How to dissolve silicone sealant?

Silicone-based sealants are widely used in finishing works, for grouting tiles and sanitary equipment. In certain cases, it may be necessary to dilute the mixture to a liquid state for subsequent disposal. How to dissolve silicone sealant, it will be useful to know every person who starts repairs with their own hands.

Material features

The silicone based sealant has excellent technical characteristics, which is why it is so often used in finishing works.

Let's consider the main characteristics and features of the material in more detail.

- Resistant to moisture. A silicone based sealant is almost indispensable in the bathroom.

- The mixture adheres perfectly to almost any material and reliably fills gaps and seams.

- Resistant to temperature extremes. It is also worth noting that the mixture can withstand exposure to both very high and low temperatures and can be operated at a mode from -50 to +200 degrees.

- Good elasticity. Thanks to this quality, the sealant does not crack when it dries. In addition, the mixture can be applied to areas that are prone to deformation.

- Most types of silicone sealant contain fungicides, which are antiseptic. Thanks to this component, the mixture prevents the appearance and spread of microorganisms.

- High strength.

The discussed advantages of the sealant composition can present certain difficulties when it comes to removing the sealant. It is impossible to completely remove the hardened layer of the mixture using the mechanical method. In order to clean the coating well, it is necessary to resort to chemicals that will soften or dissolve the sealant.

Types of solvents

When choosing one or another agent for diluting the hardened sealant, it is important to take into account some of the features of its composition.

Silicone based blends are classified into three main groups.

- Acid-based. Acetic acid is used in the manufacture of this type of silicone solution. Such material has a low price and not a very pleasant smell. The composition is incompatible with some metals and marble.

- Alkali-based. This type of mixture is made on the basis of amines and, as a rule, has a specific purpose.

- Neutral. They are considered universal formulations that are suitable for almost all materials.

On the modern building materials market, you can find special impregnations for diluting the sealant. However, folk remedies are no less effective and will help in a situation when there was no special purpose composition at hand.

Improvised means

The use of folk remedies for diluting the sealing composition is convenient primarily because there are dissolving mixtures in almost every home. If it becomes necessary to wash off the not yet cured sealant, you can use plain water and a rag. This method is suitable only when more than twenty minutes have not passed since the application of the mixture.

Minor traces of sealant can be removed with gasoline or kerosene.Silicone mixtures can also be acted upon with acetone or acetone-containing solutions.

Special formulations

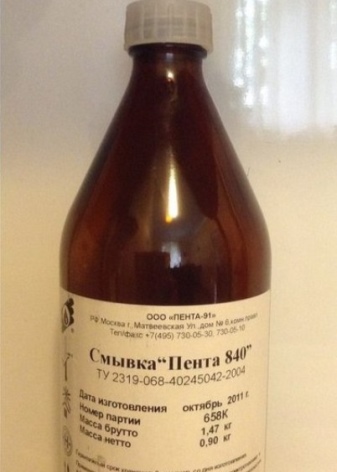

One of the popular means for thinning silicone sealant is "Penta-840"... This solution is suitable for application to almost any surface. The disadvantage of the mixture is its high cost.

The process of diluting silicone sealant at home with the composition "Penta-840" pretty simple. It is necessary to apply the solution to the area that needs to be cleaned and left for the time indicated on the product packaging. Then the softened silicone is easily cleaned off the surface.

A cleaner can be used to soften fresh sealant. Quilosa limpiador... The product is suitable for all types of hard surfaces.

Means Permaloid Ideal for removing cured sealing layers from plastics. It does not dissolve plastic and does not leave any marks on the material. The cleaner is also used to clean metal surfaces and car parts.

Purifier Dow Corning OS-2 intended for cleaning surfaces before further processing with paints and varnishes, sealants or glue. The product is safe for human health and can be used to clean surfaces that come in contact with food.

Hardened Silicone Removal Paste Lugato Silicon Entferner suitable for the most sensitive surfaces. The tool can be used to clean painted structures, wood, natural stone, tiles and so on. The mixture does not spoil the structure of the material and does not affect the color and gloss of the surface.

Purifier Silicone Remover is available in the form of a gel and is designed to liquefy hardened silicone. The mixture is universal for all materials. The only requirement for the treated surface is that it must be absolutely dry. Silicone Remover has a high speed of action on cured silicone sealants. It is enough to keep the solution on the dirt for ten minutes, after which the sealing compound can be easily removed.

Removing from various surfaces

When choosing a suitable silicone dilution agent, the type of surface to be cleaned should be considered. Most types of solvent compositions have a limited scope and are not compatible with all materials.

Plastic

Hydrochloric acid can be used to dilute the sealant to a liquid state on a plastic surface. However, it is best to use special cleaning products for cleaning plastic products. There are formulations that effectively soften silicone without corroding the plastic.

Glass

It will not be difficult to remove a dried silicone-based mixture from glass at home. The material has a rather dense structure, so that the sealant cannot penetrate deeply into it.

You can dissolve the sealing substance on glass surfaces with white spirit, a specialized professional composition "Penta-840", kerosene or refined gasoline. The most effective line-up in this case will be Penta-840. It will take more time and effort to dilute the sealant with these other solvent mixtures.

Tile

Most organic solvents have a negative effect on tiles. If the solution gets on the ceramic coating, then the material in the treated area will lose its original shine. It is forbidden to use white spirit on ceramic tiles of poor quality.

When liquefying silicone sealant on a tile surface, avoid products that contain abrasive components. Small particles can spoil the appearance of the tile by scratching it. In this case, it is better to use lighter fluid or kerosene.

Hand skin

During finishing work, not everyone cares about their own precautions. When applying silicone formulation without gloves on hands, there is a high probability of getting the mixture on the skin. If the sealant gets on your hands and has time to harden, you can remove it with rubbing alcohol.

Soak a cotton pad with an alcohol solution and treat the contaminated skin area. Instead of medical alcohol, you can use alcohol-containing solutions, but in this case, the effect will depend on the concentration of alcohol in the mixture.

Textile

If the acid-based silicone composition gets on the fabric, it will be easiest to dissolve it with 70% acetic acid solution. The area with the solidified silicone composition is impregnated with vinegar, after which the liquefied mixture is mechanically cleaned off.

You can dissolve a neutral-type sealant with alcohol solutions. In this case, you can apply an alcohol-containing mixture to the contaminated area, or soak the item in a solution of water and medical alcohol until the sealant softens.

How to dilute cured silicone?

After choosing a suitable agent, you can proceed to the very procedure for diluting the sealant composition. First of all, you need to take care of your own safety. If the work will be carried out indoors, then it is necessary to ensure good ventilation of the room.

Work must be done with gloves, since chemical solutions, if they come into contact with the skin of the hands, can severely damage it. To protect the respiratory tract from harmful vapors, it is recommended to wear a respirator.

The procedure for liquefying the sealant is carried out in several stages.

- The dissolving composition is distributed over the contaminated surface. You can apply the product with a cloth or sponge.

- The solution is left in the contaminated area for a while. When using folk remedies, the time can range from several minutes to one hour. When the sealant visually becomes jelly-like, it can be removed. If a special liquefaction agent was used, then the exact time during which the solution must be kept on the sealant layer will be indicated on the product packaging.

- Solvent mixtures will soften the sealant to a jelly or gel consistency. You can remove the remaining liquid silicone with a dry sponge or rag.

- After removing the silicone-based mixture, greasy marks often remain on the surface. You can clean the surface from grease contamination with dishwashing liquid.

For information on how to properly remove silicone sealant from a surface, see the following video.

Some Recommendations

Aggressive agents are often used to liquefy silicone sealants. It should be borne in mind that chemicals can affect not only the frozen mixture, but also on the surfaces with which they will come into contact.

Before applying this or that composition to the sealing layer, it is worth testing the product on an inconspicuous area of the surface. If the material on which the sealant is applied has not reacted with chemicals, you can start processing the silicone cured mixture.

Do not use solvents containing a substance such as toluene to dilute silicone-based sealants. On contact, silicone and toluene enter into a chemical reaction that releases harmful vapors into the air. In this case, there is a great risk of getting poisoned.

The comment was sent successfully.