Fire doors

During the construction of any buildings and structures, special attention is paid to fire safety. As a fulfillment of special norms during the delivery of objects, a number of measures are usually assumed: competent design, installation of fire-prevention systems and equipment, including doors.

What it is?

First, you need to understand what fire doors are, what are their differences from conventional entrance structures. In the technical literature, they have several names: fireproof, fireproof, fireproof, fireproof. Officially, such structures include products that are installed as a barrier to prevent the spread of fire in a fire.

The main features characterizing fire safety:

- High degree of fire resistance... The door should create an obstacle to the spread of fire, as this will give an opportunity to gain time necessary for the evacuation of the victims.

- Immunity to high temperature... The material from which fireproof structures are made must be resistant to temperature deformations.

- Non-toxic raw materials, because in the event of a fire, the doors must not become a source of harmful combustion products.

- Easy access for rescuers to the fire site, which is ensured by the functionality of the closing systems.

Design of fireproof products

In terms of basic elements, fire doors differ little from ordinary ones. Typically, a door block includes a leaf, a frame, a fastening mechanism and a lock. The canvas is usually made on the basis of metal stiffeners, which are subsequently sheathed with sheets of steel, glass, wood. In wooden models, the frame can be made of timber.

The main difference is specialized components and fire-resistant materials. These include the following.

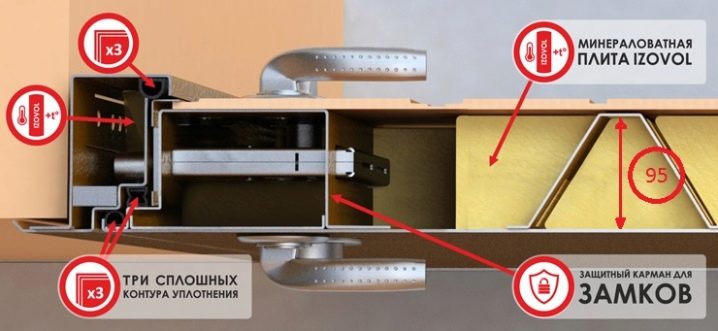

- Seals... Since any doors assume in their design slots at the junction of the sash with the frame, the fire-fighting models provide for the laying of various types of cushioning materials along the entire contour. It is convenient to use a self-adhesive seal. With its help, any solid door can be turned into a fireproof door. Protective anti-smoke seals contain mineral wool, which does not allow burning to get inside the room.

There are options with a thermosetting tape overlay, which, under the influence of temperature, foams and completely seals the door, protecting it from toxic combustion products.

- Insulating insulation... It filled the space between the canvases, since fire doors always consist of several layers. An insulator protects the web from heat. The most common option is mineral wool. Basalt fiber slabs withstand high temperatures for a long time, and the longer the fiber, the better. Experts identify silicon as a material with excellent insulating properties. It is resistant to drops of up to 1200 degrees and above. For glass doors, thermal film or a special gel is used to fill the space between the layers.

- Coating... Fire doors can be decorated with different types of materials. The leader is high temperature resistant powder coating. Cladding with fire retardant laminate or veneer, wood or MDF panels impregnated with protective agents is also popular.

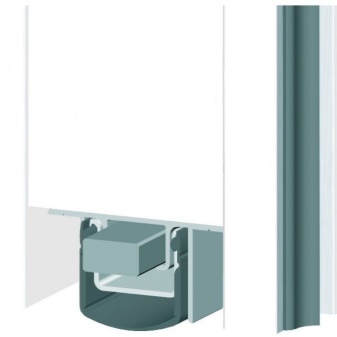

- Thresholds... The device is primarily needed to provide protection against smoke and gas. In addition, it is traditionally a barrier against noise, dust, drafts, and heat loss. Thresholdless designs of smoke and gas tight doors usually contain a hinged threshold to seal the circuit. In the case of thin glass models, the automatic delivery option is used.

- Door closers... Experts advise installing a self-closing device on fireproof doors, since only in the closed position the structure fulfills its protective function. They are floor-standing, outdoor and built-in. Professionals pay attention that in the presence of double doors, it is necessary to install a leaf synchronizer. Modern technologies make it possible to automate the rules of the closing mode, which will eliminate the human factor of suddenness in the event of a fire.

- Ventilation... Some specialized premises, according to regulations, must be equipped with a fire door with a ventilation valve. These include switchboard and server rooms. In this case, not only the box, but also the lamellas on the grate is equipped with a sealing loop made of thermosetting material.

- Locking devices... Locks, handles and other fittings on fire-resistant models must remain functional under the influence of high temperatures, not jam or deform. In addition, they are required to provide quick access, that is, it is easy to open when necessary. Recently, the anti-panic system has proven itself well, allowing to reduce the time of evacuation in smoke conditions.

See the following video for the principle of operation of the Anti-Panic system.

What types are there?

Doors are classified according to their design features.

By the number of leaves

- Single-leaf or single-leaf design.

- Two-field system. Double-leaf doors can be of equal size, with leaves of the same width, and different-sided - with different leaves. In addition, a distinction is made between active and passive door parts.

Opening direction

- Rights.

- Left.

The side is determined by the position of the outer door hinges of the active leaf.

By opening mechanism

Fire doors must provide a good seal. They mainly use swing options. In this case, the door leaf is attached to the frame with hinges. The disadvantage is the free space that is needed near the sash when opening.

In public spaces and offices, pendulum models are popular, when the sash opens in any direction.

A sliding structure is often found, for example, in public catering factories. These doors do not require much space. Since this model implies a gap between the canvas and the wall, fireproof structures are equipped with seals along the box.

At the place of use

The site classification is extensive and depends on where the door structure is installed. The most common options can be identified:

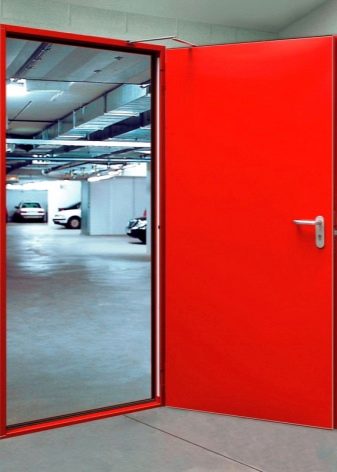

- Driveways.

- Apartment.

- Interroom.

- Tambour.

- Hangar.

- Warehouse.

Corridor and vestibule structures are sometimes produced with a transom to provide ventilation. Insulated driveways and apartment options are popular among the population of apartment buildings.

By type of canvas

There are 2 main types of fire doors.

- Deaf, the designation in the technical documentation corresponds to the stamp "G". For example, the code "Г2П" means a blind double-sided right sash.

- Glazed or translucent ones have the "C" code.

By the degree of safety

Depending on the various design features that characterize the protection against a particular factor, the doors are divided into several groups.

- Explosion-proof with ventilation grill... Regulatory documents prescribe the installation of door structures for server rooms and electrical control rooms, assuming the presence of a ventilation hole that occupies at least 25% of the door leaf area. The grille is made of polyurethane lamellas. In addition, the plates have spacers made of a material that has the property of thermal expansion. As a rule, sodium silicone is present in the composition. When ignited, the lamellas increase from temperature rise, the gasket turns into foam, which closes the ventilation slots and prevents the flow of hot air.

For protection against mechanical influences, such as explosions, steel blinds are used. The designs may vary depending on the basic configuration.

- Smoke and gas tight... The main design feature of the models is a special contour seal along the perimeter of the entire canvas to ensure the impermeability of carbon monoxide and smoke. In addition, any smoke and gas tight door is produced with a drop-down threshold that seals the circuit. The function is configured automatically and is as follows. When the door is opened, the threshold rises, when it is closed, it is lowered. Fire protection sheets are available in wood, glass and metal.

- Armored Fire Explosion Resistant... Products are characterized not only by the degree of susceptibility to fire, but also by the class of bullet resistance, which must be confirmed by certificates. A distinctive feature of armored doors is to open only with the leaf outward. The door with the use of armor is the most burglary. Such structures are installed in premises intended for storing valuables: banks, cash desks, safes, historical archives; as well as in departmental institutions: scientific laboratories, test sites, security posts.

- Sliding fire retardant... Sliding doors are provided with a seal in the form of a refractory film. When ignited, with increasing temperature, it increases in volume and closes the cracks. Sliding fire-retardant models are heavy, therefore, most often they are equipped with electromechanical drives that fix the canvas in a closed position. In this case, an autonomous battery system is additionally provided to eliminate the possibility of malfunction in the absence of electricity.

- With anti-panic... Fire doors are usually equipped with a fire-resistant lock. In crowded places, structures are equipped with an electromechanical access control system with a drop-down threshold, in apartments it is advised to install "anti-panic". In this case, the lock is opened from the inside by light pressure, perhaps even with an elbow.

Types and classification

Fireproof doors can be classified according to several qualities. According to the Technical Regulations on fire safety requirements, one of the criteria is the fire resistance limit. This characteristic shows how long the door can hold out under the influence of fire. The fire resistance limit has its own code in the designation. For all door structures, it begins with the letters EI, then the figure corresponding to the fire resistance time in minutes is indicated.

Types of locking systems

- The length of time during which the structure is able to withstand is 90 minutes... Code EI90 According to their design features, one-leaf and two-leaf doors can be distinguished. To determine which option is advisable to install in a particular room, it is necessary to measure the width of the opening. In cases up to 110 centimeters, single-leaf models can be used.If the width is greater, then the width of the double sashes can be made both the same and different. More often, structures of the first type are installed in rooms with a high level of danger.

- Minimum fire resistance 60 minutes... Doors of the second type of degree EI60 are considered a universal class of models intended for installation in buildings with various functional loads: private houses, offices, civil buildings. Doors of this type can be divided by the type of door leaf into blind and with inserts, by the number of leaves - single and double. When choosing, you need to be guided by the width of the opening and the need to increase the view of the door space.

- The third type includes models that can hold a flame for 30 minutes.... EI30 code. The lowest degree of protection allows these doors to be installed in small areas.

Specifications

All technical properties of fire-fighting products are classified according to the degree of fire resistance and are written in Latin letters.

- E - characterizes the loss of integrity. It is understood that after the limiting value of time, cracks and deep holes will begin to appear, however, losses in the bearing properties of the structure have not yet been obtained.

- I - qualifies the loss of thermal insulation, that is, it shows how long the doors will be able to withstand under the influence of hot air. For example, models of the I15 class can be opened with bare hands when heated for 15 minutes without the risk of getting burned.

- W - determines the time during which the heat flux is maintained.

- S - shows the ability of the door to contain carbon monoxide.

- R - regulates the loss of bearing capacity. The indicator characterizes the period of time after which the door leaf itself and the frame will begin to collapse.

Dimensions (edit)

Requirements for the installation sites of fire doors are established based on SNiP and GOST.

Standard openings must have the following parameters.

- Height is not less than 180 cm.

- Width from 80 to 120 cm.

The thickness of the steel sheets that are included in the structure affects the reliability and integrity of the product, the degree of fire resistance depends on the type and thickness of the insulating material. A metal specialized door structure, as a rule, weighs at least 120 kg.

Finish and texture

The latest technologies allow manufacturers to obtain a wide range of fire-rated doors in various designs.

- Metal models covered with a special thermal spray.

- Popular door leaf cladding with solid wood, since in this case two functions are performed: protective and aesthetic. The wood texture looks noble and natural.

- Flame retardant laminate or veneer decor has a lower cost... With its help, you can get a different texture of the canvas without losing its protective properties. MDF panels and artificial leather impregnated with protective agents are also used by designers.

- Translucent doors are light and airy on their own... The material of the stiffeners, their color and texture are interesting here. They can be aluminum, steel, wood.

Flame retardant materials

Building codes (SNiP) regulate raw materials that can be used for the production of fire-fighting products. In addition, they are classified according to the degree of toxicity, combustibility, flammability, spread of fire and smoke-generating ability.

Wood, metal, glass, plastic are used as materials for fire-resistant door structures. However, you need to understand that only the door leaf is made from the specified raw materials.

- Wood... Wood treated with special protective agents can be used for the production of doors of the third type of fire resistance. This also includes veneered products and canvases with panels made of MDF. The box in such cases can be either wooden or metal.In the design, a specially foamed seal is necessarily used to seal the space between the inner and outer door leaves.

- Steel and iron... Metal alloys are the most popular material for the production of fire protection products. The door leaf is made of steel sheet with a thickness of 1 millimeter. Mineral wool is often used as a filler. Iron doors are characterized by a high degree of fire resistance.

- Glass... According to SNiP, such doors are called "translucent" and are divided into 2 categories. If the glazing area is more than 25%, then they are classified as glass, less than 25% - glazed. The degree of fire resistance in this case depends on the thickness of the web. The box and frame are usually made of aluminum. Partitions are usually made of steel or aluminum profiles. The door leaf is made of fire-resistant glass with a gel-like non-combustible filler between the glass layers. Raw materials are popular for the manufacture of door structures and windows in public spaces, offices, since, in addition to safety, they perform an aesthetic function.

- Plastic... PVC products do not withstand prolonged exposure to high temperatures, so plastic fire-fighting products are nothing more than a myth. In addition, plastic is toxic when burned.

Where are fire resistant models installed?

The use of fireproof models is usually planned in the design of buildings in accordance with the requirements of regulatory documents.

Primary room types

There are several unconditional types of premises in which fire doors are required.

- First of all, the installation of fire-resistant entrance structures is carried out in places subject to spontaneous combustion. These include, for example, fuel and lubricants warehouses and hangars, garages, repair shops, bakeries, depots, boiler rooms, switchboards. To ensure effective protection of industrial hangars, fire-prevention swing gates are used. They are large in size, but have all the properties required for safety.

- Public buildings. In cinemas, educational institutions, hospitals, shopping and entertainment centers, security measures are checked regularly. The installation of such door structures is envisaged in the project.

- Premises for storing securities and things. Banks, museums, archives cherish values very scrupulously and anxiously, since they often have historical significance.

Indoor installation locations

Fireproof doors are installed in apartment buildings. The following openings are equipped with them.

- Driveways.

- Apartment.

- Attic and basement entrances.

- Elevators and niches for communications, cable tunnels.

- Exits to public floor areas.

If an office or a store is located on the first floor of a residential building, then the opening between them must also be equipped with a fire door. Indoor accommodation options are governed by the relevant rules and regulations. Individual doors with fire protection can be installed in the following locations.

- Corridors of offices, warehouses, workshops.

- Ladders.

- Interior doors are installed both in the apartment and in office premises.

- They are used to equip loggias and balconies.

How to choose the best ones?

When buying a fireproof door, buyers usually focus on the price, depending on the degree of fire resistance. but experts advise taking into account such factors as the presence of a fire alarm system and the distance from the fire brigade areas.

- An important criterion is the type of walls, since this determines the definition of the design of the door frame. If the degree of fire resistance of the wall panels is low, then it makes no sense to purchase a high-strength door.

- Aesthetic component Is usually the most pleasant and easily achievable criterion.A wide assortment, modern technologies make it possible to make a door leaf not only safe, but also a beautiful piece of furniture.

- It should not be forgotten that the fittings fireproof door structures must also have fire-resistant properties. Manufacturers offer a wide range of refractory materials.

- Since one of the requirements is easy access rescuers to the place of fire, when choosing, you should pay attention to the door hinges. It is better if they are equipped with bearings, which will provide a smooth ride and prevent the door mechanism from jamming in the event of a fire.

- Locks on fire doors better equipped with an anti-panic function. In the event of a fire, it can be used to quickly exit by opening the door from the inside by pressing the handle without much effort. This is especially important for families with children, the elderly and the disabled.

Like any product requiring testing, a fireproof door must be certified.

Large manufacturers, which have established themselves in the market, present all available documents in the proper form when purchasing. Usually, such a package necessarily includes a certificate and a guarantee. The quality always depends on the materials used, since the production technology is simple. In this regard, experts advise not to overpay for brands and logistics services for the delivery of foreign analogues, but to take a closer look at domestic options. Each region has its own firms, however there are several companies that are known throughout the Russian Federation.

- Serpukhov Electromechanical Plant has been known for over 70 years, it uses modern advanced technologies.

- Phototech and ORMAN specialize in the production of translucent refractory products.

- Modul-K produces a wide range of fire-fighting products from budget to luxury with an aesthetically pleasing appearance.

The comment was sent successfully.