Locks for metal doors: types, tips for installation and operation

Locks for metal doors are presented on the market of door structures and accessories in a huge range. Therefore, the main thing when buying them is a clear understanding of the principle of operation of each of the locking mechanisms, and the choice of the most optimal option.

Views

The classification of locks for metal doors is made according to several criteria, the determining one of which is the method of installation. According to this criterion, padlocks, surface-mounted and mortise locks are distinguished, the difference between which is not only in the installation technique and location, but also in the degree of protection, the scope of use and the level of burglary resistance of products.

Hinged

Hinged models are locking devices that are hung on the outer surface of the door leaf using special lugs welded or bolted to the door. This option is one of the weakest ways to protect premises, it is characterized by an extremely simple design and a low degree of protection. The range of mounted models is quite diverse. The models differ from each other in the type of construction, materials of manufacture, dimensions of the case and bow, as well as the mechanism of secrecy. The simplest options are classic products with arched and T-shaped arms. Their use cannot provide a high level of protection of the premises against penetration, and is rather of a preventive nature. A little more serious are semi-closed devices, in which the fixing part of the bow is protected by the device case, as well as devices of a closed design with a completely hidden bow and combination locks without keys. Hinged models are used on metal doors of garages, basements and warehouses.

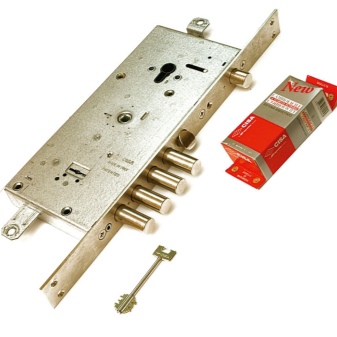

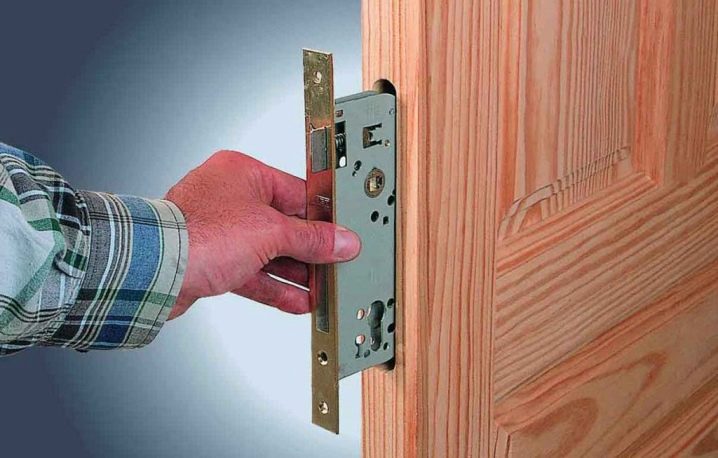

Mortise

Mortise models are the most popular type of locks and are installed inside door leaves. The advantages of these devices are a higher level of protection and a class of burglary resistance in comparison with padlocks. In addition, products are produced in the widest range and are considered the most numerous group of locking devices for iron doors. The disadvantages of mortise structures include too close arrangement of the working mechanism of products to the surface of the door leaf, which is why there is a possibility of cutting and sawing out such devices. However, these troubles can be avoided by equipping the door with additional protective plates that make it difficult, and sometimes even make it impossible to access the locking mechanism. Another disadvantage of mortise models is the complex installation, which involves the use of professional equipment and the presence of certain experience in working with metal.

Overhead

Overhead structures, unlike mortise ones, are characterized by ease of installation and can be installed independently. The devices are fixed on top of the doors from the inside and bolted in place. The advantages of locks include a sufficient distance of the working mechanism from the outer surface of the door, which makes it difficult to cut them out, as well as replacing the old product with a new one without disturbing the appearance and integrity of the door.The disadvantages include the impossibility of installation on door systems equipped with a secret rebate, as well as the ease of opening from the inside. The last moment is fraught with the unhindered leaving of the apartment of thieves who entered the dwelling through a window or through a balcony.

Functionally overhead and mortise products are divided into locking and locking and locking. The first ones do not have a latch (in common people - "dogs"), and when closing, they need to firmly press the door to the box with the help of physical effort. The second ones are equipped with a latch-tongue and a lever handle, which makes them the most convenient to use. In addition, a chain is often present on overhead models, which also increases their usability.

However, the key criterion for classifying locks is the type of locking mechanism. On this basis, devices are divided into six types.

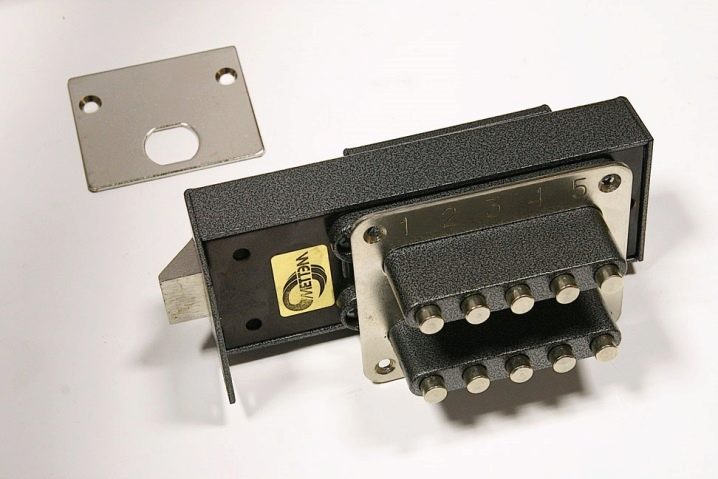

Crossbars

Crossbar locks are the simplest designs, equipped with slats with teeth and grooves, and the configuration of the grooves completely coincides with the shape of the grooves on a long key. The main difference when unlocking a bolt lock is that there is no need to turn the key in the keyhole. To open such a device, it is enough to insert the key into the well and push it all the way. In this case, the spring is compressed and the locking rail goes sideways. Crossbars are notable for their low protective qualities and therefore belong to the lowest safety class. The scope of application of transom structures involves their installation in premises that do not contain special material values. Devices can be found on metal driveways, gates, gates, and utility rooms.

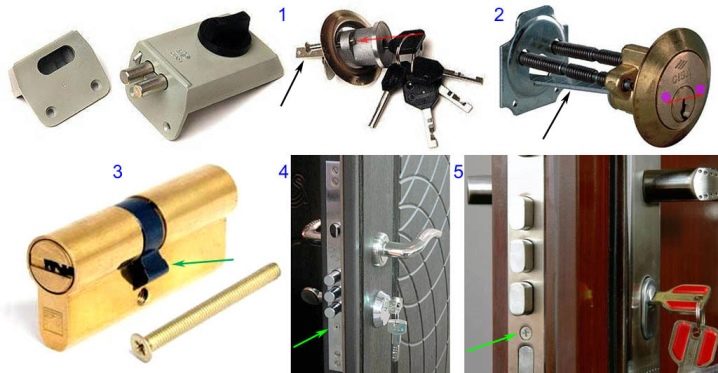

Cylinder

Products of this type are subdivided into pin and disc. The discs were invented and introduced into production by the Finnish company Abloy, which is why they got the name "Finnish". Structurally, the disc mechanism is represented by a body, placed in it by a cylinder, and free rotation disks located inside the cylinder. Each of the discs is equipped with a key slot and a special slot for the movement of the balancing rod. When installing the key in the well, the discs are rotated with the simultaneous alignment of all slots in a row. As a result, the passage for the passage of the rod is released, the cylinder with the discs turns and the lock opens. When you try to open the door with a "non-native" key, the discs are not turned and a through groove is not formed. As a result, the rod is compressed by the discs and the cylinder and the lock does not open.

Pin models are arranged in a slightly different way. The basis of their design is spring pins, which are capable of lining up in a certain order when the "native" key is placed, allowing it to turn. Such locks are called "English" and are widely used in almost all types of metal doors. The models are equipped with a secret mechanism and are recommended for installation in combination with an overhead or mortise protector - a special device that protects the cylinder.

The disadvantages of pin models include the risk of knocking out the larva, but installing a protector partially solves this problem. The advantages of cylinder devices are simple repair and easy replacement of the lock. Sometimes it is enough to change only the cylinder that transmits the torque from the movement of the key to the locking bolts. In addition, pin models are highly secure and can be used as main locking devices.

Eurocylinders are considered one of the most reliable types of cylinder structures. and provide a high level of protection of premises from unwanted intrusions. It is very difficult to open such models.Even a good specialist with a professional set of master keys will be able to do this only with a lot of noise and no less than forty minutes. Eurocylinders owe their increased strength to the materials of manufacture. The ends of the cylinders are often equipped with carbide inserts that can protect the structure from knocking out and drilling.

Some manufacturers make the first pin from refractory materials or equip products with a titanium case and protective armored inserts. Almost all cylinders are endowed with the highest degree of secrecy, which is provided by one and a half million different pin combinations. In addition, some models of eurocylinders are equipped with floating or magnetic mechanisms located in the key itself. This technology raises the level of protection to one of the highest levels, as a result of which it is basically impossible to choose a key for such a lock.

Suvaldny

This type of locks was invented a long time ago, and since then its design has not undergone major changes. Such a mechanism consists of special plates - levers, each of which is equipped with figured slots. On the keys that come with the lock, each of the slots on the leverage has its own beard, which, when the key is turned, presses on a certain plate, and that, in turn, leaves a certain distance. After each leveler takes its position, the lock is opened.

The level of secrecy of such devices depends on the number of levers and crossbars, as well as on the materials of their manufacture. For example, the six-point model has over one hundred thousand combinations. To increase the level of secrecy, lever models are equipped with lock pick traps made in the form of false grooves. It will be possible to open such a structure only by means of a duplicate made. For a high class of burglary resistance and an increased level of secrecy, lever locks are called safe locks, and, perhaps, their only drawback is their large weight and large dimensions.

Electromagnetic

Models of this type are fundamentally different from the previous versions and do not have mechanical fixation elements in their design. The lock is activated by the influence of magnetic attraction force, has high anti-burglary characteristics and high retention force to break. The only drawback of such devices is the instant opening of the locking mechanism in the event of a power outage. In this connection, each model is equipped with a power control sensor and the density of pressing the door to the box. In the event of a power outage, the sensor instantly signals a problem to the security service or the owner of the room. Usually, electronic models are installed on metal-plastic doors, as well as gates of country houses and cottages.

Electromechanical

The design of such locks has few fundamental differences from conventional mechanical models, however, the process of opening and closing doors is carried out not using a traditional key, but using a key fob, magnetic card or digital code. The operation of devices is based on electrical impulses, therefore, just like the previous type, electromechanical models are completely dependent on electricity. There are two types of such devices: solenoid and motor. The first is installed in places with heavy traffic, which is due to the fact that in the standby mode the lock is always open and can only be closed after a signal has been given.

Motor locks, on the other hand, are always closed in their normal position and open only after an electric current is applied. The devices are designed for rarely opening doors, but they are not used in door systems used for emergency evacuation of people. The same category of devices should include an invisible lock.The model has been specially designed to complement the main locking devices. The advantages of the design are the location, which is not visible either from the inside or from the outside, and a sufficiently high reliability of locking. In addition, the models have a control panel and are remotely operated.

Code

Such devices have a rather low protection class and are intended for installation in entrances and on metal gates. The locks are equipped with buttons, with the help of which the required digital code is entered. The advantage of push-button devices is that there is no need to use a key. The disadvantages include the likelihood of frequent erasure and sinking of buttons, as well as refusal to work at extremely low temperatures. Roller models also belong to combination locks, in which, to enter a digital code, you need to turn the roller with numbers to a certain mark. However, such devices are even weaker and more fragile than push-button devices and are rarely used.

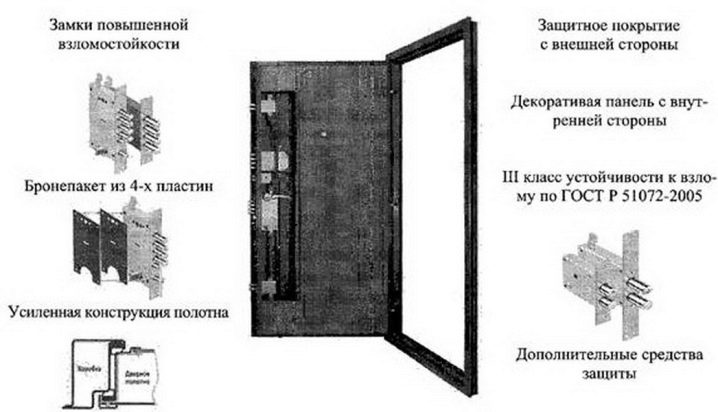

Burglary resistance classes

There are 4 classes of burglary resistance. The first class includes models with the simplest device and a reduced level of complexity. If you have the necessary tools, you can open such a lock in a few minutes. Class 2 also includes not very reliable models, which can be opened in 5-7 minutes. The third class is represented by the most numerous category and includes locks installed in apartments and private houses.

The products are highly durable and can resist burglary for 15 minutes. The fourth class includes serious devices that are installed on armored doors in rooms with special protection requirements. It is, of course, possible to hack such a mechanism, but not less than in half an hour and only if you have a professional tool and a lot of experience. All four levels of class are clearly spelled out and regulated by GOST 5089-2003.

Along with burglary resistance, an equally important characteristic of locks is the level of secrecy. So, models with low secrecy do not have additional protection, and the number of pin combinations ranges from 10 to 10,000 units. Mid-range models suggest the presence of 5 thousand to 5 million combinations and are often protected from pick keys. Top-level locks are the most reliable. They are completely protected from mechanical hacking and have up to a billion different pin combinations. Opening the door with such a lock will only work if you cut and remove the locking device or remove the canvas from the hinges

Manufacturers

The leader in the rating of locks for metal doors is the Italian company Atra-Dierre. The manufacturer is responsible for each lock and provides the consumer with quality products. Models of another Italian company, Mottura, are also time-tested and are widely demanded in the domestic market. The products are equipped with several degrees of protection, a replaceable security element and an anti-knockout lock.

The third place is deservedly occupied by Cisa from Italy, the fourth is occupied by the Finnish Abloy, and the fifth is the German concern Abus with its famous EP-10 model. The Russian company "Guardian", which produces reliable and inexpensive products, closes the top six. The company's models belong to the fourth class of burglary resistance and practically do not leave a chance for opening.

How to choose?

The choice of a lock depends entirely on its purpose and the security requirements of the facility. When buying a model for a steel apartment door, you need to take into account that even the most modern and reliable lock does not give one hundred percent guarantee of the inviolability of the home. In this case, it is better to purchase two or three locks, different in the method of installation and in the type of locking mechanism. This will significantly complicate the work of intruders and reduce the likelihood of their penetration into the premises.If the door design does not imply the installation of two or three locks, you can limit yourself to buying a combined model.

Such versatile products are available from any well-known manufacturer, including Guardian, Mottura, Vachette, Elbor and Barrier, so it will not be difficult to purchase them. Structurally, combined locks are a combination of lever and cylinder mechanisms, made as a single block, which allows you to acquire, in fact, two locks in one case. Also, when choosing a model, it is necessary to familiarize yourself with the accompanying documentation and check for the presence of a security certificate - a document that prescribes the burglary resistance class and the level of secrecy of the lock, as well as the maximum number of opening-closing cycles.

Installation methods

The insertion of the lock into the metal door can be done by yourself. Installation of the overhead model looks like this:

- markings should be applied at a height of 80 to 100 cm;

- with a drill of the appropriate size, you need to drill a hole to create a well;

- fixing the lock body on the door leaf is done by bolting or welding;

- the key hole on the outside of the door must be covered with a decorative strip;

- mounting of the strike plate is carried out only after careful measurements and firm confidence that the lock will close without jamming and extraneous knocking.

Installing a mortise lock requires some labor and more installation time. The first stage of work will be marking the end of the door leaf. Moreover, it is required to put risks with a small margin necessary for the free entry of the castle into the recess. Usually 1-2 mm is sufficient. Next, using a grinder on the end of the canvas, you need to make a slot of the desired size. If there is no grinder, you can use the drilling method, and clean up inaccuracies and protrusions with a file. Then, on the door leaf, it is required to make a hole for the cylinder, mark the fastening points of the lock and cut a thread in them.

After the preparatory work is completed, the lock and cylinder should be put in place and securely fixed. Then you need to drill holes for the crossbars, grease their ends with toothpaste, close the door tightly and try to close the lock. As a result, clear marks will remain on the door frame striker, indicating the location of the holes. The final step will be to drill these holes and check the operation of the lock.

Operating tips

In order for the lock on the iron door to serve as long as possible, a number of simple rules must be followed. One of the main conditions for the smooth operation of the locking device is the absence of sharp blows by the door, which lead to jamming of the mechanism, and after a while - to complete failure. Therefore, in places with high traffic traffic, it is recommended to equip the doors with a door closer. This will allow the canvas to close smoothly and softly and exclude its powerful impacts on the box.

Another condition for the correct operation of the locking mechanisms is the prohibition on littering the keyhole with foreign objects. It is strictly forbidden to push coins, matches and pins into the hole, as well as allow dust, sand and precipitation to enter the lock. In addition, it is necessary to regularly lubricate the working mechanism with a special compound for locks, and if it is not available, with machine oil. Also, when opening and closing the doors, you need to carefully ensure that the key goes into the well until it stops, and only then start turning it. Otherwise, the key beards may not reach the right place, break off, get into the locking mechanism of the lock and spoil it.

A well-chosen lock for a metal door significantly reduces the likelihood of opening and breaking, provides reliable protection of the premises and allows the owners not to worry about the safety of their property.

For information on how to choose a lock for a door, see the next video.

The comment was sent successfully.