Rivet nuts: varieties and fasteners

For the production of various structures, products and parts, certain materials are required. And to fasten the parts together, special fasteners are used. In such work, one cannot do without rivet nuts, which are offered in a wide range. This tool is made from different materials, but it is always characterized by strength, reliability and durability. To choose the right rivet nut, you first need to familiarize yourself with its characteristics.

Description and scope

The rivet nut is an important element of the connection, which is used at different stages of the production of many products and structures.... It is difficult to do without such an important constituent element. Thanks to this fastener, you can get a permanent connection in a place where it is not so easy to reach, or it is impossible to disassemble the product. For working in a small space, it is recommended to use such elements.

The use of this fastener allows you to carry out installation in a short time without much effort. Nut rivets can be installed as single parts or as a finished product. You can rivet the product on one side.

This type of fastener allows you to significantly reduce production costs, speed up the workflow, and also avoid many mistakes during installation.

Of course, it is useful to have the appropriate equipment for installation. If you have a special riveter at your disposal, the job will be completed in a few seconds. Another advantage of using such a tool is that the materials to be bonded will not deform. However, it is necessary to correctly select rivets in size, taking into account the type and thickness of the surface that will be joined. Conventional nut elements are not suitable for fastening thin steel sheets, as they are not as durable. Internal thread makes it possible to connect efficiently, firmly and for a long time. The diameter of the hardware affects the reliability of the nut rivets.

This element is often used in the automotive industry when a vehicle needs to be repaired. Disassembling the interior is inconvenient and time-consuming, so the use of rivet nuts is the best solution. However, the operation of such fasteners is wide, since it has a lot of advantages, excellent characteristics and its own characteristics.

Species overview

Nut or screw rivets are available on the market in a wide range... Each type of this product has its own characteristics and advantages, as well as the scope of application. Therefore, first you need to understand the characteristics in order to make the right choice. The rivets differ in their design, namely the internal thread, as it forms the locking belt during compression.

Distinguish these products by type of head and type of thread. Nut rivet М4 - 8 has a non-separable connection, therefore it is suitable only for conditions where movements are limited, if it is impossible to access the back of the part. The screw sample belongs to the category of collapsible rivets. The profile of the leg also differs from product to product - hexagonal and round. The type of collar can be open, closed, hidden, small and large, which should also be taken into account when choosing a fastening element.

The characteristics of the rivet affect its purpose, since electrically conductive products can be found on the market, with vibration isolation, inch thread, with marks to make visual identification, etc.

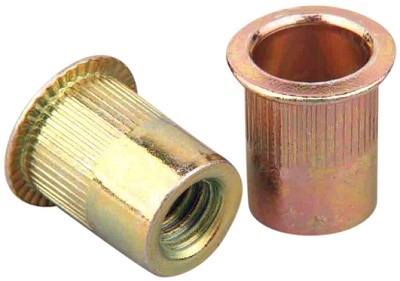

Hex rivet is intended for fastening sheet profiles to each other. Such a nut has the form of a sleeve with an internal thread. This element is an excellent alternative to welded joints, so you can fix products with thin-walled material. It is often used in the manufacture of furniture, electrical devices, air conditioning systems and the manufacture of metal cabinets. The blind nut is designed to create threads when using screws, studs and bolts. If tightness of the fastening is required, it is better to choose this option. Thanks to the standard collars, deformation of the base material is prevented, since the contact area is large. To install such a rivet, a hole must be drilled.

Cage nuts are used when there is no fastener. If there is a hole, but there is no thread, this product will help out. However, here you will need a special tool that is designed to work with blind nuts. The most common form of riveting nuts is cylindrical. It is sturdy and easy to work with.

Materials (edit)

Rivets are made from different components, so each has its own indicator of durability, strength and service life.

- Steel products (galvanized and stainless) can be called the main type of fasteners, which are excellent for creating high-strength assemblies of sheets, structures and metal parts.

- Copper and aluminum It is used for the manufacture of threaded rivets, when aesthetic fasteners are required, which are often needed exclusively for decorative purposes.

- Rubber nuts differ in that they can be reused. Thanks to them, you can get threads of irregular shape and even non-standard sizes. It should be noted that rubber guarantees the tightness of the hole, and also reduces shock and vibration loads. This material prevents static charging.

- Bronze suitable for the manufacture of rivet nuts where a minimum spark rate is required. Carbon steel is a versatile material that can be threaded to fit standard connections.

Usage Tips

First you need to decide what exactly you will use the rivet nut for in order to take into account the characteristics of the tool. The thread size is of great importance and must be matched to the fastening parameters. When it comes to a new installation, it is necessary to remove the dimensions from the hole in order to avoid damage to its side parts.

As for the material, if you are going to use the nut in a damp room, it is better to choose a product with corrosion resistance. Elements made of stainless steel, steel coating or aluminum are suitable for such parameters.

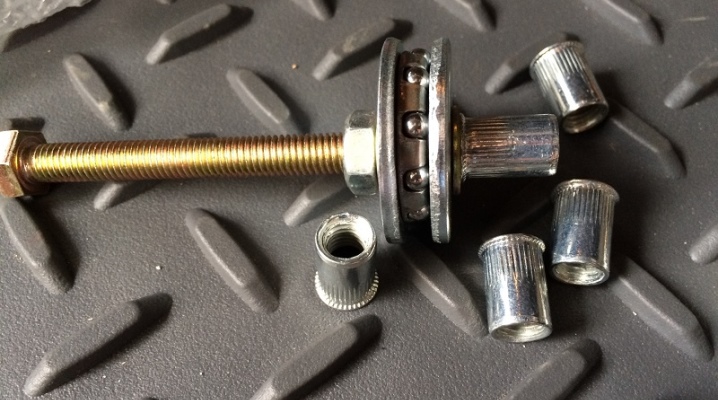

A bolt and nut can be used to install a threaded rivet if the correct tool is not at hand. However, it will be much easier and faster if you use a pneumatic, battery or mechanical riveter. The product must be screwed onto the thread, after which the fastener is inserted into the hole, and the tool turns on. The rotation will be fast, so the threaded portion will stretch out and a bulge will form around the portion. The tabs need to be pressed against the back of the panel to get tightness.

When the nut is secured, it rotates in the opposite direction and releases from it, leaving the inside of the fastener intact. After such a simple work, it is not necessary to carry out additional finishing or painting the surface. The nuts can be installed at any time.

If you are going to fasten materials with a thickness of more than 4 mm, it is better to choose a rivet with an M10 indicator, for thinner surfaces, fasteners M8 and M6 are suitable, and for millimeter thicknesses, it is recommended to use M3.

For information on how to install a rivet nut without a rivet, see the next video.

The comment was sent successfully.