Sealant "Stiz-A": color, composition and other characteristics

When working with metal-plastic parts of windows, stained-glass windows, balconies, a special tool is required to securely fasten the joints. An excellent choice is the Stiz-A sealant. It is a popular, no pre-dilution formulation, ready to go straight out of the box. The positive technical characteristics of the product prove that it is the best among similar materials.

Peculiarities

Means "Stiz-A" is recognized as one of the best means for isolation, produced by a domestic manufacturer - the Russian company SAZI, which has been a supplier of these products for about 20 years and is well known to experienced builders for the high quality of its materials.

"Stiz-A" is a one-component, strong and durable material based on acrylic.

It is a viscous, thick paste that hardens during polymerization, remaining extremely elastic, and at the same time optimally strong. The acrylate mixture, which includes different types of polymer compounds, has high protective properties.

In most cases, a white material is used for double-glazed windows, but it is also available in dark and light gray, brown and other colors required by the customer.

A feature of the sealant is its high adhesion to polymer surfaces, that is why it is in demand when erecting plastic windows. In addition, it can be used to seal any street seams - cracks and voids in metal, concrete and wood structures. "Stiz-A" is specially designed to strengthen the outer layers of assembly joints. In addition, the product contains antibacterial substances that prevent the appearance of fungus.

The products are produced in packages of 310 and 600 ml, for large-scale works it is more profitable to immediately purchase the composition packaged in plastic buckets of 3 and 7 kg.

Dignity

The advantages of the products are:

- strict compliance with GOST 30971;

- resistance to direct sunlight;

- high vapor permeability;

- immunity to high humidity;

- high degree of plasticity;

- rapid formation of the primary film (within two hours);

- small shrinkage during operation - only 20%;

- frost resistance and heat resistance of the material, it can withstand temperatures from -60 to +80 degrees;

- optimal adhesion to most working surfaces, including plaster, vinyl chloride polymers, wood, brick, metal, concrete, artificial and natural stone, and other materials;

- the possibility of staining after complete hardening;

- adhesion even to wet surfaces;

- resistance to mechanical deformation;

- the service life of the product is at least 20 years.

disadvantages

Among the disadvantages of these products, one can single out a short storage time - with the integrity of the package from 6 to 12 months. A relative disadvantage is its elasticity, which is slightly lower than that of silicone sealants.

Acrylic composition is rarely used for interior work due to its porous structure., which over time begins to absorb various fumes, and then its layer can darken and look sloppy. But if you paint it after hardening, you can avoid such a problem.

Application rules

When using a vapor-permeable acrylic sealant, you should know how to properly seal the cracks with it. Application is carried out with already installed PVC slopes.For work, you will need a basin of water, construction tape, a knife, spatula, sponge, rags or napkins. If the material is packed in a special bag (cartridge), then an assembly gun is needed.

Procedure:

- preparation of the coating provides for cutting of the polyurethane foam, its surface should be smooth, not have breaks and strong porosity (pore size up to 6 mm in diameter is allowed);

- the surface next to the foam is thoroughly cleaned of dirt and dust, sometimes it makes sense to use tape, at the end it is wiped with a damp cloth;

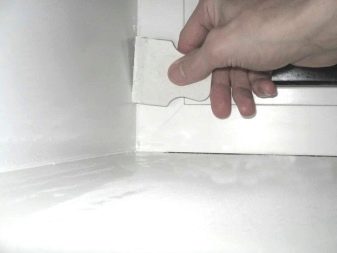

- masking tape can be used to paste over the areas adjacent to the gap, taking into account that the sealant will cover about 3 mm of the window frame and walls;

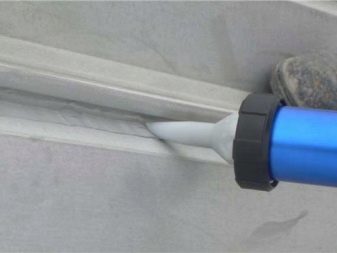

- the paste is squeezed out with a pistol into the cracks, while it is necessary to simultaneously smooth the seam, the layer thickness is from 3.5 to 5.5 mm, leveling can also be done with a spatula;

- the protruding layer is smoothed with a finger, wetting it in water, all the recesses must be filled to the end, the excess composition is removed with a wet sponge, trying not to deform the product layer;

- then the tape is removed, and after hardening, the seams are painted to match the walls or window frames.

Qualified craftsmen advise to carry out work in small areas., which can be processed immediately, because during polymerization it will already be difficult to correct errors.

If a sealant has already been used, it is important to scrupulously clean the entire surface of it. If this is not done, in the future you may encounter traces of the sealant in the form of stains that spoil the appearance of the plastic.

Acetone must not be used to degrease coatings, which leaves streaks and unsightly stains. You can use gasoline or white spirit.

It is possible to apply "Stiz-A" either with a pistol, or with a brush or a spatula at temperatures from +25 to +35 degrees, complete drying takes place in 48 hours. Material consumption per one running meter is 120 grams.

Nuances of work

In order to maximally protect the seams from the penetration of cold, moisture and make them super strong, a certain thickness of the sealant is important - 3.5 mm. Since this is difficult to regulate, you should use a regular ruler with markings at the end. To do this, it is immersed in a layer of foam. You can determine the size of the layer by the remaining traces. After that, the damaged coating is additionally smoothed with a paste until it is completely leveled. It should be noted that a smaller layer has a reduced quality, which affects the strength of the insulation.

Builders often use two sealants - "Stiz-A" and "Stiz-V", this also makes a certain sense. This is explained by the fact that for absolute security it is necessary to have both a reliable outer layer of an insulating substance and an inner one, which is provided by "Stiz-V". Unlike the A-grade sealant, due to which moisture in the foam is discharged outside, the B-grade sealant prevents steam and moisture from entering the room.

On the other hand, "Stiz-V" is not intended for outdoor use. - as a result of application, the liquid entering the polyurethane foam accumulates in the seam, in addition, the thermal insulation properties of the construction foam are reduced. That is why Stiz-A is considered an ideal insulation tool for external joints.

According to the builders, with a large scope of work, it is wiser to use formulations with packaging in a polymer tube or file package, since the increased cost is compensated by the speed of sealing with a pistol.

To learn how to install a window using a vapor-permeable sealant "Stiz-A", see the video below.

The comment was sent successfully.