Thermal break doors

When purchasing an entrance door, we expect reliability, functionality and durability from it, therefore, the type of room for which it is intended should be taken into account. For example, an ordinary metal door, which is perfect for an apartment, due to its high thermal conductivity, will cause trouble for the owners of private houses in the form of condensation and heat loss. The thermal break technology helps to eliminate this.

What it is?

Thermal break is the separation of a material that conducts heat into two or more parts using an insulating material or a layer of dry air, clogged in the cavity of the structure. Using this method makes it possible to impair heat transfer between the house and the street, thereby reducing energy costs and heat losses. The simplest example is a traditional Russian canopy - an unheated room that prevents a sharp collision of cold and warm air, equalizing the temperature. A more modern variation is a double door, suitable for those who cannot allocate a room for a vestibule.

However, such disadvantages of paired structures as cumbersomeness, inconvenience of use (it is necessary to open two leaves), loss of usable space, door sagging and leakage have over time prompted engineers to create doors with a thermal break.

Design features

The developers managed to achieve impressive insulating qualities due to the observance of the well-known physical rule: the delineation of warm and cold surfaces reduces heat transfer.

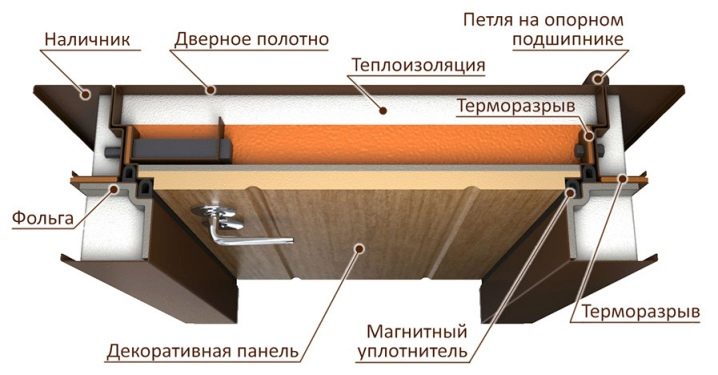

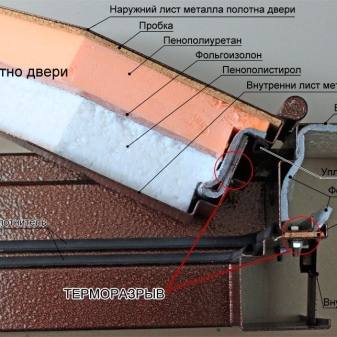

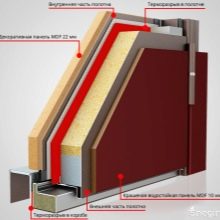

In the device of the thermal door, several key points can be distinguished:

- two sections of the door framethe cavity of which is filled with an insulating material (mineral wool, foam);

- between sections - a layer of material with low thermal conductivity (cork, polyurethane, polyamide);

- multilayer door leaf... The space between the outer and inner panels is filled with two or more types of insulation, which are insulated with a plastic or wood insert.

The combination of these solutions makes it possible to exclude from the design of the street door the so-called "cold bridges", through which heat leakage occurs.

Materials (edit)

The quality of the thermal door directly depends on the materials used by the manufacturer to create it. Practice has shown that the construction of a metal door is more effective in terms of thermal insulation and security than products made of polyvinyl chloride (PVC) or wood. But even in this case, there is a risk of encountering low-quality products made of thin steel. They bribe with their cheapness and low weight, but the strength of such doors is no more than that of a can. Therefore, it should be remembered that the reliability of the structure is directly proportional to the thickness of the walls of the metal frame. The standard outer sheet thickness is 1.8 mm, but safety experts recommend a minimum thickness of 3 mm.

The inside of the door with a thermal break is filled with various insulating materials. Among the most common:

- Pvc - has established itself in production as the most cost-effective material with high insulating properties. Its multi-chamber structure, due to air gaps, retains cooled air, preventing heat leakage. The main disadvantage of this filler is its low frost resistance. Therefore, it is only suitable for regions with an average winter temperature of at least 15C.

Mineral wool - a material whose characteristics are ideal for creating thermal doors. Among the main ones:

- Air exchange - eliminates the formation of condensate;

- The high combustion temperature guarantees fire resistance;

- Soundproofing;

- Resistant to atmospheric conditions, including low temperatures;

- Economical.

- Styrofoam - an inexpensive type of insulator. The design based on it is absolutely impervious to both warm and cold air currents. In addition, such a door can withstand temperatures below -100C.

- Polyurethane foam - a high-strength plastic material with a porous structure that retains heat well and serves as a barrier to sounds and noise. Such filling gives additional rigidity to the door leaf, increasing its service life.

- Fiberglass is also a good sealant, but it has one significant drawback: it is believed that when heated, it becomes toxic to humans. Therefore, doors with such a filler are often installed in industrial premises with provided ventilation.

Despite the obvious advantages of the listed types of insulating materials, the priority, according to experts and consumers, belongs to wood. The density of the solid wood mass ensures high tightness, and its environmental safety makes it preferable to use such doors in residential buildings. The only negative is the high cost.

Advantages and disadvantages

Among the advantages of using thermal doors are:

- Preservation of heat in the room, which, of course, reduces the cost of heating the house;

- Resistant to atmospheric influences. Thermal break minimizes the difference in temperature affecting the product. Such doors are not covered with moisture inside and, accordingly, ice, which prolongs their service life and retains their aesthetic appearance.

- Suitable for harsh climatic conditions;

- The need for insulation, as well as the arrangement of an additional thermoregulation system, disappears;

- High noise and sound insulation;

- High pressure resistance and tightness.

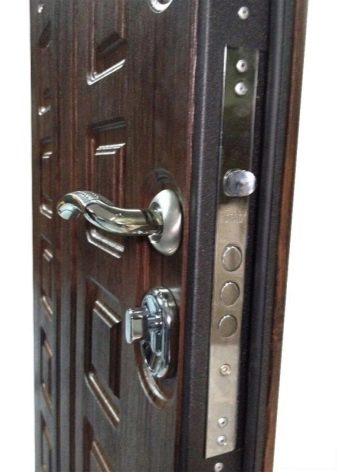

So that your purchase does not lose the mentioned advantages, turning them into disadvantages, you need to pay attention to several conditions. When choosing a door, you need to carefully check the door leaf. Its surface should be absolutely flat, without dents and holes, without bevels, slopes and other deformations. The heavy construction of the product is undoubtedly a plus for safety and reliability, but it can shorten the service life if you use conventional fixing elements. Therefore, it is necessary to complete with strong hinges, or better with special levers, which stably fix the canvas.

Special requirements apply to the installation of doors with a thermal break. Any undetected damage, bevels, slopes, any error during installation can negate all the thermal insulation benefits. It is possible that you will need to additionally buy handles that also have a thermal break function, since ordinary fittings can contribute to heat loss.

If you plan to use the thermal door in a room with high humidity, you must additionally install a supply and exhaust ventilation system. Otherwise, none of the magical properties of the door will help to avoid the risk of condensation.

Views

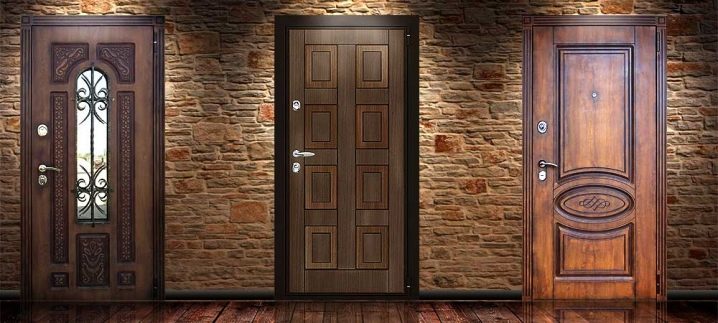

The growing number of manufacturers on the street door market provides a variety of design modifications, their characteristics and combinations of constituent components. Classification according to the criterion "price-quality" distinguishes models of economy, business and elite class.

For the production of budget options, a thin metal profile and trim from inexpensive materials are most often used: leatherette, MDF, lining. The final product is quite warm and light, but not reliable due to its small thickness.

More expensive specimens have a laminate as an external finish that imitates wood. The insulated door looks decent, is inexpensive and is scratch and abrasion resistant.

Elite models, as a rule, are made to order and trimmed with natural materials. Most often they use high quality MDF or glued natural veneer. A solid massif of oak and other species is much more expensive than analogues, but it adds chic to the products, emphasizing the social status of the owners. The double door is especially luxurious with this finish.

Those who do not plan serious expenses, but pretend to be solid, will like the metal filament in the decoration. This is the processing of metal in a special way (punching or manual cutting) to give it a three-dimensional pattern.

Dimensions (edit)

Knowing the main characteristics inherent in models with thermal insulation will greatly simplify the choice of the consumer. Key points to look out for:

- Steel sheet thickness. As mentioned above, models with a thickness of 1.5-1.8 to 3 mm have an advantage;

- Door leaf thickness starts from 70 mm and above. It all depends on the "filling" of the door and on the number of layers of noise and heat insulator;

- Typical product dimensions most manufacturers vary in wide ranges: from 0.86 to 1 m in width and 2-2.5 m in height.

You can also choose two-leaf and one-and-a-half models. A variety of choices makes it possible to purchase doors for almost any openings or make to order;

The average weight of a metal door is about 100 kg. Heavier structures, as a rule, are made according to individual orders. A significant influence on weight is influenced by the thickness of the steel, the presence of decorative coatings, fittings and other details.

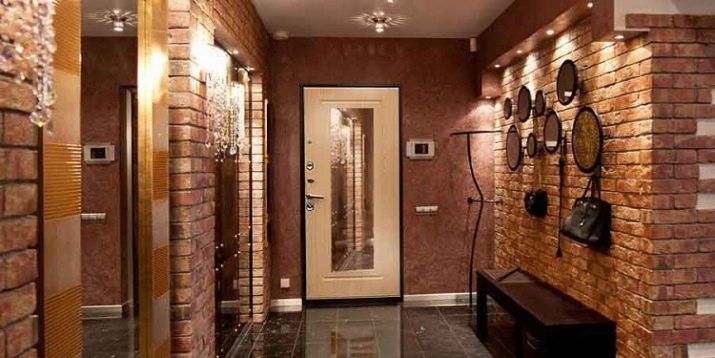

Colors and designs

The front door is the hallmark of the dwelling, which we choose for years. Therefore, it is important to pay attention not only to its functional features, but also to its appearance. Modern technologies give manufacturers almost unlimited possibilities for street door design and choice of colors. Let's consider several popular options.

If the house lacks airiness and lightness, a white Provence-style entrance door will achieve the desired effect. The color of golden oak will add warmth and conviviality. The color of bleached oak is also relevant, which allows you to fully enjoy the beauty of the wood pattern. Will never lose popularity of dark wenge color models... This design looks expensive and elegant, especially when combined with carvings and filigree patterns.

Giving the entrance doors the effect of antiquity, or in other words, patina, is another fashionable design trend. This process is completely manual and consists of several stages: priming, sanding, patina application and varnishing. Manipulations with it allow you to achieve the effect of cracked paint, leather, corduroy and many others. Artificially aged surfaces look harmoniously with forging and give the input product individuality.

An entrance door with a mirror on the inside is a good design move for small hallways. In addition to the fact that such a solution saves space, the mirror surface also visually enlarges the space.

Glass doors are more suitable for the private sector. They look stylish and beautiful and are an additional source of light. Despite the seeming unreliability, in practice, tempered and heat-resistant glass is used for production, which is rather difficult to damage. In addition, for additional protection, such doors are manufactured together with forging. Decorative forged elements will add sophistication and elegance to the exterior of any home. If you wish, you can order stained glass inserts instead of ordinary glass.

Powder door finishing is a widespread technology. Painting is carried out by spraying the powder in an electrostatic field, after which the polymerization of the powder paint occurs at a temperature of 140 to 200 degrees.

A wide variety of colors, as well as additional effects (silk, crocodile skin, antique, etc.) - this is an unpaved field for designers.

The practical function of this type of finish is the protective properties of the coating against mechanical damage and an unfriendly environment.

Manufacturers

There is a wide range of models and finishes available from manufacturers of doors with thermal breaks. One of them is Torex company... The plant was founded in Saratov and has been operating since 1989. According to customer reviews, one can judge the high quality of products, service at a decent level and customer care. The “Bullfinch” models have the greatest preference. They were released in several series for different climatic zones:

- "Snegir 20" - 3 layers of sealant, cloth - 76 mm, created for regions with warm and humid winters with temperatures not lower than -18 C, withstands short-term temperature drops up to -20 / -25 C;

- "Snegir 45" - 3 layers of heat-insulating materials, cloth - 95 mm, designed for areas with an average temperature of -25C, but retains its properties up to -40 - -45C;

- "Snegir 60" - 5 layers of insulation and 118 mm of canvas, it is successfully operated in conditions of extremely low temperatures (from -45C).

Another popular manufacturer is the Termo factory, offers a wide variety of thermal doors for every taste and budget. The economical options include the Termolight model. It has three layers of box insulation and four layers of canvases, width - 85 mm. This model is the base model in the "Termo" collection and is equipped with the obligatory minimum of safety and heat preservation options. The cost of such a door is about 30 thousand rubles. The next in the line are the models "Termo", "Termodeca", "Termo +", "Termodeca +", which differ in five thermal layers, web thickness from 98 to 100 mm, and three sealing bays. And finally, super warm products - "Termopan" and "Termowood" with seven layers of thermal insulation. By the way, the company delivers to all regions of Russia and the CIS.

You can also find thermal samples at Lex... Although their assortment is not so diverse, the quality declared in the description allows them to be mentioned in this review.

Novosibirsk PO "Pillar" pleases not only with the assortment, but also with an attentive attitude to design. For example, the Luigi Termo model, decorated with an insert of glass and forged elements, is an excellent choice for a cottage.

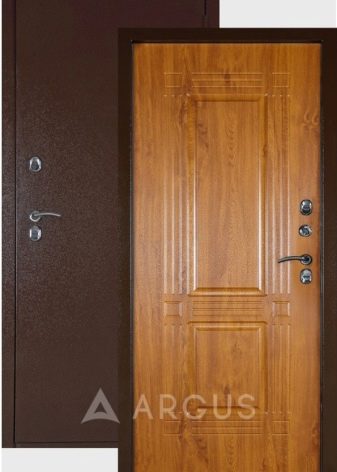

In the catalog known in the market company "Argus" not so long ago frost-resistant doors of the "Argus-Teplo" series appeared.

This is not a complete list, which nevertheless gives reason to conclude that the buyer is not limited in the choice of doors with a thermal break.

How to choose?

When choosing an anti-freeze door for a country house, pay attention to the following points:

- take into account the climate of the region residence, since the models differ in terms of frost resistance;

- pay attention to the thickness outer steel sheet. The optimal parameters are 1.2-2mm;

- inspect surfaces for bumps, scratches and other deformations, which will save you from unpleasant surprises in the future. This also applies to the shape of the canvas. The presence of bevels or slopes affects the degree of sealing;

- take a closer look at samples with an additional rubber seal... This significantly increases the thermal insulation functions of the structure;

- to avoid freezing, discard the eyes and vertical closure. This also applies to conventional door handles without thermal break;

- find out what type of insulation stands in the model you like, since some types (for example, fiberglass) are toxic to humans, and it is not recommended to use them in residential premises;

- pay attention to the components... Ordinary hinges for a massive (weight can reach 120 kg) thermal door are categorically not suitable. An acceptable option may be special levers that securely fix the canvas.

- in pursuit of quality, do not overlook the exterior finish... Here, the choice is more than rich in the works of designers. However, it must be remembered that street doors in private houses are in direct contact with the environment, therefore, it is advisable to choose a metal finish for the outer panel.

Having found the perfect door, it is very important to install it as correctly as possible. Any displacement will nullify the functionality of the structure.

To avoid disappointment, when installing, carefully read the attached instructions, or rather contact the specialists, especially since many companies have regular installers.

From this video you will find out what is inside the door with a thermal break.

The comment was sent successfully.