Black sealants: features and scope

Sealant is a relatively "young" material in the construction market. Previously, cracks in the walls were repaired with homemade mastics, all kinds of bituminous compounds and improvised means that could not be called optimal for repair work. The advent of a new, more airtight material has greatly simplified the process of facing work.

Varieties

The sealant is a versatile and multifunctional grout, therefore it is popular with both professional craftsmen and amateurs. There are different sealants for indoor and outdoor use.

They can be conditionally divided into the following types:

- polyurethane;

- acrylic;

- silicone.

To achieve an effective result, any grout should be used depending on the surface material, climatic conditions and the level of humidity in the air. Its task is to create a protective barrier of dust, pollution, odors, and mold. Manufacturers offer a wide range of sealants designed to work with metal, glass, wood, enamel, ceramics, natural stone. The main advantage of modern materials is their high strength and protective properties. And most importantly, they do not change their qualities even under the influence of weather conditions!

The only drawback of sealants is that most of them cannot be painted at all. However, this drawback is fully compensated by the color assortment: there is black, red, transparent (neutral) silicone.

One of the most sought-after sealants is black, used in construction and manufacturing. Consider the features of black sealants and their areas of application.

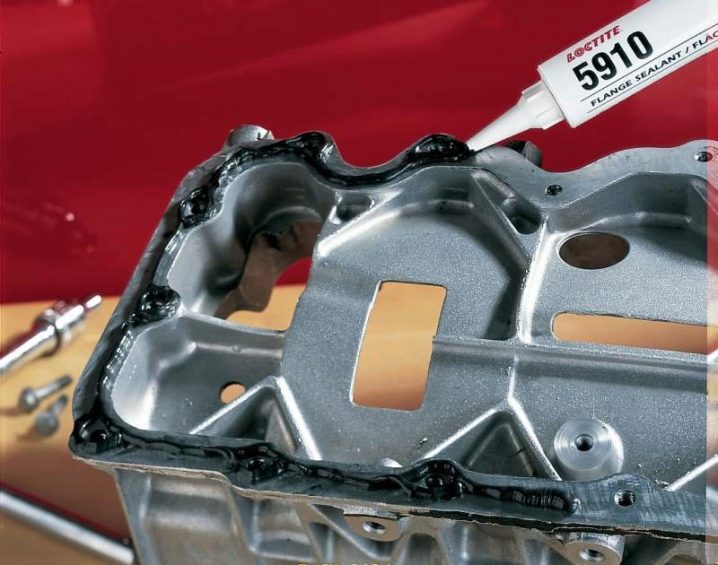

Silicone Automotive

This sealant can be used during a variety of technical applications, but it is mainly used to replace gaskets in automobiles. Differs in high resistance to engine oil, antifreeze, moisture. It tolerates high temperatures well and does not lose its qualities even after several years. Due to the thick consistency of the composition, the process of applying the product cannot be called complicated.

When working with this material, contact with gasoline should be avoided.

Bituminous

Compared to analogue black sealants, it is considered to be more modified. It contains a metallic pigment that makes the material more durable and gives it a light steel shade. It is characterized by super-resistance to external damage and moisture, elasticity, excellent adhesion to dry and damp surfaces.

It is used for sealing cavities and grouting joints in the roof. Suitable for the implementation of repair and construction work in the drainage system, chimney, ventilation. When choosing, it is important to take into account the fact that this material is highly toxic. Therefore, it is not recommended to use it for indoor renovation work.

For granite

Sealants for marble and natural stone are somewhat different from other groutings. They are easier to use, easily penetrate cracks, seams and pores of the stone. Moreover, the structure of such materials is more durable and elastic. In addition, it is convenient to work with such a sealant - when applied, it will lie down with a thick seam.

Such materials fell in love with consumers for their excellent performance: resistance to moisture, dust, dirt.The product is non-toxic and does not emit an odor when heated in the sun. You can no longer be afraid of mold: the fungicides that are part of the material prevent the appearance of fungus.

The use of a special sealant ensures a longer life for stone and marble coatings. It is equally well suited for both indoor and outdoor use.

Rubber

This material is produced on the basis of silicone rubber. These sealants are used for grouting wood and glass panels. Many craftsmen often use them as an alternative to grouting ceramic tiles.

There are two types of rubber sealant.

- Acetate for smooth surfaces. It is characterized by a strong, quickly weathered odor.

- Neutral for indoor use. Differs in excellent adhesion to enamel, glass, wood and ceramic surfaces. When choosing, it is important to know that in comparison with similar products, it has a lower strength.

Tape

It is made on the basis of butyl rubber, which makes it resistant to low temperatures and ultraviolet light. The excellent tackiness of the material makes the sealant easier to handle. They are popular in the field of roofing, and are also indispensable for installing thermal insulation, eliminating cracks and rusty coatings.

Polyurethane

For their creation, the main material is resins, polymerized using a special technology. They can withstand very low temperatures, so they are simply irreplaceable when processing double-glazed windows, swimming pools, interpanel seams. There are sealing (for dry surfaces) and waterproofing (for wet surfaces) compounds.

All sealants of this type do not allow water to pass through and must be painted. They are distinguished by economical use and long shelf life.

Of the minuses, a fairly high cost can be distinguished. Nevertheless, the quality of the material fully compensates for this disadvantage. When choosing, it is important to consider that this type of sealant is considered the best today and is suitable for working with metal, wood and tiles.

In addition to the above black sealants, there are also varieties such as:

- aquarium sealant adhesive used in the production of aquariums and terrariums;

- sanitary, for the treatment of showers and toilets;

- low modulus, for grouting joints between panels;

- electrical insulating.

Scope of use

In fact, almost all stages of repair work require the use of sealants.

During outdoor work, they are necessary for:

- sealing cracks and joints of window and door blocks;

- fixing marble or granite slabs;

- sealing joints during roofing works;

- sealing glass structures;

- sealing joints of vinyl cladding.

The range of application of these funds during internal work is no less wide:

- sealing joints during installation of suspended ceilings;

- sealing the seams of window sills;

- sealing of various parts;

- sealing plumbing pipes, sewerage, shower, bathroom mirrors.

It is impossible to list all the possible applications of the sealant. Specialists working with this material never get tired of finding new methods of using it. This also applies to private craftsmen who come up with non-standard ideas for the use of silicone sealants.

Popular brands

One of the market leaders among black sealants is recognized as a multi-purpose compound Abro based on silicone. It is used during the installation or replacement of automotive gaskets. Loved by consumers for the fact that it takes the desired shape well, tolerates shear, stretching and compression. Resistant to gasoline, various automotive oils, brake fluids, antifreeze and moisture. Can be applied at high temperatures (260 ° C).

Black sealant-gasket brand is no less in demand Felix.

It is also common in the automotive industry and is necessary for sealing the following auto elements:

- glasses;

- dashboards;

- finishing panels;

- hatches;

- headlights;

- sidelights;

- turning and brake lights;

- body body parts.

Suitable for use outside, inside and under the hood of a vehicle. It tolerates low and high temperatures (from -75 ° С to + 399 ° С).

For roofing work, many consumers choose Polish bitumen sealant Tytan black color. Made on the basis of rubber, it is highly plastic. That is why it is most often purchased for filling cracks and seams. It is suitable for surface treatment of materials such as corrugated metal, sheet metal, roof tiles, bitumen. Due to the thixotropic structure, it is easy to use - it does not drip from the tube during application.

How to distinguish the original manufacturer Abro sealant from fakes is described in the video.

The comment was sent successfully.