Pile foundation: features, pros and cons of the structure, installation

The foundation is an important component of most buildings. The service life and reliability of the house or outbuilding will depend on such a basis. There are several variations of foundations - from a simple strip to a strong pile. We will get to know the latter better, highlighting its pros and cons, as well as the nuances associated with installation work.

What it is?

Before proceeding to a detailed acquaintance with the pile foundation, you need to find out what it is.

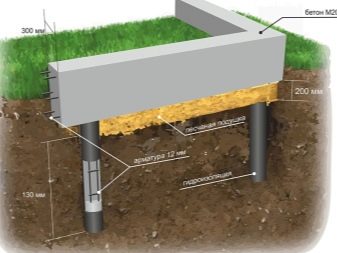

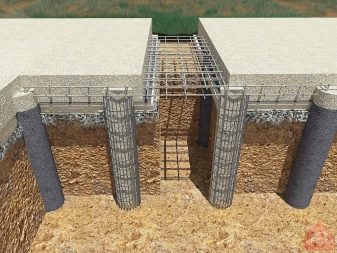

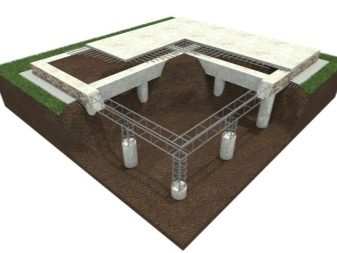

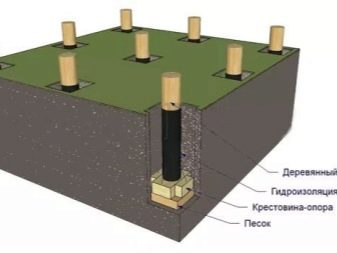

A similar base is piles immersed in the ground. These parts are connected to each other with reinforced concrete beams or a slab. In its pure form, such a foundation is not very common. This is due to the fact that it has a peculiar design that does not allow the load coming from the house to be distributed between the piles. As a rule, a pile foundation is erected during the construction of log or timber structures. It is permissible to refer to such a basis when erecting frame houses.

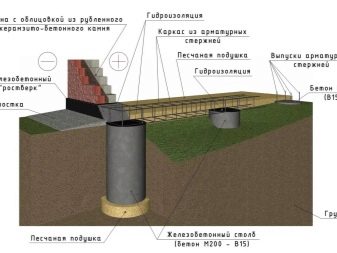

Today there is a more practical option for a pile foundation with a grillage. Such a foundation is devoid of many of the disadvantages inherent in conventional pile structures.

It can be used when building brick or block houses. In such structures, all supports are connected to each other using a special metal tape or concrete. This tape is called the grillage.

Peculiarities

As mentioned earlier, the foundation is one of the most important components in the construction of a private house or outbuilding. The pile foundation is quite reliable, the main thing is to choose the right variation so that your house has a strong support under it.

It is recommended to use such a basis if your house is located in an area with a predominance of weak, floating or slightly submerged soil.

So, the weak types of soil include:

- loam, clay in a fluid state;

- special loess-like soils that contain a lot of dust particles and a small amount of clay / calcareous elements;

- sandy-clayey types of soils, which are characterized by high water saturation;

- soil with impurities.

In addition, the pile foundation will be an excellent solution in deeply buried hard soils.

A distinctive feature of the pile foundation is that it is more economical when compared with shallow foundations. This is due to the fact that for the foundation with piles, it is not necessary to first dig a large pit. This is especially true when it comes to the construction of small houses with a modest weight.

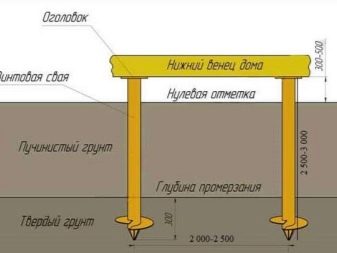

The main elements of a pile-type foundation are special strong rods that go deep into the ground. It is these details that are called piles. They are designed to evenly distribute all the loads exerted on the ground. A characteristic difference is such a component as a grillage, which is a beam, a strip base or a slab. These parts are designed to increase the design loads on the structure with piles.

The pile foundation is also distinguished by the fact that it usually does not take much time to erect it. This does not require large labor costs. So, for example, for the installation of a 3-meter pile with a diameter of 30 cm, it will only be necessary to dig 20 cubic meters. see land. For this, you can use a drill. It should be noted that today there are several variations of pile foundations. Of course, the most common are simple and grillage options.

Piles for such foundations are made from different materials. It can be wood, metal, or reinforced concrete. The choice of the optimal raw material depends on the loads that will be applied to the base. The choice of a suitable material is also influenced by the possibility of using a particular technology, the geological characteristics of the region in which the building is being carried out, as well as the nature and characteristics of the future house.

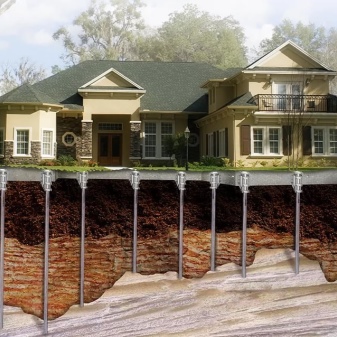

Structures with piles are used not only in private, but also in industrial construction. Such foundations are distinguished by the reduction of work on the construction of the basement of houses. There are times when these processes are completely excluded. Today, a pile-type foundation is most often used in the construction of cottages, as well as country and country houses.

Advantages and disadvantages

Despite not the greatest prevalence, pile foundations have many positive qualities.

If you decide to build such a foundation for a house, then you should familiarize yourself with them.

- The main advantage of the pile foundation, which is noted by many craftsmen, is the speed of its construction. This will take very little time.

- Such structures can be erected on problematic and soft soils. Not every type of foundation is suitable for such soils, therefore, a pile foundation in such conditions is an ideal option.

- To build a foundation on piles, you do not need to carry out a lot of earthwork. You don't have to dig a pit.

- This type of foundation is inexpensive, which also attracts many users planning to build a house.

- Having a pile foundation, you can make additional extensions to the house. If over time you want to expand the area of the dwelling or combine it with other structures (for example, with a garage or a bathhouse), then you can easily connect them to the previous foundation.

- The weight of the house is evenly distributed over the pile supports.

- Installation of such bases is quite simple, especially when compared with monolithic or simple tape options. For such a construction, it is not necessary to contact specialists - you can cope with all the work on your own, relying on simple instructions.

- Such bases are distinguished by durability. Their service life is over 30 years. Of course, if you carry out all the work correctly and use high-quality materials, this period can be much longer.

- Such a foundation can be built not only for private houses and cottages, but also for greenhouses, baths and other outbuildings.

- If you did everything correctly, the piles will not shrink over time.

- Before installing the piles directly, there is no need to prepare the ground - to remove debris or remove the top layer of soil (with the exception of concrete piles). Thanks to this feature, it takes a little time to build the foundation.

- The piles can be reused. Plus, they can be easily replaced if needed.

- It is permissible to build this type of foundation at any time of the year.

As you can see, pile foundation structures have a lot of positive aspects. However, such foundations are not perfect.

Let's get acquainted with the list of disadvantages that belong to foundations on piles:

- If you used metal piles, then they need to provide a high-quality protective layer. Otherwise, these parts may corrode, and this will take very little time.

- In the conditions of rocky places, it is simply not possible to build such a foundation.

- According to experts, during the construction of such a foundation, some problems may arise if other buildings are located nearby.

- If you are going to build such a foundation, then you will need to make the most accurate and scrupulous calculations of the depth of the supports.

- Drawing up a project for such a foundation can require considerable investment.

- When using concrete supports, it is important to take into account their impressive weight. Because of this, the installation process can be significantly complicated.

- Handmade piles cannot be used in the construction of such a foundation, despite their attractive cost. Otherwise, the structure may not last very long and cause a lot of inconvenience.

Standards

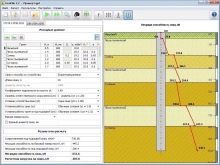

As with the construction of any other types of foundations, it is necessary to mount the base on piles in accordance with the requirements listed in the corresponding SNiP 2.02.03-85.

This document covers the joint venture (set of rules), as well as all the necessary information regarding the construction of a pile foundation:

- types of piles that can be used in the construction of the foundation;

- basic instructions regarding the calculation;

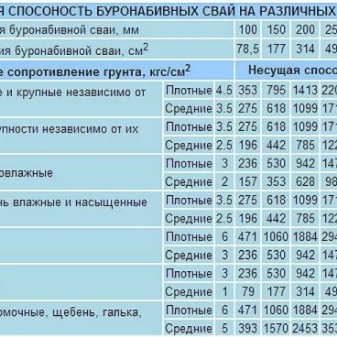

- calculation of the bearing capacity of pile supports;

- requirements for the installation of various types of pile supports (ram, drill, shell piles, piles filled with concrete and other types of supports);

- the document also includes taking into account the negative forces of friction of the soil on the lateral part of the piles;

- determination of the bearing capacity of pile elements;

- construction of foundations on piles;

- design features in various types of soil.

In addition, the document contains a number of recommended applicationscovering information on determining the shrinkage of a single pile, strip foundations and other important calculations.

Experts advise starting the construction of the pile foundation, relying on the information contained in the SNiP. So you will make not only a reliable and durable, but also a safe foundation that meets all the requirements.

Views

Pile foundations are different. The selection of a suitable design should be approached very responsibly, since the reliability and durability of the future house will depend on the perfect choice. Let's take a closer look at the most popular types of such structures and understand their features.

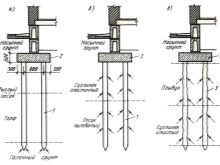

Zabivnoy

Rammed foundation piles are common. As a rule, these are reinforced concrete rods that are driven deep into the ground. The installation of such structures is based on the most accurate calculations of the distribution of the entire load of the house on the supports themselves. Such piles are driven into the ground until they penetrate into the most stable layer.

Such structures are often used in industrial construction. This is due to the fact that most often the installation work on the installation of piles is carried out using special equipment. It should be borne in mind that such foundations cannot always be used for the construction of ordinary houses or summer cottages, since it is simply unrealistic to put them on your own.

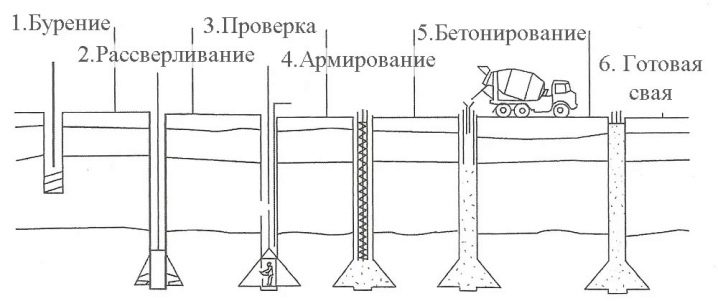

Bored

Before proceeding with the installation of the bored foundation, you must first drill wells. In the future, piles will be installed in them, as well as concrete mortar will be poured. Such installation work is most often referred to when erecting buildings of several floors.

The installation of bored piles is labor-intensive. To proceed to such work, you first need to do a lot of complex calculations. In addition, the cost of the work can cost a tidy sum due to its complexity. These disadvantages discourage many users from choosing such foundations.

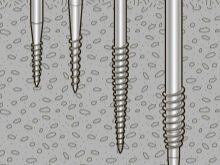

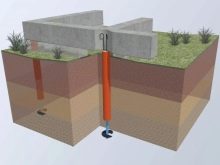

Screw

For country private houses and frame structures, just such bases are most often chosen. The installation of screw piles can be done by hand.Moreover, this process is inexpensive for the master and does not require much effort.

Steel pipes serve as the basis for the screw foundation. These components have a screw-type thread. Because of this feature, the piles are screwed into the soil, and with the help of special blades they are firmly held in it. If the soil on the site is excessively loose, then usually screw piles are used, which have a thread that stretches along the entire length of the pipe. Concrete is poured into steel elements to make the structure as strong, reliable and stable as possible.

The main advantage of such a base is the ease of its installation. You do not need to call a special technique for this.

For this reason, many people build similar types of foundations on their own. In addition, the screw-pile foundation can be installed in almost any type of soil. Moreover, you can start such work in any season.

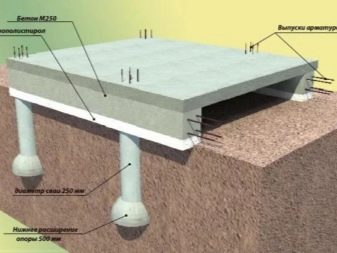

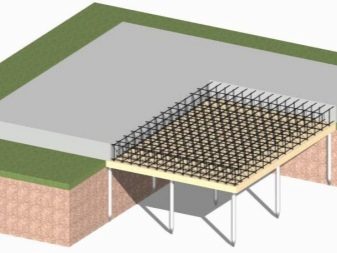

Pile-slab (SPF)

The pile-slab foundation is a revolutionary development in the construction industry. Currently, such structures are erected during the construction of high-rise buildings with a solid weight.

This type of foundation consists of the following basic elements:

- grillage;

- high-strength reinforced concrete piles with an increased level of stability.

The slab type of foundation with piles is simply necessary in such cases:

- if you are building a house (or outbuilding) on weak bulk soils;

- if there is a tight abutment to the foundations already existing on the site;

- if the construction of a house is planned in an area with high seismic activity;

- when it comes to building land with poor geology.

The main distinguishing characteristic of such a foundation is that it has the highest level of strength, which is very important for the foundation. Buildings built on such a structure serve for many years and are not afraid of negative external influences. Basically, such foundations are not afraid of vibration loads.

It should be borne in mind that for the installation of such a foundation, you must first prepare a place. Only after that do they start directly driving piles and pouring the slab.

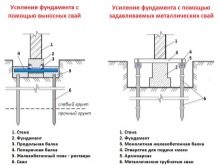

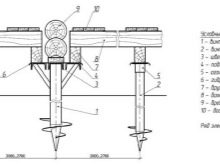

Monolithic with grillage

As mentioned above, a distinctive feature of the pile foundation is that with it, the entire load from the built house is placed on the piles. Often these details are combined with a grillage. There is a monolithic grillage, which is the upper area of the pile foundation, which serves as a dislocation of the load from the load-bearing elements of the structure.

A monolithic pile foundation with a grillage has the following advantages:

- it is possible to equip it on various types of soil (the exception is magmatic and sedimentary soil);

- when it is erected, a minimum amount of time is spent on earthwork;

- molding of this type of foundation is allowed to be done even in low temperatures;

- such bases are distinguished by excellent bearing capacity;

- the construction of such a foundation will be inexpensive.

The disadvantages of monolithic structures with a grillage include the fact that their installation cannot be done without special equipment and tools. In addition, during their construction, the owners will have to abandon the preparation of the insulated basement.

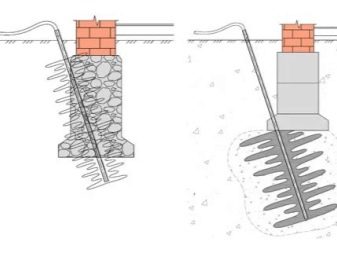

Buroinjection

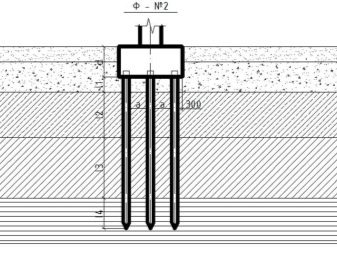

Today, for the construction of reliable and stable foundations, drilling-injection types of piles are often used. Such parts belong to the class of rammed supports. They are made by drilling wells and then filling them with a cement-sand or water-cement mixture using injection technology. To further strengthen the bearing capacity, these types of piles are often reinforced with iron pipes, reinforcing bars or reinforced frames. These elements are fixed in the well with a special metal structure in the form of a cylinder or a prism.

Bored piles are subdivided into the following types:

- piles-racks - these parts are installed as deep as possible into the underlying layers of hard rocks, while transferring the main load through the heel;

- hanging piles - such elements are mounted on the ground without a strong supporting layer and transfer the load to the ground with a lateral surface.

Pile-tape

The pile-strip foundation is one of the varieties of monolithic structures for heaving and weak soil types. The main feature of such a foundation is that, with it, the walls of the house will rest on a solid foundation with a slight deepening along the perimeter. As for reliable adhesion to solid soil layers, in this case it will be achieved thanks to piles installed below the freezing point.

The pile-strip foundation is good because it does not require large expenses, is erected quickly and perfectly resists heaving, as well as seasonal movements of the soil. The disadvantage of this design is that it will not be possible to equip a full-fledged basement with it. In addition, one must take into account the fact that buildings with heavy walls cannot be built on such a foundation.

You can make such a structure with your own hands. According to experts, even a beginner can handle such work.

Pile foundations differ not only in their structure, but also in the materials from which the piles are made. Let's consider in detail what are the distinctive characteristics of structures from different raw materials.

Materials for making piles

Wooden

Supports for a pile foundation are often made from wood. Typically, species such as spruce and pine are used for this. Expensive options from larch, oak and cedar are a little less common.

It should be borne in mind that, although wooden piles are flexible and easy to install, they are permissible only if we are talking about a structure of low weight. For example, it can be all sorts of outbuildings or wooden houses. The main advantage of wood for foundations is that it is easy to process. In addition, such material in many regions is considered affordable both in price and in prevalence.

However, foundation piles made of this environmentally friendly material also have serious disadvantages. For example, they cannot boast of good strength characteristics, which is why they cannot be used in the construction of large residential buildings. Also, the tree is prone to rotting, even if it is treated with a protective agent. Because of these disadvantages, wooden piles are rarely used today.

The wooden pile must have a diameter of at least 180 mm. The maximum length of solid-barrel parts usually does not exceed the mark of 16 m. If, however, a longer element is required during the construction of the foundation, then several trunks are specially spliced. As a result, the pile becomes longer and can reach 25 m.

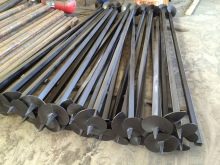

Steel

Steel piles can be of various configurations. Most often, there are elements that are a seamless tube, which has walls with a thickness of 8-12 mm. Special box-section supports can also be used. Similar parts are made from an I-beam.

To increase the bearing capacity, steel piles are often poured with concrete after installation work. Thanks to this, these parts become more stable and reliable.

Special screw piles are also made of steel. These products are quite popular nowadays, as they are easy to install and serve for many years. Screw piles outwardly resemble large drills or simple screw-wound pipes.

The large diameter steel piles are screwed using special equipment such as capstans.However, the supporting elements with a diameter of 100 mm can be put in place without the need for complicated technology. This can be done by two people using the gate.

Foundations, assembled from steel piles, are rightfully recognized as one of the strongest and most durable. Such structures are not subject to deformation. However, they are expensive, and over time they are subject to the formation of rust, which negatively affects the quality of the steel.

Reinforced concrete

Reinforced concrete types of foundation piles are the most common and in demand today. Such details are recognized as the most practical when viewed from the point of view of private construction. This is due to the fact that reinforced concrete can be used to make a support of almost any required diameter directly in the ground, without using complex specialized equipment.

Reinforced concrete piles can be purchased ready-made. In this case, they usually have a square or rectangular cross-section. Today, reinforced concrete screw supports are also found.

In the course of screwing, a strong metal core is placed in such parts, which is removed at the end of the installation work for screwing into the remaining pores.

Concrete piles are hollow and solid.

Specifications

The depth of the pile-type foundation depends on the distance at which the more durable soil layer is located. According to professional geologists, this layer can easily withstand the load created by the constructed building.

Pile foundations have a wide range of uses. These structures can be built in any soil (except rocky) and climatic zones. Thanks to this, the masters consider such designs to be universal.

It is permissible to mount a foundation with piles in the winter season, however, experts still recommend waiting for the warming before starting repair work.

As for the height of the foundation on the supports, it directly depends on the soil and other parameters: the personal preferences of the owners, the availability of running waters, the specific climatic zone.

The load affecting the pile foundation is divided into “squares”, so it is very important to do all the necessary calculations correctly. For this, it is recommended to contact a specialist.

Subtleties of the device

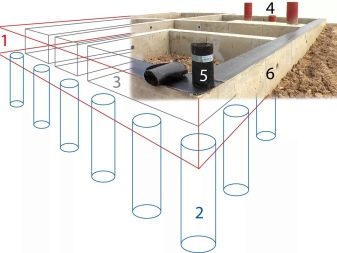

Before proceeding to the independent construction of a high-quality foundation on piles, you need to consider in detail how it works. Such a structure is a kind of support under the house (dacha, outbuilding, multi-storey building), which consists of separately spaced pile supports or a special pile field.

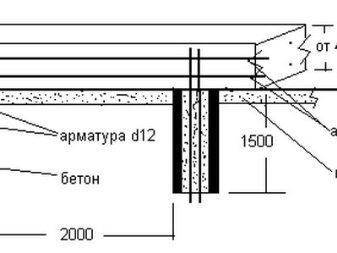

Most often, people choose high-strength and durable elements from a material such as reinforced concrete. However, you can also use non-reinforced concrete and rubble concrete (and other materials), which are cheaper and, in general, make the construction of the entire structure cheaper. To make concrete more durable, as well as to save it, it is necessary to reinforce the foundation structure on piles. As reinforcement, steel rods with a smooth surface or profiled parts are most often used. Foundation piles are always fixed at the corners of the future construction at the intersection of the internal load-bearing partitions with each other and with the external ceilings.

If there is a distance between the obligatory piles of 2 to 2.5 m (and sometimes more), then intermediate elements are mounted between them to close the holes.

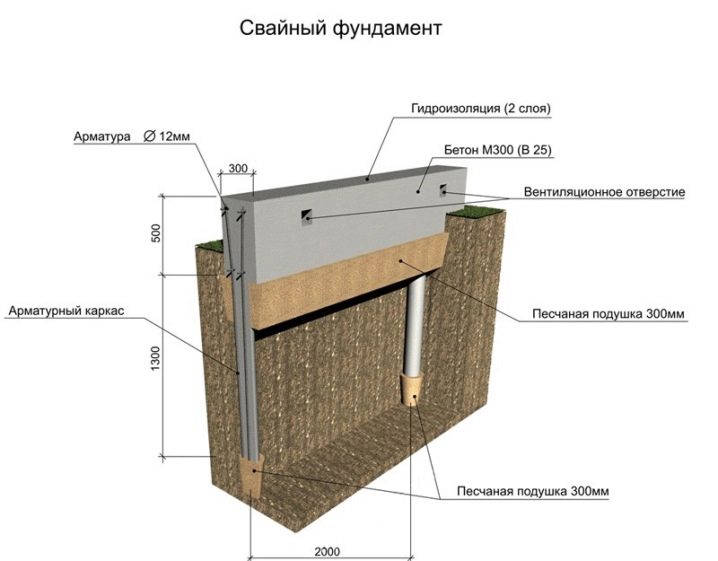

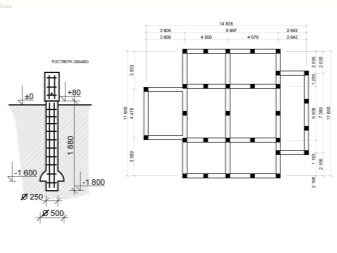

The entire structure usually consists of a sand cushion, a reinforcement cage, a concrete layer with ventilation holes, and a waterproofing layer.

Self-production

Most types of pile foundations can be made by hand.To do this, you must strictly adhere to the step-by-step instructions and use only high-quality materials / tools. Please note that none of the stages of the work can be neglected, otherwise the result may disappoint you.

Let's take a closer look at a step-by-step guide for building a foundation on piles using the example of a popular pile-tape structure.

Stages of work:

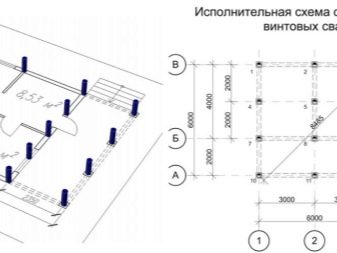

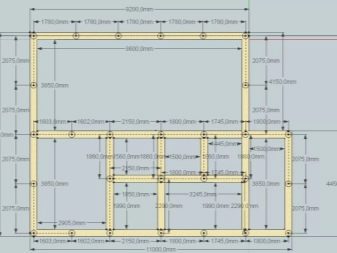

- First you need to draw up a project / drawing of the future construction and carry out all the necessary calculations. To make a high-quality and correct design, it is recommended to contact a specialist.

- First, you should divide the area into squares on which the construction of the foundation and the house itself is planned. To do this, you need to level the existing terrain, and it is also advisable to remove a layer of excess soil in order to level the field for further repair work.

- In the course of these works, it is necessary to delimit the outer perimeter of the building with the help of small wooden pegs and construction laces stretched between them. In addition, with the help of these elements, it is necessary to note the dimensions of the trench, which will be required for the grillage.

- After that, a trench should be dug under the tape. To do this, you can turn to the help of special equipment or carry out such work manually.

- The depth and width of the trench to be dug should be determined taking into account the engineering calculation. Also, it is necessary to take into account the formwork and backfilling of the soil. At this stage, the presence and level of the depth of the pit, intended for a basement or a special technical structure, is revealed.

- The next step is to drill wells for the installation of pile supports. Depending on the specific type of piles, appropriate holes are made in the soil. Sometimes they require additional sealing at the bottom, and sometimes vice versa, of a more modest size, as in the situation with driven structures. In this case, it is necessary to adhere to the step in accordance with the accepted calculation for the loads.

- The immersion of the piles into the prepared grooves is done either manually or using special equipment. At this stage, you should take into account the presence of a basement or technical room located below the point of the zero floor of the house.

- If you use pipes as piles, then their external partitions must be waterproofed with bitumen mastic or roofing material. As for the inner cavity of these parts, it is usually reinforced, and then poured with concrete.

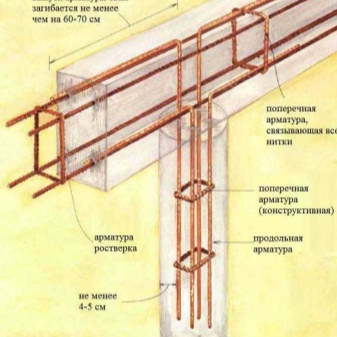

- This is followed by fixing the reinforced frame intended for the grillage. To provide a stronger and more reliable fastening, it is mated with the reinforcement protruding from the posts. After that, the frame is tightly fixed inside the trench using a soft knitting wire. Please note that the frame should in no case come into contact with the bottom of the dug trench and leave it outside.

- Now you need to build the formwork for the grillage. This process should be carried out in the same way as in the case of a simple strip foundation - it will be necessary to fix the shuttering panels at the edges of the trench.

- The walls of the wood shields must be covered with a special polyethylene tape. With such a detail, the formwork will last much longer and will not be subject to negative external influences.

- The next step is concreting. This work can be started only after all the required preparations. Experts recommend using concrete for this, which is produced in specialized factories, adhering to clear proportions. Usually, such materials are delivered to the construction site on special auto-mixers. Using sleeves or gutters, the mortar is poured into the prepared tape in one go. In this case, it is necessary to tamp the concrete using special vibrating devices.

- The next step is to dismantle the timber formwork and backfill. It is possible to remove wooden shields from the trench only after a few days (not earlier).

- The final step in foundation work is backfilling.

As you can see, for the construction of such a type of pile foundation, you do not need to have special education or rich experience. You can carry out all the stages yourself - there is nothing extremely difficult in this. The main thing is to adhere to the instructions and take a responsible attitude to the matter.

Of course, if certain doubts crept into you that you can prepare such a basis for building a house yourself, then it is better to entrust these works to professionals.

Bored

We will analyze step by step the process of installing another type of pile foundation - bored. Please note that the diameter of the drill required for such work must be at least 25 cm. It is advisable that its handle is type-setting, so that at any second you have the opportunity to make it a little longer or shorter.

The first stage in the installation of bored piles will be meticulous preparation, but you need to start it not from the site itself, but from a diagram / project on paper. You can take a territorial plan and put it on a separate sheet at the right scale. Mark on the drawing the exact dimensions of the future structure. Calculate the number of piles and determine their location based on the weight of the future construction.

Having made all the necessary calculations and having determined all the necessary parameters, you can proceed to the preparatory work on the foundation construction site. For this, any grass and other vegetation must be removed from the construction site.

Next, you need to mark the site. For this, pegs are hammered at specific points of the future structure. In this case, it is very important to take into account the gap between the centers of the pile supports - it will be equal to the total length of the wall, from which the width of the wall will be subtracted. Having placed the pegs in the corners, you need to measure the diagonals. If they are not the same, then 1 or more corners are made incorrectly.

After correctly setting all the necessary points between the pegs, you should pull a special construction cord, as in the case of a screw foundation. The gap from one rope to the next should be equal to the diameter of the piles that you will be installing. This must be done so that all foundation piles can be set up as quickly and easily as possible.

After completing the preparatory work, you can proceed directly to the construction of the pile foundation itself. To do this, first, recesses are drilled for bored pile supports at the points allocated for them. The drill must be positioned clearly in the center of the future hole so as not to collide with the displacement of the supports. To make cuts, you can use a drill, which has the function of extending the length if necessary. However, this solution has a disadvantage - in the case of manual drilling, you will have to expend a lot of effort, especially if you work in clay soil. However, using such equipment, you do not have to seek the help of special equipment.

From time to time, the drill will need to be lifted out of the hole in order to clear it of the earth. If the drilling process is difficult, then it is better to stock up on the assistant's proceeds. It is necessary to drill depressions under the supports to a depth that would be higher than the level of soil freezing. In this case, you do not have to worry about the stability of the structure during temperature changes.

For trouble-free control of the depth at which the pile structure will be placed, you can mark the drill handle. After completing the preparation of the recesses for the pile supports, you should proceed with the waterproofing of the structure. Since the soil keeps its shape well, the installation of additional formwork is not useful in this case. Instead of a similar design, it is permissible to use roofing material of a suitable brand - RKP-350.

For easier placement of roofing material in the inner part of the wells, reinforcement, as well as the future pouring of concrete solution there, it is necessary to make a branch pipe. This can be done from plywood circles corresponding to the diameter of the drilled holes.

The manufactured plywood device should be lowered into the drilled holes and well fixed. To do this, you can make your own device with a funnel and small sides. The plywood part will enable the roofing material to be securely held in place. In addition, this part will make the process of pouring concrete for the piles easier. Please note that in the future, the solution should be poured to the very top of the adapter. When the concrete reaches the desired point, the adapter can be removed and placed in the next depression.

It is very important to fill not only the underground part of the foundation piles, but also their upper module. Place it vertically. To achieve this, it is necessary to prepare a limiting structure of two rails, which must be installed at a distance corresponding to the diameter of the pile supports +1 cm. This component will provide a clearance of 5 cm on all sides.

Having made such a limiting structure, it is necessary to measure an equal distance in 2 other directions from the center point of the well in order to correctly position the formwork for the upper half. Please note that the hole at the top plays an important role in the plywood frame. It should coincide with the center of the borehole.

Next, you need an iron bar. A plumb line is hung in its middle and placed clearly above the center of the hole in the round timber of the plywood frame. In this position, measure the radius of the pile from the bar in 2 directions. Add 5mm to the dimension. Next, screw on the required point 2 wooden parts that will hold the formwork and prepare a concrete solution.

Prepare a metal frame for each support. Please note that its length should cover both the inner and outer half of the support and have a gap for ligation with reinforcement fixed in a concrete grillage. Lay concrete in the well under the piles with a layer of at least 10 cm. This way you will protect the reinforcement from corrosion.

After placing the reinforcement, fill the recess with a lightweight concrete mixture. The filling should be done until you reach the top of the hole made. Next, you should use a special vibrator to remove air pockets.

Next, the upper formwork is made of rolled roofing material. It needs to be securely fastened to hold the concrete. In this case, a steel mesh is used, wrapped around a layer of roofing material. Further, the pile support is completely filled with concrete. Please note that before installing the upper formwork, remove the metal support that attached the roofing material to the bottom.

Fully filling the recess, you need to very carefully use the vibrator, since in the case of a poorly connected metal mesh, the integrity of the structure may be violated. Before pouring the grillage, you need to wait a little for the piles to become more durable. Next, around the piles, you need to build a formwork made of wood or plywood.

Put a layer of waterproofing material in the formwork to make it easier to dismantle the shields in the future. For this, it is recommended to use high-density plastic wrap or roofing felt. In addition, it is allowed to coat the formwork with bitumen-based mastic. In this case, you need to make sure that the concrete does not ooze anywhere from the formwork. Strengthen the formwork with studs, but this must be done after the installation of the metal frame for reinforcement.

The frame must be tied up with the structure coming from the pile supports. Then the rods coming out of the piles are bent and fixed to the wire. Only after that is it permissible to proceed to filling. It is better to do it at a time so that the foundation does not turn out to be multi-layered.

It is more difficult to make such a kind of foundation than a strip one.In this case, it is very important to use the right tools, such as a quality pop-up drill. In addition, it is important to lay roofing material of a suitable brand, as well as concrete with the M300 marking.

Useful Tips

Many home craftsmen are wondering whether a blind area is needed when building a foundation on piles. The answer is simple: it is imperative that a residential building on such a basis be qualitatively protected from the negative effects of precipitation and groundwater.

Such a design must have the following characteristics:

- a slope of 3-5 degrees, so that the part of the structure adjacent to the basement half of the house is slightly (about 3-5 cm) above the outer section of the blind area;

- 15-25 cm wide more than the size of the eaves of a building on a pile foundation;

- a pillow thickness of 20-30 cm;

- the thickness of the decorative layer is 3-15 cm, but it must be borne in mind that if you are making a concrete structure, then its thickness should be about 13-15 cm, and if a tiled or stone one - 5-6 cm. In the case of asphalt, there will be enough 3-4 cm.

As mentioned earlier, timber piles can only be used in the construction of lightweight structures. In addition, such details are suitable if there is a high level of groundwater on the site.

Please note that steel supports are reusable. So, in the process of building a mobile building, such piles are not poured with concrete, and with further movement of the structure, they are pulled out in order to then fix it in a new place.

If you do not know which foundation is better to build for a light frame house, then you should turn to a screw pile foundation. In this case, this design will be the best solution.

Please note that when erecting a pile foundation, difficulties may arise due to some restrictions:

- When it comes to horizontally mobile soil. It includes planting and swelling types of soils. To determine the type of land, you need to turn to the help of laboratory research.

- When organizing a high-quality foundation on piles, problems often arise with the construction of a basement. The distance between the supports is important to fill, as is the case with columnar bases. These works will require additional expenses and efforts.

At the end of the foundation work, the soil is backfilled. For this, material is taken that was previously dug from a trench or a sand-gravel mixture, which must be additionally tamped. We must not forget that at this stage, additional insulation of the foundation tape is usually carried out (if we are talking about a pile-tape base). Most often, expanded polystyrene, planted on glue, is used for this purpose.

Experts recommend purchasing screw piles, which were coated with a reliable anti-corrosion compound during the manufacturing process. The manufacturer's warranty for such elements is 50 years, but in fact they last much longer.

Many consumers are wondering if the pile foundation is suitable for houses made of special SIP panels (SIP technology is a type of panel construction). For such structures, you can erect pile, and tape, and columnar types of foundation.

If your pile foundation has shrunk, then this indicates that it was erected incorrectly. In the case of competently performed installation work, such structures, as a rule, do not shrink.

If there is soil on your site that is prone to serious subsidence, then you better refuse the screw foundation, because in such conditions it may not be stable and durable enough.

It is very important for the self-erection of the pile foundation to correctly carry out all the necessary calculations. To do this, you need to calculate the mass of the future house, determine the reference area (based on weight and reliability factor), calculate the number of piles, select their cross-sectional area, and then compare the results with the reference area.

To build a foundation on piles, it is very important to purchase high-quality and reliable tools. It will be much easier to work with such devices. Do not skimp on materials such as roofing material, concrete, insulation and waterproofing.

Do not take on the work of self-construction of the pile foundation if you doubt your abilities. It is better to contact a trusted company in your city, the masters of which will do everything for you. Similar services are provided by many companies, for example, "SV-Fundament", "Unix Stroy", "SVF-Premium" and many others.

For pile foundations for one-story houses, see the next video.

The comment was sent successfully.