Acrylic sealants for wood: properties and application features

If you are starting to renovate a room, a sealant will definitely come in handy. It is used at certain stages of work. If you choose a colored joint sealant, then it will become a striking decorative element. It is quite difficult to wash off such a composition, so you need to work with it carefully.

Peculiarities

The sealing compound is a thick viscous mass in the form of a polymer-based paste. The sealing effect occurs when the compound hardens and the solvent evaporates.

Funds are divided into 2 types.

- For work with slight deformation. For example, in order to fix decorative wooden elements, wooden skirting boards at the final stage of laying the parquet.

- For processing seams. Suitable for work with high deformation, such as cracked surfaces between the timber of houses.

Sealing compounds for wood coatings must meet the requirements:

- reduction of heat loss;

- getting rid of cracks and cracks in wood;

- protection from wind and draft;

- 20-year service life at least;

- no specialized skills are required to work with them;

- the ability to use both outside and inside the premises;

- hygiene and environmental friendliness of the material;

- temperature fluctuations do not affect the material in any way;

- good adhesion to wood surfaces.

The wide range of sealant manufacturers can make it difficult to choose.

To decide, you need to consider:

- area of use;

- types of load;

- factors affecting the processed structure;

- components of wood sealant.

The proposed compositions are for work with windows, frames, roofs, as well as for indoor and outdoor work. There are also universal wood sealants.

Types of means for sealing

There are various sealants for wood on sale: based on acrylic, silicone, as well as bituminous.

Acrylic based wood compound

Such a sealant is used for internal work. Its advantage is that you can paint the surface treated with it.

The final finishing is carried out with varnish or acrylic paint. In production, there are waterproof and non-water resistant sealants.

Waterproof compounds

Waterproof ones are more in demand, as they, in addition:

- resistant to temperature fluctuations;

- good connection of porous surfaces;

- dry after use in a day;

- steam is passed (no condensation is formed);

- affordable;

- easy to use (no solvents or heating needed, you can work indoors);

- High Quality;

- long-term operation is possible (does not change color, is not exposed to ultraviolet radiation);

- environmentally friendly;

- fireproof, as they are free of toxins and solvents.

Sealing compounds

Acrylic sealing compounds have low elasticity - this is their only drawback.

When working inside a building, it is very important to choose the correct color of the sealant.so that the seam is not visible. Although sometimes contrast can be a design decision. This is especially beneficial when you need to visually change geometrically irregular rooms.

When choosing a sealant for decorative materials, laminate, parquet, it must be borne in mind that the final color will appear when the work is completely dry.

The color scheme is different for each manufacturer. There are usually about 15 tones on sale. The most used: white, "pine", "oak", "wenge". For the ease of choosing a client, most firms offer to use a palette or see samples. If a unique shade is required, then it is recommended to use white and a special color scheme. If you mix them carefully, you get the desired color. For wooden coatings, the sealant is suitable as a destroyer of cracks in wood, boards, it is very convenient to remove cracked coatings around windows and doors.

Specifications

The hermetic composition containing acrylic has the following properties:

- the width of the seam should be less than five cm;

- seam thickness - less than fifty percent of the width;

- a standard tube is enough for five meters, ten mm wide and six mm thick;

- t coverage from +5 to +32 degrees Celsius;

- t work from - 40 to +80 degrees Celsius;

- painting can be done in twenty to thirty days, while the humidity is fifty to sixty percent;

- the surface sets in about an hour;

- frost resistance - up to five cycles.

Before doing the work, you need to take into account all the technical characteristics, only then a good result is guaranteed.

Areas of use of acrylic sealants

Sealing of seams is carried out using waterproof and non-waterproof compounds based on acrylic. Experts advise using them inside buildings. Frost-resistant compounds are often used outdoors. The same sealing substances are used inside the house.

The non-water-resistant sealant has a specific composition, therefore it is used in houses with normal humidity. Suitable for working with plastic, wood, polystyrene, expanded polystyrene, drywall.

It is worth noting that with the help of an acrylic sealant, you can attach decorating elements, as well as fill the seams between tiles, clinker. This tool ideally joins wooden parts, because it has a positive adhesion to this material. A sealant will come in handy if you need to fix furniture.

An acrylic-based product with waterproof capabilities is used much more often, it has increased adhesion to surfaces: wood, plywood, ceramics, tiles, aerated concrete, foam concrete, concrete slabs.

Sealing agents are used on surfaces that are both very uneven and perfectly flat. It is widely used in kitchens, bathrooms, where the humidity is higher than in other rooms. It is an excellent formulation for use in wooden window frames.

Seams in the wooden flooring are sealed with acrylic. Firms that produce acrylic sealants produce colors that are close to the types of wood. Acrylic compounds are used as a sealant between logs. Today it is fashionable to build houses, baths, summer cottages, hotels from wood - a pure material. Therefore, the classical technology is always applied. Previously, hemp was taken for this, but it is short-lived.

The acrylic sealant is matched to the color of the wood product used. For outdoor work, it is advised to use a product that is resistant to high humidity. The seams are processed outside and inside, which helps to avoid drafts, dampness, and rodents. Seams between the log and the foundation are also processed. Acrylic has good adhesion to these surfaces.

Acrylic is simply irreplaceable for making a log house. They are finished at the finish line. For houses made of laminated veneer lumber, cottages, finished "block house" also take acrylic sealing mixtures in shades of wood. Wood tends to dry out over time, and an acrylic-based sealant is essential to seal the cracks.

Sealing agent is used to join ceramic tiles, tiles with surfaces.This material is quite easy to use compared to the various glue options. During the laying of the tiles, there is enough time for adjustments, so the quality of the work is much higher. The sealant perfectly protects against moisture inside. The most popular choice is white sealant, as it works well with all tile options.

For concrete surfaces, the acrylic composition is suitable for repairing window sills. The gaps between the slab and the wall are sealed with it. Having carried out sealing in this place, the absence of a through flow of air and dampness is ensured.

Specialized sealants for window frames are available. Concrete and wood surfaces can also be treated with this product. Thus, the scope of application becomes more extensive. So, they can handle cracks in logs or between the wall and the floor.

Means issued for laminate flooring are also effective in processing euro lining, "block house", plywood, MDF.

When buying a sealant, you should pay attention to the elastic ability. When the coating for sealing is exposed to vibrations, it is worth buying a frost-resistant compound. It is more elastic due to its composition. Special additives allow it not to collapse at temperatures below zero.

The acrylic sealing compound is recommended by craftsmen for work with the roof. At the same time, they completely forget about the poor resistance of acrylic to the flow of water, temperature drops, and elevated temperatures. Roofing material heats up to 70 degrees in the sun, which is bad for acrylic. Installation of windows in the attic will not do without a sealant. For working with the roof, sealants that include silicone are more suitable.

Tips for working with sealants

To work with seams, high quality crevices, you need to follow some rules.

- Be sure to clean the treated surfaces from dust, paint, dried sealant.

- If the work is carried out outdoors, the surface is cleaned of snow and frost.

- To increase adhesion, you need to prime the surface.

- If the crack is very deep, a PE foam tape should be used, which limits the depth and saves the sealant.

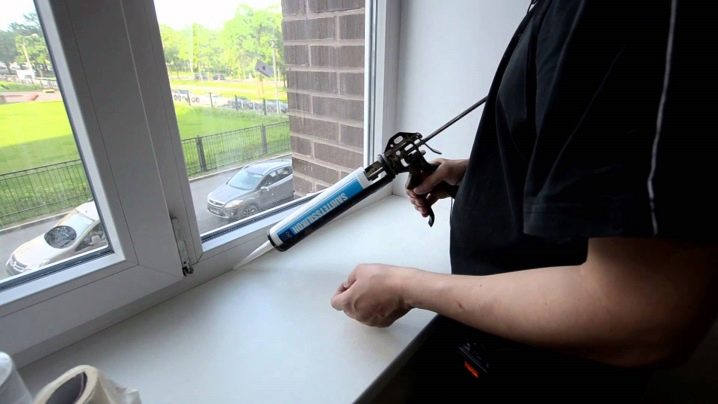

- To use material sparingly, assembly guns and pumps are used. The gun is used on small cracks and seams.

- Outside, no work is done if it rains or rains.

- The sealant should dry in dry weather.

- Also, work is not performed at sub-zero temperatures.

- It is better to turn to specialists if you do not have time, because specialized tools and technologies are needed for work.

- When processing the seams, you need to monitor the filling.

- The product should fit snugly on a wooden surface;

- Drying time can be up to several days.

Almost all hermetic products have a long service life, but this does not mean that you need to buy the cheapest one. If the sealing is done correctly, then you can forget about the problem associated with irregularities and defects on wooden surfaces for a long time.

Production of acrylic sealants

All the advantages of acrylic-based sealants are present exclusively in high-quality products. Very often, one-day firms offer fake products, so you need to use the goods of trusted firms.

Most popular: Polish, German, Russian. Verified manufacturing companies:

- Novbytkhim - a domestic company that produces acrylic products in tubes

- Zigger - German company. The products produced by her are suitable for wooden floor coverings, as well as seams, cracks

- Henkel - manufacturer from Germany. Produces frost-resistant products

- Belinka - a company from Slovenia. Produces elastic products for parquet and general work

- Loktite - Russian frost-resistant sealant for fixed structures

- Penosil - another domestic company, its sealants have the highest adhesion. You can do work with plastic

- Titanium - manufacturer from Poland. The products have an excellent price-quality ratio.

You can also highlight the "Accent 125", which is of high quality. You should not use unfamiliar cheap sealants, they, as a rule, are of poor quality and short service life.

Summarize

Acrylic sealants have become very popular in renovation work. The advantageous distinction of these products is their low price, ease of use, and good technical performance. It is the most popular type of this compound when working with concrete and wood surfaces. Excellent for sealing gaps between wood and ceramics.

Gypsum, alabaster, putty now does not have to be used at all, because they can be replaced by acrylic sealant. Because of its qualities, it competes with silicone-containing products. Such material also has disadvantages that must be taken into account in order to avoid some problems. The main function of the sealant is to fill voids in fixed and inactive structures.

For the properties and features of the use of acrylic sealants for wood, see the following video.

The comment was sent successfully.