Features of hammer enamel

If you need a reliable coating for metal, which will give the surface an interesting texture and at the same time protect it from external negative influences, opt for hammer enamel. Its feature is also the fact that the paint can be applied directly to rust without preliminary preparation of the metal, it is as easy to use as possible.

What is hammer enamel

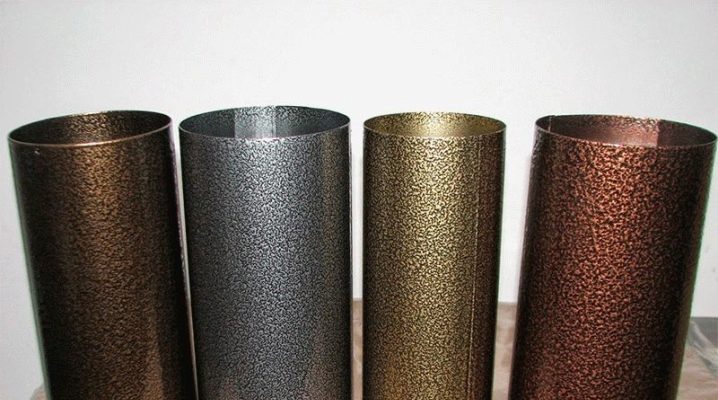

Hammer enamel (sometimes called "blacksmith paint") is a decorative coating for metal. The name "hammer" was attached to this paint, because after processing it, the surface looks like a chasing with potholes and irregularities, made with a hammer. Or it can be a volumetric stain. Think of antique handmade metal jugs - they look like a similar metallic effect. If you look at the orange peel, you can see that the hammer paint forms similar bumps.

This enamel appeared as a necessary material for painting equipment in factories and laboratories. And later it began to be used for other purposes due to its resistance to external influences. The high density of hammer enamel is provided by metallic powder. Also, modern hammer dyes add color pigments of all kinds of shades, fine-grained glass and aluminum flakes, which improve the texture of the enamel.

Depending on the desired result, several layers of paint can be applied at once. Another feature of hammer enamel is that it can mask such imperfections on a metal surface as rust. For example, Hammerite Hammered enamel with silicone additive forms an ideal wear-resistant anti-corrosion coating on a metal surface.

Benefits of hammer enamel

High-quality hammer enamel for metal has the following advantages:

- resistance to temperature extremes and other climatic influences - such a coating does not deform at temperatures up to 80C;

- no need to remove rust before painting;

- ease of staining;

- dries quickly (usually after 2 hours);

- resistance to vibration, which is why hammer enamel is used in factories and enterprises, as well as in garages;

- UV resistance, so the paint does not fade for many years;

- anti-corrosion protection for up to 8 years;

- helps to hide many defects in the metal surface (for example, dents);

- safety (no toxic substances are released after drying);

- the ability to use a brush or aerosol when applying;

- you can use enamel for both external and internal work;

- an extensive selection of shades;

- preservation of the original appearance for several years;

- durable enamel coating repels dirt.

Areas of application of hammer enamel

The effectiveness and other properties of hammer enamel depend on the type of substance in it. Therefore, first, decide for painting which metal elements the composition will be used:

- pipes;

- boilers;

- doors;

- fences;

- stairs;

- radiators;

- technology;

- furniture;

- tools;

- gate;

- industrial equipment;

- working tool;

- electrical panels;

- drainage elements;

- building structures;

- safes and metal cabinets;

- office furniture;

- agricultural machines;

- other metal decorative elements both outside and inside the premises;

- products from hard plastic, glass and tiles.

Types and manufacturers of hammer enamel

There are several types of such paint:

- ML 165 type suitable for decorating a non-greasy surface. The advantages of this paint are durability and heat resistance (it can withstand heat up to 130 C). The disadvantage is the ability to emit toxic fumes when applied.

- Hammerite Rust Enamel - an expensive but very effective pleasure. This English-made paint will not only mask imperfections on the metal, but also protect the surface from oxidation. Thanks to a special technology with the addition of wax, Hammerite enamel will provide protection against moisture and corrosion for up to 8 years. In addition, this paint contains silicone, which prevents the penetration of external contaminants and household chemicals. Hammerite paints and varnishes are quick-drying and can be used on metal without prior preparation.

- Enamel EP-1323ME suitable as a paint-primer for metal. This type of paint is recommended for elements of cars, forklifts, as well as doors and all kinds of fences. You can also use this dye over rust.

- Enamel NTs-221 is inexpensive, but its protective properties are quite high. This "budget" type of paint can be used exclusively indoors, as it is not capable of performing a protective function and has purely decorative properties. In no case do not apply this enamel over rust, and the heat resistance index is low here.

- Hammer enamel "Molotex" used in several areas at once - on rust, as decorative enamel or anti-corrosion primer. The product contains persistent pigments and synthetic varnishes, which ideally hide the defects of the painted products and protect the surface from external influences. Available colors of this enamel: black, silver, dark green, brown, white and dark blue.

- Primer-enamel for rust 3in1 Dali used for processing metal affected by pitting or continuous corrosion. It is used for new or previously painted surfaces made of stainless steel, cast iron, non-ferrous and galvanized metals, as well as wooden surfaces with a moisture content of less than 20%.

Hammer enamel for car

If initially hammer enamel was used exclusively in production, then soon car owners were also interested in it. And all this is due to the high technical characteristics and stability of the composition to mechanical movements, vibrations and temperature extremes. The special hammer paint for cars adheres to any surface and is especially resistant to impact and corrosion. The only drawback can be called instability to the effects of brake fluid, but engine oil does not pose a problem for such a coating. Automotive companies now offer a wide variety of hammer paint shades.

Tool selection

After preliminary cleaning and surface preparation, you should opt for a specific painting tool.

You can paint the surface with:

- brushes;

- spray gun;

- aerosols;

- roller.

An aerosol can is suitable for covering a small area and flat surface. Uneven products, where there are many welds and curved parts (for example, curly lattices), it is better to paint over with a brush with natural bristles. And for large surfaces (gates, roofs, doors), prepare a spray gun and a roller.

Testimonials and advice from professionals

Professionals in their reviews recognize that, despite the fact that most hammer enamels do not need preliminary cleaning and surface preparation, it is still preferable to apply a primer first. This means that the metal surface will be under even more reliable protection. Also use the following tip: hammer enamel adheres better to the surface when sprayed at room temperature.In this case, the paint will lie flat, and the structure of the final ornament will remain uniform. Unfortunately, this is not possible with a regular brush.

For the features of hammer enamel, see the following video.

The comment was sent successfully.