All About Flange Nuts

The idea of flange nuts, at least in the most general form, is extremely desirable for any person who does something with his own hands. Knowing the provisions of GOST on nuts for flange connections, he will apply them most effectively and consciously. Attention should be paid to hex nuts M6 and M8, M10 and M16, nuts of other sizes, materials used, dimensions and weight.

Description and types

The story about nuts with a flange cannot escape the analysis of GOST for these important and critical products. More precisely, We are talking about the Russian standard 50502-93 "hexagon nuts with flange of accuracy class A". Threads, tolerances, surface quality requirements, mechanical characteristics, acceptance, storage and packaging procedures are standardized. The annexes to the standard provide data on the theoretical weight of hardware and the procedure for checking the diameter. The flanged hex nut must additionally comply with DIN 934.

Such products are needed for mechanical engineering, the construction industry. They are also used when creating various pipelines.

Important: The weights given in the DIN standard are purely approximate.

As for the nuts with nylon ring, then they obey the requirements of DIN 985. The role of the ring is obvious: it “grips” the bolt from the outside and helps it hold in place more firmly.

Even if such fasteners become loose (which is quite possible), the plastic material will not allow it to fly off. At the same time, it is important to understand that a product with a nylon ring is disposable, and it will not work to rearrange it to a new place. Also, a special variety of flange nuts has become quite widespread. Such products are usually coated with zinc using galvanic technology. They are used in close contact with a special screw; such a connection prevents unintentional loosening.

Attention should be paid to the nuts with a serrated flange.... Such designs are usually created in accordance with DIN 6923. Externally, they resemble a hexagonal ring and have an extended flat side. Thanks to this design, there is no need to back the washer. The clamping area will be large enough anyway.

With regard to the placement of the teeth at an angle, it is intended to block rotation, weakening the tightening. This property makes it possible to use such fasteners for locking structures that are exposed to strong vibrations. Press washer nuts can be reused. But this is allowed only under one condition: the ribbed part is not crumpled or worn out. It should be borne in mind that corrugated flanges, due to strong tightening, can damage the paintwork or anti-corrosion coating.

This moment is already present before the application of the tightening force, and also after the cessation of tightening, up to unscrewing. The required parameter can be measured directly in the process of twisting the hardware. Most often, self-locking nuts are produced by making a "cold heading" on a multi-position machine. The basic strength requirements are the same as for conventional structures. If strength class 5 or 6 is specified, additional heat treatment is not carried out; for categories 8 and 9 it is desirable, for categories 10 and 12 it is mandatory.

But grease of any kind does not at least impair the fixing qualities of such products. The self-locking nut provides the necessary locking simply by means of frictional force. This force appears when the deformed part of the thread on the nut itself contacts the thread of the rod parts.Intentional deformation blocks free screwing in or out of fasteners. Engineers say in such cases that "prevailing torque" develops.

It is allowed to manufacture self-locking nuts with a protective coating of various kinds or without such a coating.

Engineers appreciate the quality of the structures with spring insert, supplemented by a compressed coil. Crimping can be done "on an ellipse" or "on a polyhedron". In these cases, the requirements in ISO 2320 apply. It should be understood that it is not always possible to assemble connections with a given torque level.

Due to changes in the coefficient of friction, it can actually change by 25% in both directions and even more. The conclusion is simple: if you have to assemble a critical connection, it is wise to prepare an assembly system in which the tightening force is monitored. Another nuance is that the design and dimensions of the locking elements are not standardized. Therefore, in different cases, they can differ significantly. Much also depends on the industrial policy of individual manufacturers.

Most often, self-locking fasteners are used in automotive and similar equipment.... Their concentration is highest in critical and heavily loaded vehicle units. A self-locking nut, however, is rarely used in Russian conditions. The release of such products by the domestic industry, especially outside the automotive industry, is quite small. The overwhelming majority of products of this kind are delivered from abroad.

The round nut is quite widespread. It can belong to spline, grooved and straight-spline varieties. In the corrugated version, knurling is performed along the outer surface of the cylindrical element. This makes it easier to twist by hand. Tall flange nuts, plumbing retainers, and large flange versions may also be encountered.

Areas of use

Such fasteners can be used:

for pipe connections;

for construction purposes;

in various branches of mechanical engineering;

for wood (and wood products);

in other cases where reliable nuts are needed interacting with screws, bolts.

Materials (edit)

Flanged nuts are made from various types of steel. Most often, carbon and stainless grades are used. Magnesium, silicon and manganese are usually added as additives to carbon steel. Alloying components significantly change the properties of the starting material.

However, stainless steel grades are distinguished by their greater resistance to negative weather phenomena.

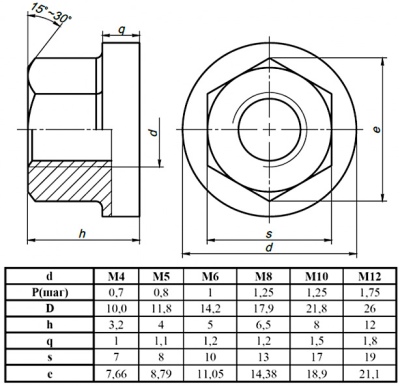

Dimensions and weight

It is most convenient to present the relevant information in the form of a table.

Brand | Height (mm) | Width (mm) | Depth (mm) |

M4 | 120 | 65 | 10 |

M5 | 4,7 — 20 | 8 - 30 (turnkey) | - |

M6 | 30 - 160 (most often 120) | 65 (turnkey) | 10 |

М8 | 8 | 17.9 (maximum width) | 10 |

M10 | 10 | 15 | - |

М10х1 | 4 – 20 | 5,5 – 30 | - |

M12 | Before 18 | Up to 25 | 15 |

M14 | 14 | 21 (turnkey) | - |

M16 flange nuts are usually made of high-quality steels. Carbon metal grades are predominantly used. Considered interaction with various types of metric fasteners. This nut has the following dimensions:

thread section from 5 to 20 mm;

cutting step from 0.8 to 2.5 mm;

height from 4.7 to 20 mm;

turnkey width from 8 to 30 mm.

Typical for M18:

cutting step 1.5 or 2.5 mm;

section inside from 18 to 19.5 mm;

head height - 14.3 - 15 or 16.4 mm;

wrench size 27 mm.

M20 nuts have the following dimensions:

height 2 cm;

turnkey size 3 cm;

flange section 4.28 cm.

According to DIN 6923, the weight of 1000 pieces of nuts is normally:

M5 - 1 kg 790 g;

M6 - 3 kg 210 g;

M8 - 7 kg 140 g;

M10 - 11 kg 900 g;

M12 - 20 kg exactly;

M14 - 35 kg 710 g;

М16 - 40 kg 320 g.

M4 flange nuts are designed to create some pressure on the joint surface. Typically, a household package contains 25 pieces. Such products are made of galvanized steel. As for the M6 hex nuts, they can be packaged in 0.581 kg. Basically, the right-hand thread predominates.

As for the M6 hex nuts, they can be packaged in 0.581 kg. Basically, the right-hand thread predominates.

See the video about the flange nut below.

The comment was sent successfully.