All about castellated nuts

screw Is a product made of metals or polymers that holds parts together, which is necessary for various works. There are several types of this fastener. In this article, we will talk about one of them - castellated nuts.

Peculiarities

This is a type of metal products with an internal thread, intended for fastening parts in particularly critical places.

Its main purpose is to prevent self-unrolling.

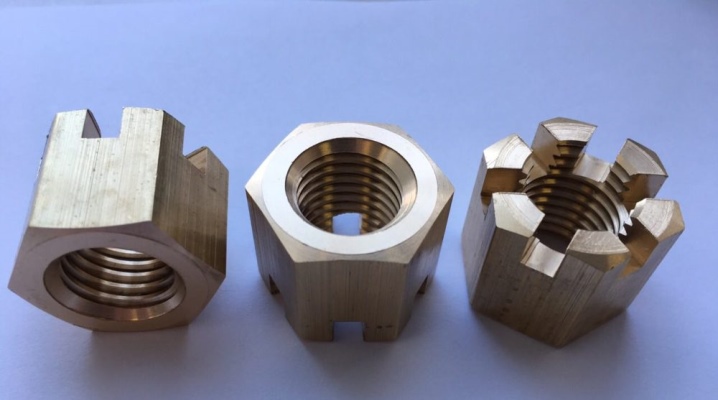

Externally castellated nut looks like a hexagon with vertically cut slots (the number of splines may be different, this is influenced by the diameter of the threaded connection). Because of this unusual appearance, it got its name. These "teeth" are the main feature of this fastener.

The bolt has special hole, after tightening the nut, it is inserted into it cotter pin, or it is fixed with a safety wire. As a result of these manipulations, the connection gains additional reliability.

And crown products are characterized by increased manufacturing complexity... This process takes much longer than the release of conventional nuts with the used stamping or casting methods.

The most common manufacturing method for castellated nuts looks like this: a multifaceted bar of the required diameter is taken, blanks are cut and subsequently machined mechanically. Because of these additional complications during production, products of this type are more expensive.

Due to their high cost, it is economically impractical to use them instead of conventional nuts.

Views

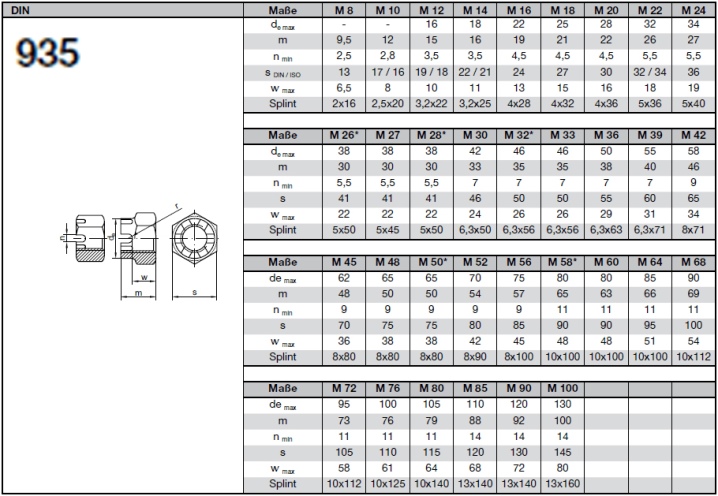

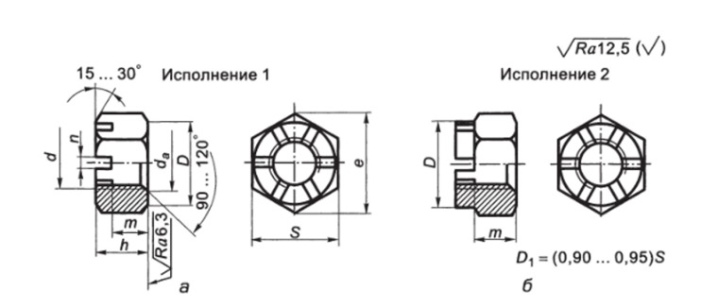

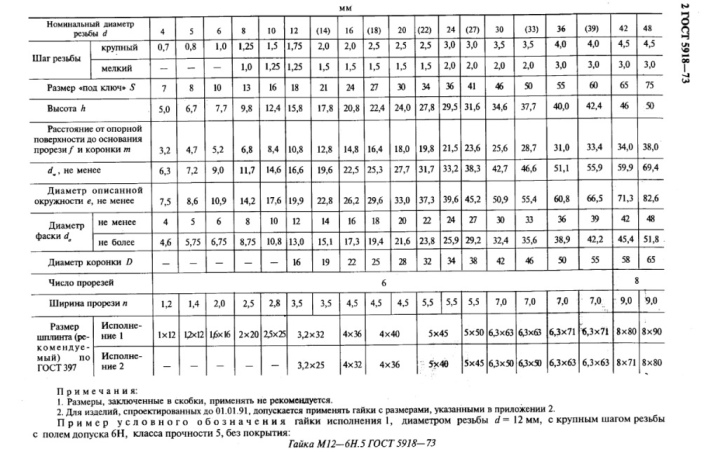

The main regulatory document according to which slotted and low slotted nuts are manufactured is GOST 5918-73. And also used European standard DIN 935, according to which a slotted product is considered to be up to a thread diameter of M10, and above it is a castellated one.

All fasteners are divided into three types according to the accuracy class:

- A (increased);

- B (normal);

- C (reduced).

The castellated nut belongs to class B.

Another characteristic is strength... In total there are 7 strength classes, but in real life, professionals usually identify products with normal strength and high. Experts say: for a long service life of a threaded connection, it is necessary that bolts and nuts correspond to the same strength class. And for maximum reliability, the fastener must be more reliable than the bolt, at least one step and secured with a cotter pin.

The third parameter is height... Nuts can be low, high or elongated. The height of the product is determined according to the following principle: 0.5-0.6 thread diameters for small ones, for the second type - 1.5, for increased - 3.

Slotted and crown hardware are available in low and regular versions.

The material from which these products are made: this various types of steel - both conventional and stainless, non-ferrous metals or plastic.

The shape of the products is mainly hex, but also come across octahedra... And also they can be constructively performed in two forms, with chamfer (version 2) and without (version 1).

Dimensions (edit)

GOST defines the dimensions for crown-type nuts with a thread diameter from 6 to 48 mm. A total of 17 sizes according to the standard, of which 11 and 6 additional are offered for production (it is not recommended to produce them on an industrial scale due to their low demand).

Thread type can be different: with a large step and a small one.

The ratio of all parameters is described in more detail in a regulatory document of a domestic or European standard.

Armed with a calculator, you can find out the average weight of a product with and without a chamfer... The standard indicates the approximate weight of one thousand products in kilograms based on the diameter. For example, one ton of castellated nuts in the first version with an M12 thread diameter weighs approximately 20.881 kg.

Product information can be obtained from markings... In particular, if The symbol is M20-6N. 5 GOST 5918-73, then it stands for:

- diameter is 20 mm;

- tolerance field 6H;

- reliability class 5;

- type of execution first;

- no special cover.

And if - 2 M30-6N. 5 GOST 5918-73, then the thread diameter is 30 mm, the second type of execution, the rest is the same.

Applications

Before buying castellated nuts, very it is important to decide on the environment of use and purpose... If the fasteners will be used in normal conditions, then you can purchase and use hardware from ordinary steel. In the event that the surrounding atmosphere suggests unfavorable circumstances, it is advisable to use products made of materials that are resistant to corrosion. And if the environment is chemically aggressive, stainless steel or non-ferrous metal options are best. All castle nuts are available in various designs.

In each specific case, the correct decision would be to first consult with specialists and independently familiarize yourself with the regulatory documents.

These fasteners are widely used in various industries, very often found in everyday life. They have proven themselves most well in the automotive, carriage-building areas of production. They are also irreplaceable in mechanisms that constantly face high loads or increased vibration.

There is no need to save on this type of hardware, because the strength of the bolted connection and the entire structure as a whole depends on their reliability.

In the following video, you will learn how you can use a castellated nut.

The comment was sent successfully.