Sealants for heating radiators: types and features of choice

Every heating system, regardless of quality, one day breaks down and needs to be repaired. One of the most common reasons for its failure is depressurization, which leads to leaks. To eliminate such defects, a special material for heating communications, called a sealant, is popular.

Requirements

A material such as a sealant is needed not only to eliminate leaks on installed systems. It is used for assembly after purchase or bulkhead sections, or for repairs. Such a substance ensures the tightness of the joints of all joints. It is resistant to high temperatures and the tightness will not be broken at high heating temperatures.

There are many types of sealants commercially available in the markets these days. All of them can be used for a separate purpose. And this can mean only one thing, that choosing a suitable type for heating is significantly complicated. If you do not want to be mistaken when choosing the type of substance, then you should study the basic requirements for a sealant for heating.

An insulator that will be used to seal joints or to eliminate leaks on heating systems, must meet the following requirements:

- It must have a high resistance to high temperatures.

- Also resistant to possible deformation-type loads.

- They are not afraid of exposure to moisture and easily transfer it.

- And it is obliged to withstand possible temperature changes in the system.

It is a material with such compliance to the requirements that is the ideal option for eliminating leaks and sealing the system.

Varieties

Sealants are divided into varieties according to the scope of application, since they have different compositions.

They are of the following types:

- For outdoor use, it is applied to the place of the leak and after it hardens, the leak is eliminated, and the heating system becomes hermetically sealed again.

- For internal use, most often in liquid form, they are poured into the system, and he finds the place of the defect under pressure and eliminates it from the inside.

- A sealing type, which is used to strengthen the joints of the system and thus achieve tightness.

The type of sealant is produced depending on the degree of damage, on the availability of the damage site for repair work.

Sealants for outdoor use are available with one component or two. And since the liquid in the system can be not only hot, but also under pressure, it is necessary to eliminate the leakage with high quality. The outdoor sealant must be resistant to high temperatures. Such an index can be read on the packaging of the substance.

Also, sealants are divided into components.

Sealants based on such substances are popular:

- silicone;

- acrylic glue;

- rubber and aerobes.

For such purposes, it is not recommended to use an external sealant in the base., which is acrylic, as it is used and intended for use on cold water systems. And acrylic glue is not suitable for heating systems or hot water supply. And it is not suitable for the reason that after applying it to the surface, it turns to stone and, therefore, is not plastic and begins to collapse when the temperature rises.

For heating and hot water systems, an exterior sealant based on silicone or rubber is ideal.

Such compositions can be of different types of silicone, but for the heating system it is recommended to use a sealant with neutral types of silicone. And if a silicone sealant with acids is used, then after it hardens, it will begin to react with the metal.

If this material fully meets all the necessary requirements, then it is still better to use it with the use of additional hermetic means. Basically, such sealants are made for filling cracks and holes. And if the packaging indicates a different area of use, but it fits all the requirements for the heating system, then it can also be used for the system.

For example, the type of sealant that is designed to seal car engines is ideal for sealing heating.

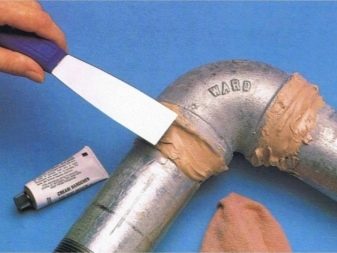

When applying a composition of the required type to the place of leakage, it is recommended to use a special reinforcing mesh.

How to choose?

It is important not just to choose a sealant for the radiator, but heat-resistant options to eliminate the leak. If you notice that a joint is leaking somewhere near the batteries, you need to decide which sealant will help, and reviews can help in this matter.

The choice of sealant is carried out, starting from the tasks that he must solve to eliminate a leak in the heating system. If it will be used to seal the joints of the heating system, then paste-type silicone sealant is perfect for these cases.

It can be dry or non-dry.

Differences between sealants can be as follows:

- Drying compounds. After the composition applied to the surface dries, it has the ability to shrink, but this happens if the drying technology is violated. So, deformation of the composition may occur, cracks and drips will appear.

- Non-drying formulations. Ideal for removing small cracks and can also be used to seal heating system connections. But such compounds can be squeezed out if the pressure in the system exceeds the normal value.

Aerobic compounds, which are considered a type of acrylic sealant, are used in some situations to repair heating defects and leaks. This type of sealant is able to withstand temperature changes, is resistant to mechanical stress and is resistant to alkali and acid solutions. If it is applied to the site of the defect, then it quickly fills the flaw and dries up.

It can be used to seal the threaded connection of the heating system, but if one or another section of radiators is subsequently dismantled, it will be difficult.

Application

Everyone understands that if the heating system is of a hidden type and is located behind the finishing layer, then in the event of a leak, it is not always possible to use a sealant for external use. For such cases, an internal sealant was invented, which must be poured into the heating pipeline system.

There are situations that unexpectedly there is a leak in the heating system, and it needs to be fixed in a short period of time, but there is no sealant with suitable characteristics at hand. Automotive sealant can be used in this situation. Or a sealant for car radiators.

But in order to apply it to the surface, you need to carry out preparatory work. They include the choice of the composition, and it is performed based on the type of use of the coolant. If you choose an inappropriate composition, then this can lead to blockage of pipes in some places.

Nowadays, internal sealants are divided into the following types at the place of use:

- Compositions for heating systems in which the heat carrier is water or antifreeze.

- Mixtures for sealing joints of the heating system.

- Funds for boilers that run on solid fuels or gas.

Compositions of a German manufacturer are popular among liquid sealants today. Such a composition performs high-quality sealing of the heating system and does not affect the heating boiler in any way.

In order to use a liquid sealant for internal use, it is necessary to determine the appropriate concentration of the composition, since the stopping and elimination of the leak depends on this. In the event that about 80 liters of liquid have flowed out of the system during the day, then 1 liter of the mixture is enough to qualitatively eliminate the cause.

In order to determine the total volume of the coolant in the entire system, it is necessary to calculate the footage of all pipes and their diameter, but you can do otherwise. Just drain the liquid into a container of which you know the volume.

In order to eliminate possible system leaks during heating operation, liquid sealant must be poured into the system regularly. So, your system will not fail, but if the expansion tank leaks, you will not be able to eliminate the defect in this way.

To use the composition in the heating pipeline, you must first bleed the air from the system. If this is not done, then under high pressure the sealant will begin to clog not only the leak, but can also stop the circulation of the coolant in certain areas.

In order for the sealant to circulate freely through the system, it is necessary to open all the taps. In the first radiator, the tap must be unscrewed altogether. After the process has passed, it is necessary to install the pump, and warm up the system to 60 degrees and pump up a pressure of 2 bar.

It is important not to forget to remove all mechanical cleaning filters before pouring liquid sealant, if this is not done, the sealant will disable them.

The very filling of the composition should take place according to the scheme:

- We collect 1.5 buckets of heated liquid, shake up the composition of the sealant and add it to the buckets and quickly pump it into the system.

- Next, we remove all air from the heating system and the solution will begin to circulate through the system.

It takes about 3 days to seal all damaged areas. After that, you need to pressurize the system and make sure the quality of the seal.

For information on how to eliminate a heating system leak with a sealant, see the next video.

The comment was sent successfully.