Pile-strip foundation: advantages and disadvantages, recommendations for construction

The need to ensure stability of capital structures on moving or swampy soils is the reason for the search for new foundation systems. Such is the pile-strip foundation, which combines the advantages of two types of foundations.

Peculiarities

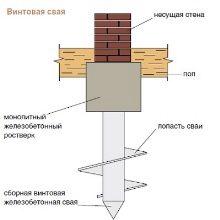

The pile-strip foundation is a strip base on supports (piles), due to which a stable structure with a high margin of safety is achieved. In most cases, such a foundation is created for large low-rise buildings on "problem" soils (clay, organic, uneven relief, water-saturated).

In other words, the strength of the structure is provided by a strip (usually shallow) foundation on which the walls rest, and strong adhesion to the soil is provided by piles driven below the freezing level of the soil.

This type of foundation is not designed for multi-storey construction. Usually, private houses of no more than 2 floors in height are erected on such a foundation using lightweight materials - wood, cellular concrete blocks (aerated concrete and foam blocks), hollow stone, as well as sandwich panels.

For the first time, the technology was applied in Finland, where mainly wooden houses are being built. That is why a combined foundation is optimal for wooden houses or frame structures. Heavier materials will require an increase in the number of bases, and sometimes search for other solutions.

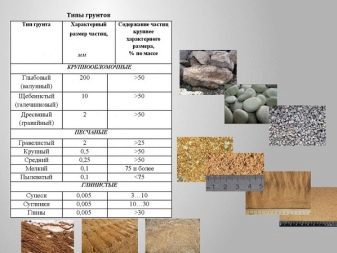

Most often, such a foundation is erected on floating clay, fine sandy soils, in swampy areas, poorly moisture-removing soils, as well as in areas with a height difference (no more than 2 m in level).

The pile depth is usually determined by the depth of the hard soil layers. A monolithic concrete foundation is poured into a formwork located in a trench 50-70 cm deep. Before starting work, they carry out a study of the soil and punching a test well. Based on the data obtained, a diagram of the occurrence of soil layers is drawn up.

The use of a strip foundation on piles can significantly increase the operational characteristics of the facility under construction.

Among the advantages of the system, some positions can be distinguished.

- The possibility of capital construction on "capricious" soils - where it is impossible to use a strip base. However, due to the heavy load of the facility, it will not be possible to use only piles.

- In the considered type of foundation, it is possible to reduce the sensitivity of the strip base to heaving soils and groundwater.

- The ability to protect the strip foundation from flooding, as well as transfer most of the weight of the foundation to harder soil layers to a depth of 1.5-2 m.

- Such a foundation is also suitable for strong soils subject to seasonal deformations.

- Faster construction speed than deep foundation construction.

- Possibility to get an object with a basement, which can serve as a useful or technical room.

- The availability of the use of materials used both for the organization of the foundation and for the construction of wall structures.

- Reducing the cost and labor intensity of the process in comparison with the organization of the strip foundation.

There are also disadvantages to such a foundation.

- The increase in the number of manual operations when pouring the foundation. This is due to the inability to use excavators and other equipment for digging trenches due to the driven piles.

- The inability to use the resulting semi-basement room as a full-fledged room (pool, rest room), as is possible when installing a strip foundation. This disadvantage can be leveled by digging a foundation pit, but the cost and labor intensity of the process increases. In addition, this approach is not possible on every type of soil, even in the presence of piles.

- The need for a thorough analysis of the soil, the preparation of voluminous design documentation. As a rule, this work is entrusted to specialists in order to avoid inaccuracies and errors in calculations.

- A rather limited choice of building materials for walls - this must necessarily be a lightweight structure (for example, made of wood, aerated concrete, hollow stone, frame house).

Device

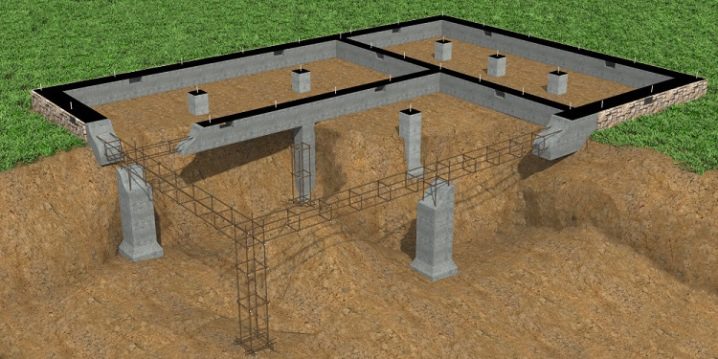

The load of the building on the ground is transmitted through a strip foundation installed around the perimeter of the object and under its load-bearing elements, and piles. Both the supports and the tape are reinforced with reinforcement. The installation of the first is carried out by the bored method or by the technology of pouring concrete with asbestos pipes installed in the wells. The bored method also involves preliminary drilling of wells into which the supports are immersed.

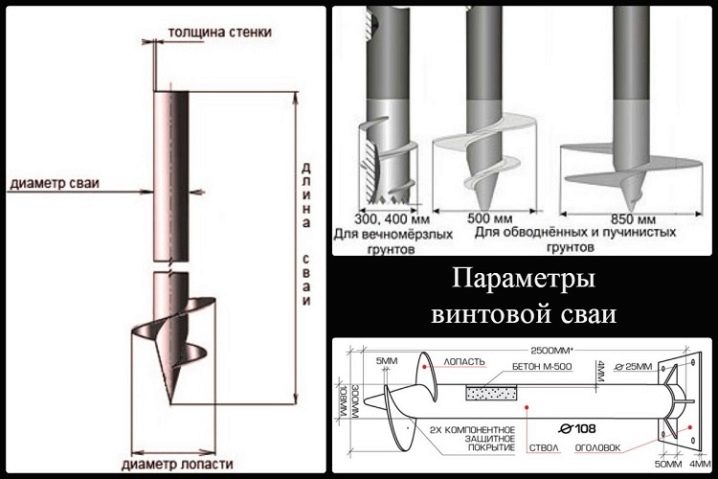

Screw piles with blades in the lower part of the support for screwing into the ground are also becoming widespread today. The popularity of the latter is due to the lack of the need for complex soil preparation.

If we are talking about screw piles up to 1.5 m, then they can be screwed independently, without the involvement of special equipment.

Driven piles are rarely used, since this method causes soil vibrations, which negatively affects the strength of the foundations of neighboring objects. In addition, this technology implies a high level of noise during operation.

Depending on the characteristics of the soil, piles and hanging counterparts are distinguished. The first option is characterized by the fact that the structure of the struts rests on solid soil layers, and the second - the structural elements are in a suspended state due to the friction force between the soil and the side walls of the supports.

Payment

At the stage of calculating materials, you should decide on the type and number of piles, their suitable length and diameter. This stage of work must be approached as responsibly as possible, since the strength and durability of the object depends on the accuracy of the calculation.

The determining factors in calculating the required amount of materials are the following items:

- foundation load, including wind load;

- the size of the object, the number of floors in it;

- features and technical characteristics of materials used for construction;

- soil features.

When calculating the number of piles, it is taken into account that they should be located at all corners of the object, as well as at the junction of the supporting wall structures. Supports are installed along the perimeter of the building in steps of 1-2 m.The exact distance depends on the chosen wall material: for surfaces made of cinder block and porous concrete bases, it is 1 m, for wooden or frame houses - 2 m.

The diameter of the supports depends on the number of storeys of the building and the materials used. For an object on one floor, screw supports with a diameter of at least 108 mm are required; for bored piles or asbestos pipes, this figure is 150 mm.

When using screw piles, you should choose models with a diameter of 300-400 mm for permafrost soils, 500-800 mm - for medium and heavily weathered, moisture-saturated soils.

It is important that they have an anti-corrosion coating.

The annexes - terraces and verandas - and heavy structures inside the building - stoves and fireplaces - require their own foundation, reinforced around the perimeter with supports. It is also necessary to install at least one pile on each side of the perimeter of the second (additional) foundation.

Mounting

Starting to make a strip foundation on piles, it is necessary to conduct geological surveys - observations and analysis of the soil in different seasons.Based on the data obtained, the required base load is calculated, the optimal type of piles, their size and diameter are selected.

If you decide to do the creation of the pile-strip base with your own hands, then the attached step-by-step instructions will simplify this process.

- On the cleaned area, markings are made for the foundation. The trench for the tape can be shallow - about 50 cm. The bottom of the trench is filled with sand or gravel, which will provide drainage of the concrete base and reduce the heaving of the soil. If we are talking about a large basement, then a foundation pit is pulled out.

- Drilling for piles is performed at the corners of the building, at the intersections of the structure, as well as along the entire perimeter of the building with a step of 2 m. The depth of the resulting wells should run 0.3-0.5 m lower than the level of soil freezing.

The borehole diameter should slightly exceed the diameter of the support used.

- In the lower part of the wells, a sand cushion with a height of 15-20 cm should be created. The poured sand is moistened and compacted well.

- Asbestos pipes are inserted into the wells, which are first filled with concrete by 30-40 cm, and then the pipes are raised by 20 cm. As a result of these manipulations, concrete flows out, forming a sole. Its function is to strengthen the structure, to ensure better adhesion of the supports to the ground.

- While the concrete is setting, the pipes are vertically aligned using a level.

- After the base of the pipe has solidified, its reinforcement is performed - a lattice made of steel rods tied with a metal wire is inserted into it.

The height of the grate must be greater than the height of the pipe so that the grate reaches the top of the base band.

- On the surface, a wooden formwork is made, reinforced at the corners with beams and reinforced from the inside with reinforcement. The latter consists of rods connected to each other by wire and forming a lattice. It is necessary to properly adhere to each other the reinforcement of the piles and strips - this guarantees the strength and solidity of the entire system.

- The next stage is the pouring of piles and formwork with concrete. At this stage, it is important to pour the mortar in such a way as to avoid the accumulation of air bubbles in the concrete. For this, deep vibrators are used, and in the absence of a device, you can use an ordinary rod, piercing the concrete surface in several places.

- The concrete surface is leveled and protected by a covering material from the effects of precipitation. In the process of concrete gaining strength, it is important to observe the temperature and humidity conditions. In hot weather, the surface should be moistened.

- After the concrete has set, the formwork is removed. Experts recommend immediately waterproofing the material, since it is hygroscopic. Moisture saturation leads to freezing and cracking of the foundation. In this case, you can use roll materials (roofing material, modern membrane films) or bitumen-polymer coating waterproofing. To improve adhesion to the waterproofing layer, the concrete surface is pre-treated with primers and antiseptics.

- The construction of the foundation is usually completed with its insulation, which allows to reduce heat loss in the house, to achieve a favorable microclimate. As a heater, polystyrene foam plates are usually used, glued to a special compound, or polyurethane foam, sprayed onto the surface of the foundation.

Advice

To achieve the smoothness of the outer walls of the tape allows the use of polyethylene. They are lined with the inside of the wooden formwork, after which concrete mortar is poured.

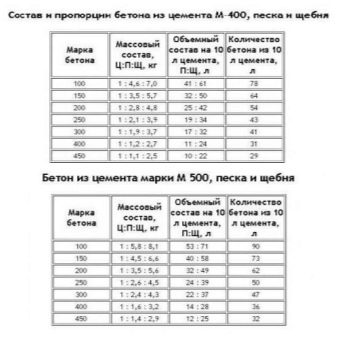

Feedback from users and advice from professionals allow us to conclude that the grout should be prepared from cement of a brand strength of at least M500. Less durable brands will not provide adequate reliability and solidity of the structure, have insufficient moisture and frost resistance.

A solution of 1 part of cement and 5 parts of sand and plasticizers is considered optimal.

When concreting, it is unacceptable for the solution to fall into the formwork from a height of more than 0.5-1 m. It is unacceptable to move the concrete inside the formwork using shovels - it is necessary to rearrange the mixer. Otherwise, the concrete will lose its properties, and there is a risk of displacement of the reinforcing mesh.

The formwork should be poured in one go. The maximum break in work should not be more than 2 hours - this is the only way to guarantee the solidity and integrity of the foundation.

In summer, to protect against dehydration, the foundation is covered with sawdust, burlap, which is periodically moistened for the first week. In winter, heating of the tape is necessary, for which a heating cable is laid along its entire length. It is left until the foundation gains final strength.

Comparison of the strength indicators of the reinforcement strapping with rods and welding allows us to conclude that the second method is preferable.

When introducing screw piles with your own hands, it is important to monitor their vertical position. Usually, two workers rotate with crowbars or levers, screwing in the base, and another one monitors the accuracy of the position of the element.

This work can be facilitated by preliminary drilling of a well, the diameter of which should be less than the support, and the depth - 0.5 m. This technology will ensure a strictly vertical position of the pile.

Finally, DIYers have adapted household power tools for driving piles. To do this, you will need a drill with a power of 1.5-2 kW, which is fastened to the pile by means of a special wrench-reducer, characterized by a gear ratio of 1/60. After starting, the drill rotates the pile, and the worker remains in control of the vertical.

Before purchasing piles, you should make sure that the anti-corrosion layer is present and reliable. This can be done by examining the documentation attached to the products. It is also recommended to try to scratch the surface of the piles with a coin edge or keys - ideally, this will not be possible.

The installation of piles can also be carried out at subzero temperatures. But this is possible only if the soil freezes no more than 1 m. When freezing to a great depth, special equipment should be used.

It is better to pour concrete in the warm season, since otherwise it is necessary to use special additives and heating the concrete.

You can learn how to build a strip foundation with your own hands from the following video.

The comment was sent successfully.