Sealant "Sazilast": properties and characteristics

Sazilast is a two-component sealant that is effective for a long period of time - up to 15 years. It can be used for almost all building materials. Most often used for sealing joints on roofs, joints on walls and ceilings. The required time for the solidification of the substance is two days.

Peculiarities

Sazilast sealant is universal and has excellent technical characteristics.

The peculiarity of this protective coating is that it can be applied to a damp surface.

The main technical characteristics are as follows:

- has low vapor and air tightness;

- application at low temperatures is possible;

- the product is resistant to diffusion influences;

- interacts very well with materials: concrete, aluminum, wood, polyvinyl chloride, brick and natural stone;

- interacts well with paint;

- application to the surface is allowed with an allowable deformation rate of at least 15%.

Varieties

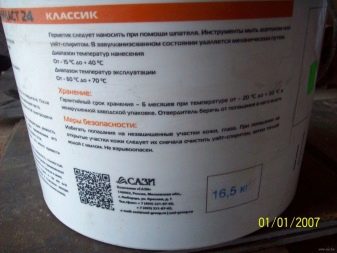

There is a wide variety of packaging for sealant. The most popular are plastic buckets weighing 15 kg.

Depending on the type of application, 2 groups are distinguished:

- for foundation installation;

- for the repair of building facades.

To repair the foundation, use "Sazilast" -51, 52 and 53. They are made of a two-component composition, namely a hardener based on a polyurethane prepolymer and a base paste based on polyol.

Resistant to ultraviolet radiation / compositions 51 and 52 /, therefore it is recommended for use for roofing work. When processing in hard-to-reach places, the composition - 52 is mainly used, since it has a more fluid consistency. For work with high humidity, the best option is the seal 53, since it is especially resistant to prolonged exposure to water.

All sealants show excellent protective properties, they reliably resist the effects of:

- water;

- acids;

- alkalis.

Sazilast -11, 21, 22, 24 and 25 are used to repair the facade of buildings, residential premises and not only. seam layer. Type 21, 22 and 24 two-piece polysulfide seals are not intended for residential use. Sealant No. 25 is a polyurethane-based sealant characterized by quick readiness for use, since it does not depend on the parameter of the joint and external temperature parameters of the environment. It can also be stained with paints and various substances.

It is used for planes with a surface curvature of up to 25%, as well as seals 22 and 24. The uniqueness of sealant 25 manifests itself in the possibility of using about 50% for an irregular surface. All types of "Sazilast" are highly durable and resistant to temperature extremes.

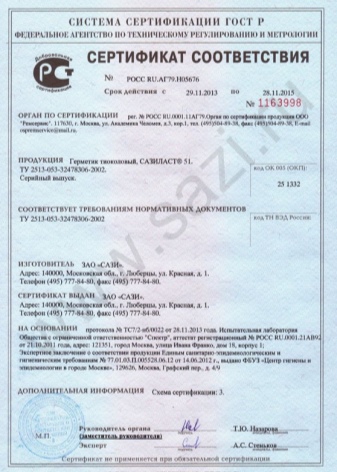

The product has an international quality certificate, which increases its status and guarantees good demand.

Recommendations

To apply the sealant during repair activities, the following tools are required:

- low-speed drill with a paddle attachment;

- spatulas;

- masking tape.

It is important for safe operation to thoroughly clean the surface of the structure. The protective layer is applied to a dry or damp surface.For a neat and aesthetic appearance of the expansion joint, mounting tape is glued to the edges of the finishing material.

Appropriate to use subject to:

- the right proportions;

- temperature regime.

You need to follow this recommendation: do not use a large amount of hardener. Otherwise, the protective coating will quickly harden, which will give the structure insufficient strength. If there is not enough hardener, then the composition will have a sticky consistency that does not meet the necessary requirements.

When applying a protective one-component sealant 11, it is not allowed to overlay the surface with a moisture content of more than 90%, as well as its contact with water. The addition of a solvent is strictly prohibited, since the characteristics of the composition will change, without them reliable installation will be impossible. For compositions 51, 52 and 53, it is recommended to apply the material to the surface at an ambient temperature of -15 to + 40 degrees C. The layer should be less than 3 mm; if the joint width is more than 40 mm, then the area should be sealed in two approaches. Apply to the substance around the edges, then pour over the joint.

Safety engineering

It is very important not only to reliably and accurately perform the installation of deformed joints, seams, but also to comply with safety requirements. To do this, you need to follow the prescribed rules. Do not allow the sealant to come into contact with the skin, if this happens, then it is necessary to promptly rinse the area with water using a soap solution.

The basic rule for all protective coatings is to prevent moisture from entering. For protective coatings 21, 22, 24 and 25, the warranty period is 6 months at temperatures from -20 to +30 degrees C. Protective sample 11 is also stored for 6 months, but if the temperature is not lower than +13 degrees C, during storage not lower -20 degrees C retains its properties for 30 days.

Two-component polysulfide sealants 51, 52 and 53 are kept at temperatures from -40 to +30 degrees C for 6 months.

Life time

Protective coatings 21, 22 and 23 are usable for 10 to 15 years. With a layer thickness of 3 mm and a joint deformation of up to 25% adhesive mixture 21, 22, 24 and 25, the time limit from the start of operation is 18-19 years.

See the following video about Sazilast sealant.

The comment was sent successfully.