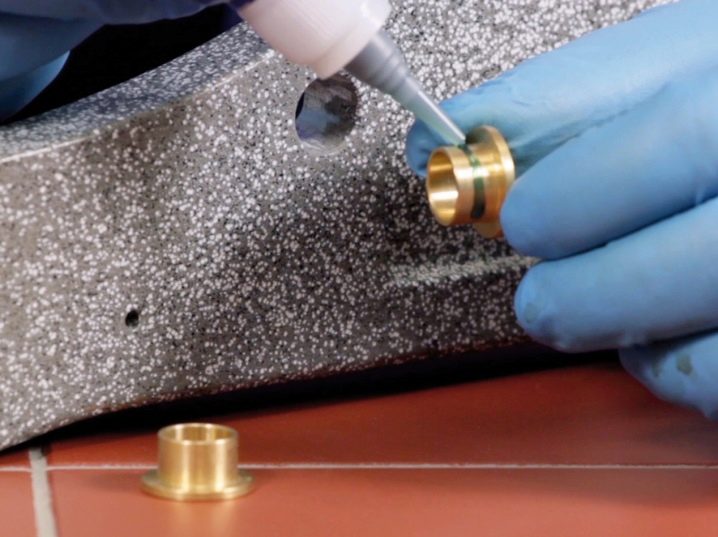

- We take the container with the composition and shake thoroughly, thereby mixing the contents.

- We open the container and apply the product around the perimeter of the connection.

- Next, we completely screw in the elements to which the sealant was applied.

- The excess must be removed immediately, without waiting for the composition to dry.

- Let the sealant dry, leaving it for about half an hour (the gel dries in different ways, depending on the diameter of the compound being processed and the temperature in the room) and then check it under a pressure of 10 atmospheres. If the ambient air temperature does not reach + 15 ° C, the sealant must be heated. If after checking there are no leaks, then a day later you can carry out a performance test under a pressure of 40 atmospheres.

For maximum bonding, the compound can be applied to both surfaces, i.e. inside and outside. But this must be done carefully so as not to apply too much sealant. If plastic pipes are processed, then before work they must be treated with a special activating agent. Quite often, a brush is included with the container, which greatly simplifies the application process.

Manufacturers and reviews

Anaerobic sealant is produced and produced by quite a few companies, so some difficulties may arise when buying from a consumer. Some of the most common and popular brands of anaerobic sealant are rated:

- Loctite. The firm produces both liquid sealants and sealing threads. They prevent leakage of gas or liquid and greatly increase the strength of the joint. The price of the formulations of this brand depends on the area in which they are used and what characteristics the gel has. For example, the universal sealant Loctite 577 costs 1,760 rubles for 50 ml, while Loctite 542, designed for small threads, costs slightly more than 1,800 rubles for the same volume.

- "Catch No. 3" - a medium-strength anaerobic sealant with a homogeneous thixotropic consistency and a blue color without any inclusions. The adhesive is resistant to substances such as water, oil derivatives, gas, hydraulic fluid, ethylene glycol compounds, alkaline and acid solutions. It is used in work with any metals, regardless of the presence of a protective coating. Examples of application: valve mechanisms, covers, attachments of internal combustion engines, sealing of necks, assembly of utilities communications (heating, gas supply, water supply), plumbing. It tolerates high pressure and vibration well. The cost is 300 rubles. Analog from Loctite under number 243.

- SantechMaster. The domestic company produces a red and blue composition in the form of a gel, which comes with a brush. It is mainly used in work with gas and water connections up to 5 cm. In a room with room temperature (18-19 ° C), the assembled line can be tested already 15 minutes after assembly under a pressure of 0.5 atmospheres. After 60 minutes it can be increased to 10 atmospheres, and in a day up to 40. The sealant is unstable to antifreeze, gasoline, alcohol, high pressure and temperature. A bottle with about 15 ml of material will cost at least 150-200 rubles.

- "Siseal" - sealant from the Manta Ecologica company. It is also most often used in fortifications of engineering systems: plumbing, gas and water. Let's work with drinking water. The curing time also depends on the room temperature. It is a medium-strength adhesive, but the product with the prefix "S" (red) is already a strong sealant, which needs to be heated with a hairdryer or torch for disassembly. When disassembling, it does not require additional heating. Basically, all other characteristics are standard. The cost of a bottle of 100 ml is about 800 rubles.

- Permatex. Sealants from this company are designed primarily for the flange, ensuring the filling of the smallest roughness and absolute contact between the mating surfaces.After tightening the bolts, the compound will displace all the air and turn into a plastic, characterized by high strength. As mentioned above, glue is most often used for flange connections of the gearbox, sediment, in the cylinder block and seals small gaps between metal elements. The use of the mixture will increase the torque indicator, replace the additional tightening of the fasteners, protect against corrosion, and make further dismantling easier. It also distributes the load evenly over the entire surface area and makes the transfer of forces between parts more accurate, protects against dirt and simplifies the process of installing shims on vertical surfaces. A bottle of 50 ml will cost the consumer about 700 rubles.

- Quickseal 728 - Medium strength oxygen-free gel adhesive. Used for fastening connections of hydraulic and pneumatic power mechanisms. The sealing compound seals the threads of metal parts, protecting them from mechanical damage and vibration waves. Requires heating when removed. Features of polymerization: the glue hardens in a temperature range of + 20-25 ° C, and the lower the temperature in the room, the slower the sealant will harden. The material is not used for reinforced plastic elements, oxygen equipment and systems or compounds with strong oxidation. Designed exclusively for standard metal structures. Before work, the surface must be cleaned and degreased. The cost of the bottle is 800 rubles.

Tips & Tricks

If it becomes necessary to separate the fixed parts, the sealant can be removed immediately after work or some time after hardening. For dismantling, you will need an adjustable wrench and a hair dryer if the composition is strong.

Removal instructions:

- we turn on the construction hair dryer and direct a hot stream of air to the seam;

- wait until the mass begins to crumble and then remove it with an ordinary rag;

- with an adjustable wrench and disassemble the connection.

There is no need to completely clean off the residue, a new layer can be applied directly over the old one.

When choosing a sealant, consider the following:

- operating conditions of the connection;

- any thread features;

- at what temperature the gel will be used;

- what are the requirements for the strength of the future connection;

- how often it will be necessary to disassemble the connections;

- what material the thread is made of.

For the pros and cons of anaerobic sealant, see the following video.

The comment was sent successfully.