Shallow strip foundations: characteristics and subtleties of installation

The foundation is the main component of any structure, since it acts as its supporting structure, on which the durability and safety of operation depend. Recently, for the construction of frame houses, summer cottages and household facilities, they choose the installation of a shallow strip foundation.

It is ideal for all types of soil, is characterized by high strength, and the work on its laying can be easily done by hand.

Peculiarities

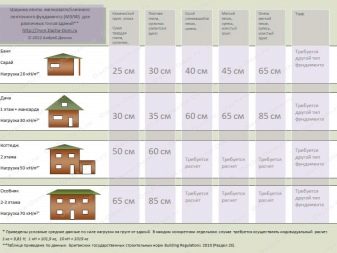

A shallow strip foundation is one of the modern types of foundations that are used in the construction of both one-story and two-story buildings made of foam block, expanded clay and wood. According to the SNiP regulations, such foundations are not recommended to be erected for buildings with a height of more than 2 floors that exceed an area of 100 m2.

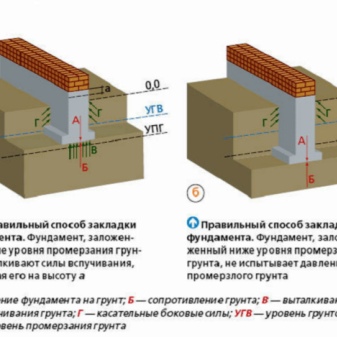

Such structures are considered a good option for buildings on clay, but during their design, the size of the structure must be taken into account. GOST also allows shallow strip foundations for unstable soil. Due to their design features, they can move with the soil, protecting the building from possible shrinkage and destruction, in this they are inferior to the columnar foundation.

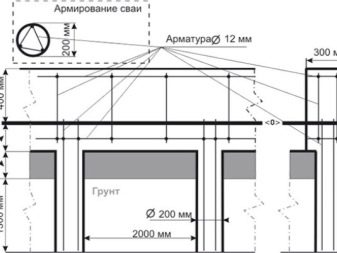

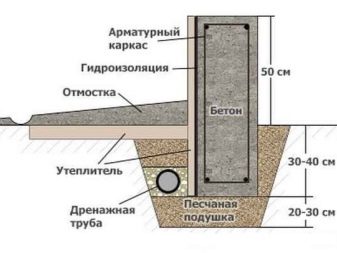

To make the base reliable and durable, it is installed on bored piles and monolithic reinforced concrete slabs are laid, which are deepened into the soil by 40-60 cm.First, the site is carefully leveled, then formwork is laid around the entire perimeter, the bottom is covered with sand and reinforcement is laid. For such a foundation, as a rule, a monolithic slab with a thickness of 15 to 35 cm is made, its dimensions depend on the dimensions of the future structure.

In addition, a shallow strip foundation has some features that must be taken into account when building it:

- the base is buried no deeper than 40 cm, and its width is made 10 cm more than the thickness of the walls;

- on heaving soil, it is imperative to create monolithic reinforced concrete structures that will help reduce the load from above and balance the heaving forces from below;

- the laying should be done on well-prepared and pre-compacted soil;

- with a high level of groundwater, it is necessary to provide for the laying of high-quality waterproofing and installation of a drainage system;

- a shallow foundation requires insulation from above, since a layer of thermal insulation will protect the base from temperature changes and will serve as an excellent source of heat.

Advantages and disadvantages

Today, during the construction of buildings, you can choose any type of foundation, but an unburied strip foundation is especially popular with developers, since it is considered the most reliable and has positive reviews when operating structures on heaving soils and on clay. It is also often installed in an area with a slope, where it is impossible to perform a recessed design option. Several characteristics are considered the main advantages of such a foundation.

- Simplicity of the device. Having even minimal skills, it is quite possible to lay the structure with your own hands without the involvement of lifting mechanisms and special equipment. Its construction usually takes several days.

- Durability. Observing all construction technologies and norms, the foundation will serve for more than 100 years.In this case, special attention should be paid to the choice of the grade of concrete and reinforcement.

- Possibility to design houses with a basement and a basement. With such a layout, the reinforced concrete tape will simultaneously serve as a supporting structure and walls for the basement.

- Minimum costs for building materials. For work, you only need reinforcement, concrete and ready-made wood panels for the manufacture of formwork.

As for the shortcomings, some of the features can be attributed to them.

- Labor intensity. For construction, it is necessary to first carry out earthwork, then make a reinforced mesh and pour everything with concrete. Therefore, in order to speed up the installation process, it is advisable to use the help of the wizards, but this will entail additional costs.

- Easy to build. In the case when the laying is carried out in winter, the concrete acquires its strength later, after 28 days. And this means that you will have to wait a month, since the base cannot be loaded.

- Lack of ability to construct tall and large buildings. Such a foundation is not suitable for houses, the construction of which is planned from heavy material.

- The need for additional styling waterproofing.

Payment

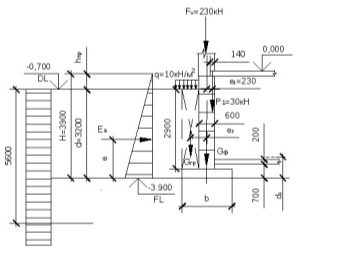

Before you start laying the foundation, you must complete the design and make accurate calculations. The complexity of calculations for a shallow strip base is to determine the hydrogeological characteristics of the soil on the site. Such studies are mandatory, since not only the depth of the foundation will depend on them, but also the height and width of the slabs will be determined.

In addition, in order to make the correct calculations, you need to know the main indicators.

- The material from which the construction of the building is planned. The strip foundation is suitable both for a house made of aerated concrete and for buildings made of foam blocks or timber, but it will differ in its structure. This is due to the different weight of the structure and its load on the base.

- Size and area of the sole. The future base must fully comply with the dimensions of the waterproofing material.

- External and lateral surface area.

- Dimensions of the diameter of the longitudinal reinforcement.

- Grade and volume of concrete solution. The mass of concrete will depend on the average density of the mortar.

In order to calculate the depth of the laying, it is necessary first of all to determine the bearing capacity of the soil at the construction site and the parameters of the sole of the tape, which can be monolithic or consist of blocks. Then the total load on the foundation should be calculated, taking into account the weight of the ceiling slabs, door structures and finishing material.

It is also important to investigate the depth of soil freezing. If it is from 1 to 1.5 m, then the laying is carried out at a depth of at least 0.75 m, when freezing to more than 2.5 m, the base is buried to a depth exceeding 1 m.

Materials (edit)

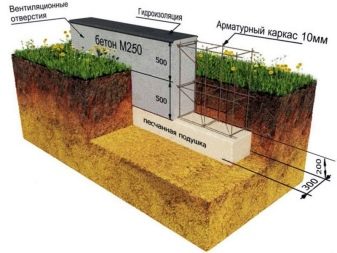

Installation of a base for a building involves the use of high-quality building materials, and a shallow strip foundation is no exception. It is erected from a reinforced concrete frame on a sand cushion, while the layout can be either monolithic or consist of blocks.

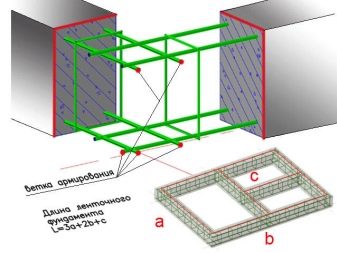

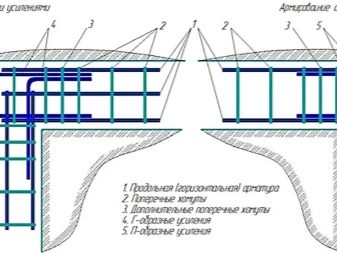

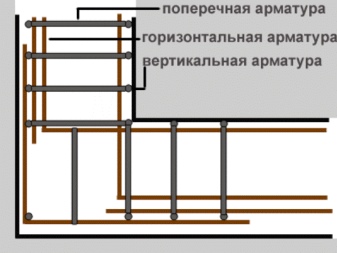

For the reinforcement of the base, steel rods are used, which, depending on their characteristics, are divided into classes A-I, A-II, A-III. In addition to rods, reinforcing cages, rods and meshes are also laid in the thickness of the concrete. The mesh and the frame is a structure made of transverse and longitudinal rods that are attached to each other.

The reinforcement scheme is selected in accordance with the design features, and it depends on the loads on the foundation. For the installation of a shallow base, steel rods with a diameter of 10 to 16 mm are well suited, they perfectly withstand loads and stretch. Transverse reinforcement, as a rule, is performed using smooth wire with a diameter of 4-5 mm.

Knitting wire is also used as an auxiliary material, it is used to fix the rods in the manufacture of the mesh and frame.

To increase the service life of the foundation, all reinforcement elements must be protected from external factors; for this, a gap of 30 mm is left between the edges of the rods and the concrete.

In addition to the protective layer, the reinforcement is additionally placed on the supports, so both special supports sold in stores and pieces of steel or scrap metal can be useful for construction. During the laying of the base, the manufacture of formwork is provided; it can be purchased both ready-made and independently knocked down from wooden planks.

For filling the air cushion, medium-sized sand is used, and the filling is performed with concrete mortar of various brands. In this case, concreting is best done with a high-class mortar, grade M100 and higher.

Device stages

The technology of installing a shallow foundation is not particularly difficult, so it is quite possible to do all the work with your own hands. Before you start laying the foundation, you need to draw up a project, as well as an action plan, in which all the activities "from A to Z" are written. In order for the foundation to reliably serve for more than a dozen years, it is important to pay attention to such points as insulation, waterproofing and the frequency of fastening the reinforcement.

It is best if the foundation is monolithic.

It is also important to make a preliminary geodetic assessment of the soil, which will determine the level of groundwater, soil composition and the depth of freezing. The choice of the type of foundation and the depth of its laying will depend on these parameters. In the event that a budget construction option is planned, then it is enough just to drill several holes in different places of the site and independently study the soil.

The soil, in which there is an admixture of clay, easily rolls into a ball, but if it cracks during formation, then the soil consists of loam. Sandy soil cannot be rolled into a ball, as it will crumble in your hands.

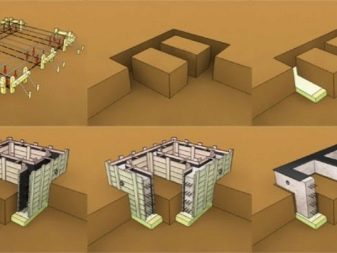

After the composition of the soil has been determined, you can start building the foundation. As a rule, step-by-step instructions include the following steps:

- calculation of the section of reinforcement, the width of the tape and drawing up a reinforcement scheme;

- making a foundation pit or a trench for buildings without a basement;

- laying the drainage system and thermal insulation;

- installation of formwork and fastening of reinforcement;

- pouring with concrete and installing waterproofing after stripping.

The completion of the foundation is considered to be the insulation of the blind area, for this it is lined with a special material that is resistant to moisture. If all points of the instructions are performed correctly, in compliance with the technologies and construction standards, then the resulting shallow strip foundation will not only become a reliable basis for the structure, but will also last a long time, protecting the structure from external influences.

Excavation

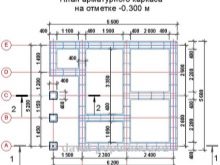

The construction of the foundation should begin with the preliminary preparation of the land plot, it is thoroughly cleaned of debris, plants and trees, and the fertile soil layer is removed. Then the markings are made and all measurements specified in the building design are transferred to the working site. For this, pegs and a rope are used. First of all, the facade walls of the building are marked, then two other walls are placed perpendicular to them.

At this stage, it is important to control the evenness of the diagonals; at the end of the marking, a rectangle is obtained that compares all the diagonals.

Beacons are hammered in the corners of the future structure, keeping a distance of 1 m between them. The next step is to install a wooden blind area over which the ropes will stretch. Some craftsmen simply apply the dimensions of the foundation to the ground using a lime mortar. Then a trench is dug, its depth should correspond to the thickness of the sand cushion and tape.

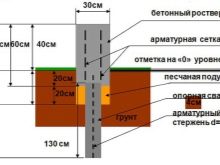

Since the thickness of the sand cushion usually does not exceed 20 cm, a trench 0.6-0.8 m wide and 0.5 m deep is made for a shallow foundation.

In the event that the project provides for the construction of heavy structures with stairs, a porch and a stove, then it is recommended to dig a pit. To make a pillow with a thickness of 30 to 50 cm, crushed stone and sand are used, the most common option is a pillow consisting of two layers: 20 cm of sand and 20 cm of crushed stone. For dusty soil, it is necessary to additionally put geotextiles in the trench.

The pillow is covered in layers: first of all, a layer of sand is evenly distributed, it is tamped well, moistened with water, then gravel is poured and tamped. The pillow should be placed strictly horizontally and covered with roofing material waterproofing on top.

Formwork

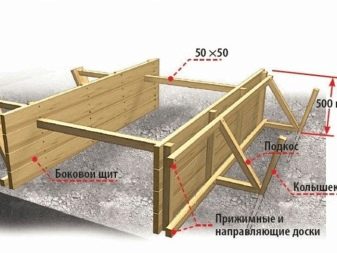

An equally important point when laying the foundation is the assembly of the formwork. To make it, use such shield materials as sheets of OSB, plywood or boards with a thickness of at least 5 cm. In this case, the boards should be knocked into shields. The formwork must be calculated in such a way that it turns out to be several centimeters above the future concrete level. As for the height of the tape, it is made equal to or less than the depth of the foundation, as a rule, it is 4 times the width of the tape.

The prepared shields are attached to each other with nails or self-tapping screws, after which they are additionally propped up with pegs. It is worth paying attention to the fact that all fasteners do not stick out and go out into the formwork. If you ignore this, then after pouring they will end up in concrete and can provoke the appearance of cracks or chips.

The formwork of a shallow strip foundation is also additionally reinforced with struts made of a bar with a section of 5 cm, such supports are placed externally at a distance of 0.5 m.

In addition, holes for communications must be prepared in advance in the formwork and pipes must be inserted. The inner part of the structure is covered with polyethylene, it will strengthen waterproofing and reduce adhesion to concrete.

It is also allowed to use a non-removable formwork made of extruded polystyrene foam.

Reinforcement

The device of this type of foundation includes mandatory reinforcement. The reinforcement can be both knitted with wire and welding, but the latter option is not recommended for connecting metal rods, since corrosion will appear at the attachment points over time. For the installation of the frame, a minimum number of rods is required, at least 4 pieces.

For longitudinal reinforcement, ribbed material of class AII or AIII should be used. Moreover, the longer the rods are, the better the frame will turn out, since the joints reduce the strength of the structure.

The transverse parts of the frame are assembled from smooth and thinner reinforcement with a diameter of 6 to 8 mm. To install a shallow base, two reinforcing belts, consisting of only 4 longitudinal rods, will be sufficient. It is important that the edges of the reinforcement move 5 cm away from the foundation, and between the vertical fasteners the step is at least 30-40 cm.

A crucial moment in the work is the manufacture of the corners of the frame: the rods must be bent in such a way that the entrance to the other wall is at least 40 mm from the diameter of the rods. In this case, the distance between the corners formed by the vertical bridges should be half the distance in the wall.

Fill

Completion of work during the installation of the foundation is the pouring of concrete mortar. Experts recommend for this to use factory concrete of a grade not lower than M250. If the solution will be made independently, then you should first prepare the concrete mixer, since it will be difficult to do it manually. The base must be poured with a solution immediately, for this it is evenly distributed over the entire surface and tamped.Each layer of filling should be carefully leveled according to the mark on the formwork.

Experienced craftsmen, who have made more than one hundred foundations, advise sprinkling the concrete with dry cement at the end of the pouring, this will improve its quality and the top layer will set faster.

As a rule, one month is allotted for the complete solidification of the base, after which construction work can be continued.

Major mistakes

Since the foundation is the main component of any structure, it must be laid correctly, especially for a shallow strip base, which is installed on loose soils and clay soils. Any mistake made during its construction can nullify all construction work. When making a foundation yourself, inexperienced craftsmen make several common mistakes.

- Construction begins without calculating the basic dimensions and load on the foundation.

- The base is poured directly into the ground, without sprinkling and making a sand cushion. As a result, in the winter season, the soil will freeze to the concrete, drag and lift up the tape, as a result of which the foundation will begin to heave under the influence of the frost force, and the basement floor will crack. This is especially true when there is no insulation.

- Choose the number of bars and the diameter of the reinforcement at your discretion. This is unacceptable, as the foundation reinforcement will be incorrect.

- Construction is carried out in more than one season. The entire cycle of work should be distributed so that the laying of the base, laying out the walls and insulation of the blind area are completed before the onset of cold weather.

In addition, it is considered a big mistake to protect the concrete base with a film. Don't close it. The poured solution must have access to ventilation.

For how to make a shallow strip foundation with your own hands, see the next video.

The comment was sent successfully.