Enamel NTs-132: properties and characteristics

A large number of enamels and paints are used to protect and give various decorative characteristics to the surface in construction and repair. Modern developments lead to a large selection of paints and varnishes with a variety of properties. Enamel NTs-132 has been known on the market for a long time, but at the same time it does not lose popularity. The answer to the question why it is still in demand is contained in this article.

Peculiarities

Enamel NTs-132 has been produced since the 70s of the last century, and it is hard to believe that currently no paint and varnish compositions have been invented that would surpass it in their characteristics. Unlike paints, enamels, after complete hardening, form a smooth, uniform layer that protects the surface from various influences.

Initially, the main difference between enamel and paint was the type of thinning liquid. For enamel paints and varnishes, volatile organic compounds were used. In the case of paint, it could be drying oils or ordinary water. Over time, more and more water-dispersible enamels and paintwork materials based on acrylic began to appear.

The letters NTs indicate that this enamel belongs to the group of nitrocellulose, that is, paintwork materials made on the basis of nitrocellulose. It is a white fibrous structure, loose in appearance, reminiscent of ordinary cellulose and obtained from it using nitrogen treatment.

The composition of NTs-132 includes volatile and non-volatile parts. The first group includes alkyd resins (No. 188 according to the classification of resins), colloxylin-nitrocellulose with a nitrogen content of 10.7-12.2%, plasticizing additives and pigmenting particles. The non-volatile group is different for different types of enamels. It includes either 40% toluene, butyl or ethyl alcohol, about 15% active high-boiling solvents and slightly less low-boiling ones. In the second case, xylene is added instead of toluene, and the solvents reach 30%. An anti-flotation and fire retardant additive can be added to enhance decorative properties, smooth surface distribution.

The compositions are pigmented with the help of special pastes, which are kneaded in devices for grinding them.

Manufacturers pay attention to the exceptional resistance of NTs-132 enamel to various influences.

In addition, such positive qualities are noted:

- high strength and wear resistance;

- elastic structure is suitable for using any shape and shape of surfaces;

- water resistance allows the use of enamel in structures with high humidity and outdoors;

- ease of care for surfaces covered with paintwork materials - can be washed with any household products;

- a layer of enamel can be sanded and polished to give a glossy shine, which will further affect the decorative appearance of products;

- the coating does not fade in the sun and does not lend itself to ultraviolet radiation;

- withstands strong temperature fluctuations;

- the material is economical and has a low price;

- long service life. When processing the surface with enamel in two layers in moderate climatic conditions, the coating can retain its decorative and quality features for up to two years.

Views

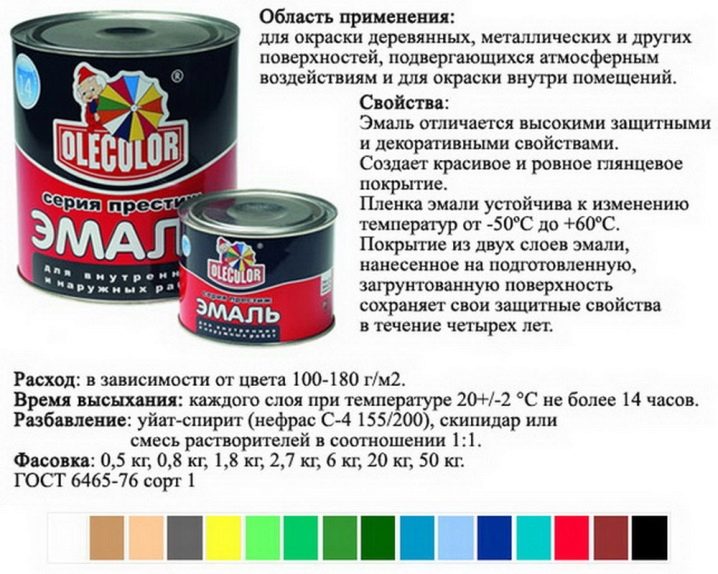

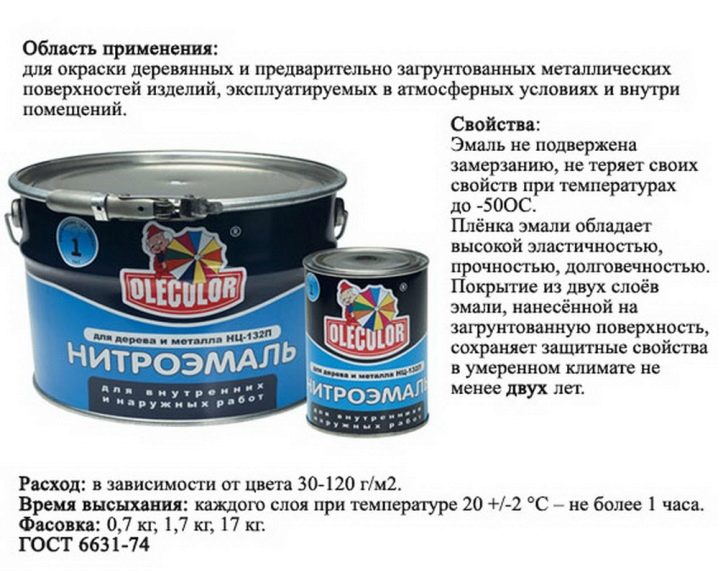

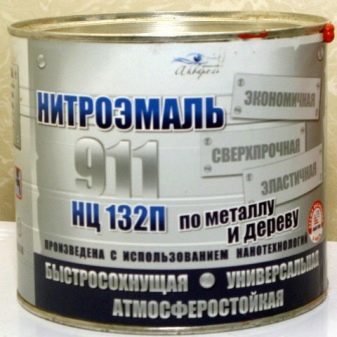

Types and technical parameters of NTs-132 enamel are regulated by GOST 6631-74.

There are two types of paintwork materials:

- NTs-132 "K" designed to be applied with a brush and has a certain consistency, but it can be thinned with a thinner to a thinner consistency;

- NTs-132 "P" - liquid form suitable for spraying with a spray bottle.

Enamel specifications.

- The ambient air temperature for the use of paintwork materials should be in the range from -12 to +60 C.

- 120 minutes after application, the surface treated with NC-132 may acquire a slight stickiness. Full use is possible one day after staining.

- The film layer formed by the enamel after hardening is characterized by excellent smoothness, absence of streaks, spots, bumps and depressions.

- The hardness index is not less than 0.15 cu. e. It is determined by a special pendulum device TML.

- The U-1 device allows you to measure the impact strength of the layer - not less than 50 cu. e.

- The gloss of the composition is in the range of 40-55%.

- The mass fraction of volatile substances can be easily determined by the color of the liquid. For black enamels, it is the lowest (22-28%), in other shades more than 29% of volatile compositions.

- The shelf life when kept in a sealed package without violating storage conditions is set at 1 year.

Enamels NTs-132 are produced in a variety of convenient formats in cans, ranging from 0.7 kg, 1 kg, 1.7 kg and up to large barrels for industrial facilities in 17, 25 kg and more.

Colors

The color scheme is also regulated by GOST. The choice of shades is wide enough and allows you to choose the right color for any type of finish. Light shades are represented by standard white, two types of light gray and cream, light beige.

The dark range includes dark blue-green, tobacco, dark gray, gray-blue, gray-green, protective, black. If you need to finish surfaces more brightly, shades are suitable: red, red-brown, orange-brown, golden-yellow.

Natural colors are represented by calm light greenish-yellow, pistachio, light gray-green, pale green, gray-blue. If you need a different shade, it is also possible to make individual production in accordance with the RAL catalog.

Consumption

Enamels NTs-132 go on sale in a ready-to-use liquid form. After opening the can, you can start finishing work immediately with a spray gun, brushes or rollers. If, nevertheless, there is a need to dilute the product, this is done using solvents.

For enamel of NTs-132K type it is necessary to use composition 649, and for NTs-132P - 646 version in accordance with GOST 18188. In any case, the composition in a freshly opened can must be stirred immediately to give it a uniform consistency. The time to achieve hardness and dryness is about 2 hours at a temperature of 20 C. If the thermometer readings in the room or outside are different, then the final result can be achieved at different times.

It is customary to apply two or more layers of paintwork materials on the surface to achieve the best coverage. Enamel consumption is determined by the characteristics of the covering power of the product. This indicator indicates how many grams of the composition should be applied per 1 m2. The color of the composition affects the consumption most of all. Dark shades: black and dark blue-green require 30 g / m2 of enamel, and light shades - white and cream - 100 g / m2.

To reduce the consumption of the composition, special attention should be paid to surface preparation before painting. Metal bases must be cleaned of corrosion, dirt, rusty marks.

Wood surfaces should be thoroughly dried and sanded for better adhesion. To reduce the absorbency of natural material, it is better to use a primer or a thin layer of highly diluted enamel of the same type. Primers are suitable for AK-070, GF-021, FL-03K, VL-02.

If there are grease spots on the surface, it is imperative to treat them with special compounds. If the base was covered with oily paints, they must first be removed without a trace.

Scope of application

Although enamel NTs-132 belongs to toxic and fire hazardous materials, it is widely used due to its protective and elastic properties.Wooden products, structures located in a harsh climate, high humidity will perfectly preserve their original appearance. Metal surfaces and concrete bases will be reliably protected from corrosion. This is applicable both in the domestic environment and in the processing of materials in industrial production.

In households, due to its excellent decorative properties, paintwork materials can be used to paint furniture, walls and decor items. Facades of buildings and metal fences due to low consumption are also profitable to process NTs-132. But the harmful substances emitted when working with nitro enamel forced some countries of the world to restrict the use of this product and even ban it completely.

Precautionary measures

Due to the above characteristics and toxicity when using enamels, certain recommendations must be followed. It is better to store materials in specially designated areas away from flammable materials and direct sunlight. When applying the composition, it is necessary to use rubber gloves and a respiratory mask to prevent vapors from entering the lungs. Protection should be provided for the eyes in the form of special glasses. The use of protective clothing is also required. It is better to carry out work in places with the possibility of ventilation. Painting should be carried out in the absence of open flames.

At the end of the work, wash your hands and face with soap and water.

Manufacturers

Plants producing enamel NTs-132 and other paintwork materials are located in many cities of Russia.

Long and widely known NPO Ladoga, which has two production facilities - in Omsk and in the Crimea. The Novosibirsk plant "Kolorit" has developed a system of discounts for regular customers and a dealer program to facilitate the sale of its high-quality and budget products.

LLC "Belkolor" popular with the average consumer. Buyers note the excellent covering ability, bright colors and fast drying of the NTs-132 enamel from this manufacturer. The Belgorod enterprise has a twenty-year history, it has grown from a small workshop into an international brand with premium lines, which are not inferior in quality to foreign counterparts.

Good reviews are getting LKM firm "Tex"... The availability of products in a variety of hardware stores, combined with low price tags, makes it a worthy competitor in the paints and varnishes market. The manufacturer is ready to confirm the quality of its products with many certificates.

Company group "Lacra" manufactures its products in Canada, Switzerland, Poland and other European countries. Tempting prices are due to the availability of production facilities in our country. The enamels maintain the western level of quality characteristics.

LLC "Continental" is a rapidly developing young company in the construction market in Russia. But high quality standards, dynamic development and increasing production capacity in combination with a huge range of products allowed them to occupy their niche in the paint and varnish sales market. Enamels of the Krafor brand, produced by this manufacturer, are positioned as corresponding to GOST and sanitary and epidemiological standards. The factories of the company are located in many cities of the central part of Russia, in Udmurtia, as well as in the Czech Republic, Slovakia and Serbia.

For an overview of NTs-132 enamel, see the next video.

The comment was sent successfully.