The subtleties of the process of warming the basement base from the outside

The thermal insulation of the basement basement is exposed to significant loads - mechanical and temperature influences, the influence of moisture. This determines the criteria for choosing a heater and the features of its installation.

Peculiarities

A common misconception is the judgment that the foundation does not coexist with living rooms, and therefore does not need insulation. However, such a position is fundamentally wrong, and thermal insulation of the base is needed for a number of reasons.

First of all, insulation serves to protect the foundation from freezing, which means it allows you to preserve the operational characteristics of the structure and extend its service life. As you know, the reliability of the entire building depends on the strength of the base.

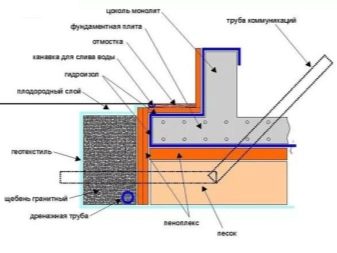

An important point - high-quality thermal insulation of the foundation should include not only the insulation of the outer walls of the basement, but also the blind area around the entire perimeter of the building.

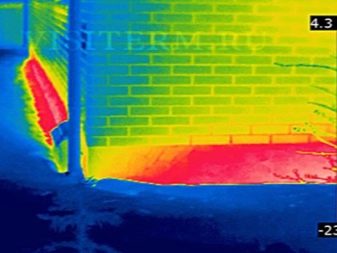

An impressive reinforced concrete base without thermal insulation becomes a cold accumulator, from which it spreads to the supporting elements. Even in the presence of an insulating layer on the floor and walls of the object, powerful heat losses are detected, the source of which is the foundation. At the same time, its insulation allows you to reduce them to 20-25%.

Another important advantage of the insulated base is a significant reduction in soil swelling in winter. This is due to the fact that the soil near the foundation simply does not have time to freeze. With proper insulation, the soil freezing zone will not reach the walls of the foundation. This, in turn, allows maintaining approximately the same temperature regime of the foundation along its entire height. But it is they that cause the internal stresses of the reinforced concrete base, leading to its rapid wear.

As you know, any foundation has its own coefficient of frost resistance, on average equal to 200 freeze / thaw cycles. Of course, we are not talking about 200 operating winters, since freezing and thawing of the foundation during one winter can occur a large number of times. Competent insulation prevents the foundation from freezing and, accordingly, allows you to reduce the number of cycles of freezing and defrosting the foundation during the cold season.

In addition, external insulation of the basement allows you to move the dew point closer to the outer surfaces, so moisture will not accumulate in the thickness of the foundation, causing erosion of concrete and corrosion of metal elements. Finally, the insulating layer serves as a kind of barrier to groundwater.

If we talk about the pile foundation, then it is less susceptible to the influence of swelling soil and groundwater. However, the reinforced concrete grillage used in this case, in the absence of insulation, becomes a source of cold. However, other problems characteristic of the strip foundation also become relevant for the grillage.

In addition, usually in the space between the ground and the overlap of the first floor of a private house, vital communications are laid, the freezing of which is unacceptable. It is the insulation of this part of the house that will ensure their uninterrupted operation.

An important point: these properties can be achieved only when the basement is insulated from the outside.

Internal insulation can give a slight reduction in heat loss, however, if the insulation is incorrect, there is a high risk of increasing humidity in the room. Naturally, the appearance of "cold bridges", a decrease in the level of soil swelling and protection of the foundation cannot be provided with internal insulation.

Insulation requirements

The basement part of the foundation is more susceptible to low temperatures, mechanical and chemical influences, and moisture compared to other elements of the house. Based on this, the insulation used should primarily be characterized by the following properties:

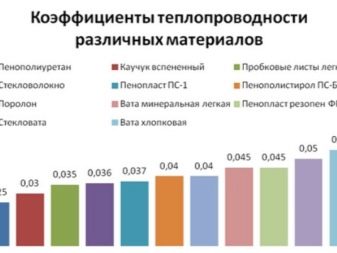

- low coefficient of thermal conductivity;

- moisture resistance;

- resistance to temperature extremes;

- high mechanical strength.

There are usually no special requirements for vapor permeability, they try to select a material whose vapor permeability indicators are close to those of the base material.

Fire hazard in this case is also not a primary characteristic, since most of the insulation will be buried underground, that is, it will be located in the least fire-prone place.

To protect the insulation, you should immediately pick up a decorative material - plates, panels, siding. Moreover, it should not be for the facade, but for the basement.

Materials (edit)

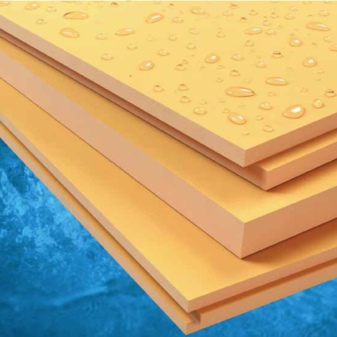

Typically used as a heat-insulating layer extruded polystyrene foam plates... The material has high thermal efficiency, in addition, it does not allow moisture to pass through. It is worth noting the ease of installation of the plates. They have the correct geometry (produced in the form of rectangles), a smooth surface. It is enough to glue the boards to a previously prepared surface, avoiding the formation of gaps between them, since they will become "cold bridges".

Among the disadvantages of the material is its ability to release styrene, which is not useful for humans. However, with external thermal insulation, environmental requirements are not as strict as in the case of internal insulation. The material belongs to combustibles, it is attractive to rodents who like to make moves in it.

Expanded polystyrene plates can be of 2 types - polystyrene foam and extruded polystyrene foam. By the way, on the basis of the latter, a more modern modification of styrene insulation is also produced - penoplex. Penoplex insulation will give the best effect, in addition, the material has tongue-and-groove edges, which simplifies installation and makes the material joining more reliable.

Another effective insulation is polyurethane foam, also having a low coefficient of thermal conductivity, resistant to moisture, temperature extremes. Unlike expanded polystyrene, it is an environmentally friendly and non-combustible material.

Insulation with polyurethane foam requires the involvement of specialists - the material is sprayed over the surface of the base, forming a powerful and warm layer.

Due to the peculiarities of the application, it is possible to achieve strong adhesion of the material to the surface, filling all cracks and voids with it. This, in turn, guarantees the absence of the appearance of "cold bridges".

Both insulation materials (expanded polystyrene and polyurethane foam) do not allow surfaces to "breathe". For concrete and reinforced concrete foundations, this is not a problem, however, on wooden surfaces (for example, when using wood to fill the space between the first floor ceiling and piles), their use is not recommended. Excess moisture will remain in the thickness of the wood, which will lead to its decay.

Another important point is that both materials are unstable to UV rays, therefore, immediately after thermal insulation, it is necessary to proceed with the installation of a protective and decorative layer of the foundation. It is unacceptable to store the material (foam plates or its extruded variety) without packaging. Otherwise, the products will lose their performance characteristics.

Finally, insulation and foam foam are popular. It is a roll material based on polyethylene foam, equipped with a heat-reflecting foil layer. Foamed polyethylene itself has a low thermal conductivity, an additional increase in thermal efficiency is achieved due to the presence of a foil layer. It is capable of reflecting up to 97% of heat. To do this, it is not placed outside, but towards the inside of the base.

The advantage of the considered heaters is their versatility - they are suitable for any type of base (brick, concrete, reinforced concrete), can be covered with various materials for decoration (usually siding, facade panels).

It is not recommended to insulate the basement with mineral wool, which is so popular for wall insulation. This is due to the hygroscopicity of the material - accumulating moisture, it loses its thermal efficiency.

How to insulate with your own hands?

Ideally, the basement floor should be insulated even at the stage of pouring the foundation. Let us consider this process in more detail using the example of warming the base of the strip base. After pouring and hardening, stripping is performed. Next, it is necessary to free the surface of the foundation up to the sole by digging trenches along the base. Their width should be sufficient for the descending worker to make the necessary manipulations conveniently.

If the insulation is carried out in an already built house, then it is also necessary to dig trenches with the help of shovels to the very base of the foundation.

The next step is to prepare the base of the foundation. The surfaces must be free from dirt and dust and dried. Only in this case it will be possible to achieve good adhesion to the insulation.

If there are concrete build-ups and other irregularities on the surface, they should be eliminated using a sander with a stone and wood attachment. Cracks and cavities should be repaired with high-speed concrete putty. When using a classic cement mortar, you will have to wait for it to set, about two weeks.

Next, a layer of polymer primer is laid on the prepared surface. It is important to apply the composition in an even layer, excluding gaps. It is convenient to use for this a synthetic roller with a short nap, and in hard-to-reach places - a brush. The primer will improve the adhesion of waterproofing materials.

The next stage is the fixation of the waterproofing layer, represented by roll materials on a bitumen-polymer basis or membrane waterproofing. The choice of the specific material is up to the homeowner.

Bituminous roll materials can be glued to mastic (self-adhesive products) or fused with a gas torch. The material should be spread from the bottom up. When pasting corners, it is important that the sheet of material covers one side and goes to the perpendicular by 100-150 mm.

After the waterproofing work is completed, they proceed directly to the insulation. For fixing polystyrene foam boards, you can purchase ready-made adhesive for thermal insulation work. Its advantage is a good adhesion rate on vertical surfaces.

If a more economical option is needed, a dry composition of the building mixture is purchased. Another option for an adhesive base is the use of bituminous mastic. It is suitable if the insulation is glued to the roofing material. However, it is important that there are no organic solvents in the composition of the mastic, since they destroy polystyrene foam boards. The composition on a water-soluble basis that is most adapted for this type of work should be chosen.

Next, the glue is applied to the entire surface of the insulation board using a notched trowel. It is necessary to regulate the amount of glue in such a way that its excess does not protrude beyond the plate when gluing. If this nevertheless happens, the glue that has come out should be immediately removed.

The work is also carried out from the bottom up, the plates are pressed against the foundation, and after setting, you can start fixing the next one. If a two-layer insulation layer is required, the second row of plates is mounted in such a way as to avoid seams. That is, the second row is laid out with an offset relative to the first.

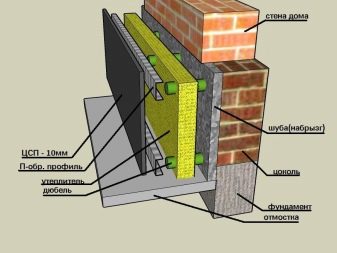

Fastening of heat-insulating material below ground level should be carried out only with adhesive. Above the level, it is recommended, in addition to glue, to use additional fixation with dowels - fungi. It is important that for the dowels, holes of a suitable diameter are first drilled into which the dowels are already inserted. Otherwise, cracking of the material for most of the slab cannot be avoided, which becomes a decrease in its thermal insulation characteristics.

If you find butt joints, they should be filled with construction foam. It is better to choose a composition released by the same brand as the insulation.

After the foam hardens, its excess is cut off with a knife.

In fact, the insulation can be considered complete, but it will be correct to protect the foundation from the chemical effects of groundwater. To do this, a fiberglass mesh is stretched along the entire perimeter of the foundation, on top of which plaster is applied with a thin layer using a compound for coating waterproofing. You can also use a special membrane. Only after carrying out these manipulations, you need to start backfilling the base.

It remains to protect the towering basement part of the foundation with a special decorative material. As a rule, these are wall panels, siding. Contact treatment with plaster or paint composition is possible. For this, the insulation is reinforced, covered in 2-3 layers of plaster, the finish layer of which is carefully sanded. After that, a decorative layer can be applied.

Advice

For proper thermal insulation, you need to choose the optimal thickness of the insulation. Too thin a layer will not cope with its functions, an excessively thick layer will cause unnecessarily increased loads on the foundation and financial costs.

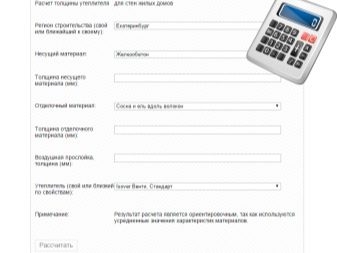

To calculate the thickness of the insulation, use the formula Rsum = hph / λf + hу / λу, where Rsum is an indicator of the total resistance of heat transfer, which the foundation should be characterized by. The unit of measurement is m² × ° K / W.

This indicator is a constant building value and is developed for each region, taking into account climatic conditions. You can get acquainted with the specific value in SNiP or by contacting local construction and design organizations.

The regulatory documents indicate 3 values of thermal resistance - for walls, coatings and ceilings. When calculating the thickness of the insulation for the basement, you should focus on the first indicator - for the walls.

- hf is the value of the foundation thickness (in meters);

- λf - coefficient of thermal conductivity of the material from which the foundation is made, the latter is also a constant tabular value;

- hу and λу are similar indicators for insulation.

The thermal conductivity coefficient can be found out by studying the instructions attached to the insulation or using data from the Internet (the first method will be more accurate).

Knowing this parameter, it is possible, by mathematical solutions, to calculate the required thickness of the insulation.

In addition to independent calculations, you can turn to professionals for help or use special online calculators. They are usually posted on the official websites of large manufacturers of heaters. In the windows of the calculator, it is enough to select the region of construction (or indicate the indicator of the total resistance of heat transfer), select the required thickness of the foundation and its type, the base material and the type of insulation used.

If it is necessary to calculate the thickness of the heat-insulating layer for the pile foundation in such calculators, it is usually necessary to put "0" in the column about the thickness of the foundation.

The result is displayed in millimeters.When receiving fractional numbers, they should be rounded up to integers and converted to centimeters.

When choosing polystyrene foam boards for slab or deeply buried tape bases, preference should be given to PSB-S-50 marking products. They can withstand high mechanical loads, which makes it possible to restrain soil swelling. Plates of the PSB-S-35 brand are suitable for insulating columnar and shallow strip foundations.

For information on how to insulate the foundation of a house with your own hands, see the next video.

The comment was sent successfully.