How to insulate an entrance metal door?

With the advent of cold weather, owners with reliable metal entrance doors have a global problem. The appearance of the door deteriorates - drops of water appear on it, frost, ice on the inner surface. The atmosphere of the living space is changing. If you insulate the front door, then all this can be avoided. You can solve this problem on your own without involving specialists.

Materials and tools

Modern materials allow any home to be protected from the cold.

For the insulation of metal structures, the following are used:

- Styrofoam;

- polystyrene;

- mineral wool;

- polyurethane foam;

- foil-clad isolon, penofol;

- sealant.

In addition to heaters, you will also need hand-held locksmith tools:

- tape measure, pencil;

- screwdriver, screwdriver;

- drill with drills for metal;

- scissors or a sharp knife;

- awl, hacksaw, jigsaw;

- sandpaper, scotch tape;

- glue (liquid nails), screws - self-tapping screws;

- acetone or alcohol.

Decorative materials:

- MDF - decorative panels or plates;

- decorative film with a pattern that repeats the texture of wood;

- paints and varnishes;

- leatherette that imitates the skin.

Safety precautions must not be neglected.

When performing locksmith work, it is important to have:

- polymer coated gloves;

- goggles to protect the eyes from mechanical particles, debris;

- respirator for respiratory protection.

Which insulation is better?

The preservation of heat in your home depends on high-quality heat-insulating material. When choosing it, it is important to take into account the design of metal doors and their location.

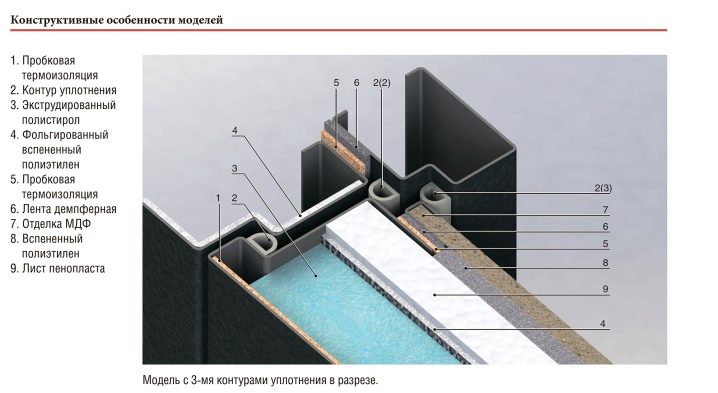

Styrofoam obtained by foaming (filling with gas) polymers. One of the cheapest materials. It has excellent thermal insulation properties, is not afraid of dampness and retains its shape. Styrofoam will keep warm well on the door in the apartment. In a private house, it will not be reliable enough, but if it is supplemented with polyurethane foam and foil isolon, it will last for many years. In case of fire, it emits chemical compounds harmful to human health.

For good sound insulation, a slab three centimeters thick is enough.

Expanded polystyrene - material obtained from polystyrene and other styrene copolymers. More expensive than Styrofoam. Moisture-resistant insulation with heat-insulating and sound-insulating properties. Denser than foam, wear-resistant, safe for health. There are refractory modifications.

Polystyrene - material obtained by polymerization of styrene. It has dielectric properties, is rigid, has high thermal insulation properties, and is moisture resistant.

The materials listed above are ideal as insulation for the front door of a private house, country house. They provide excellent protection against moisture and frost.

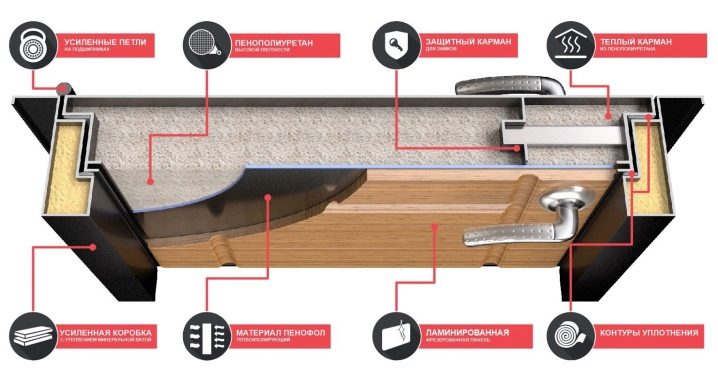

Mineral wool - inorganic fibrous material. Effective as a heater. Same price point as Styrofoam. Depending on the fiber, it is divided into groups: glass wool, slag and stone (basalt). Made from natural non-combustible materials, it is environmentally friendly. Sold in rolls or slabs. If it is used to insulate a door in a private house, a water-repellent material is needed.

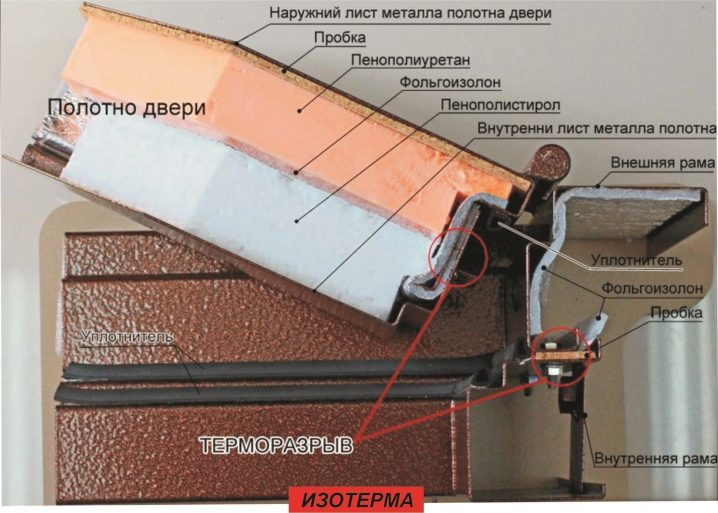

Polyurethane foam - material that belongs to gas-filled polymers. This group includes: foam rubber, ready-made thermal insulation panels, polyurethane foam. Foam rubber has good thermal and sound insulation properties. When burning, it is highly toxic, it belongs to highly flammable substances.The exception is special-purpose foam rubber CMHR. It is distinguished by its special elasticity and fire safety.

Foil isolon, penofol - eco-friendly material. In the process of its manufacture, foil and foamed polyethylene are used. It is a modern, popular, economical, wear-resistant, moisture-resistant insulation. Possesses excellent soundproofing properties.

Do-it-yourself thermal insulation of the door frame

For high-quality insulation of the front door, it is important to carry out the necessary work on the insulation of the box. It happens that workers, in a hurry to install the door, leave noticeable gaps between the frame and the sides of the doorway. When you start insulating your door, you need to fill all the cracks with polyurethane foam. After it hardens, all protruding parts must be cleaned. Plaster the joints and put them in order.

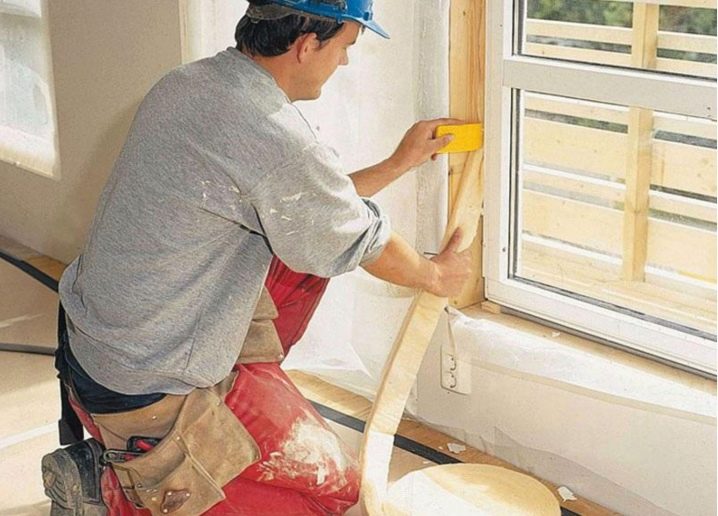

After that, it is necessary to eliminate possible gaps between the metal door and the frame. To do this, we purchase a silicone tape seal (you can use foam rubber). We treat the perimeter of the door frame with alcohol or acetone. In those places where they touch, we glue the seal. In order to glue it evenly in the corners, we make an overlap of two sealant strips, carefully cut off at an angle of 45 degrees with a sharp knife or scissors, remove the cut parts, and press the edges of the seals tightly in the corner. We check the doorway for a draft.

Stages of plating an iron model

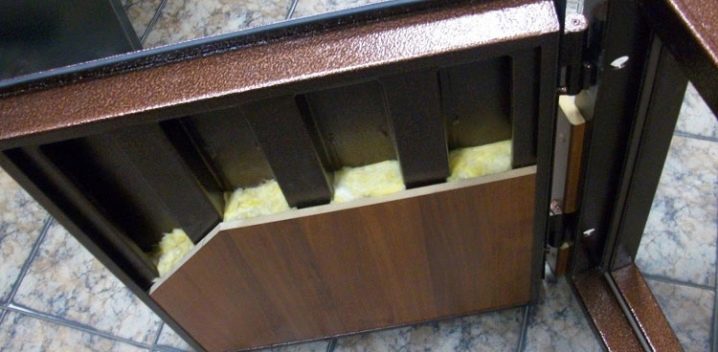

The sequence of actions when trimming an old door depends on its design. If the structure is more modern and metal panels are attached to the base with screws, the insulation is done internally. Proceeding to the internal insulation, we remove the metal structure, put it on the work surface. We unscrew the screws and remove the metal panel (so that the screws unscrew well, we lubricate them with machine oil). Using a tape measure, we take off the dimensions of the inner cells of the door.

We carefully measure the insulation material and cut it off. Be sure to cut out a place for the door lock and peephole. Styrofoam or foil-clad stone wool is great for old doors. We process the inner surface of the old structure with glue (liquid nails) and glue the prepared insulation. If there are gaps between the old door and the insulation, fill them with polyurethane foam. It is necessary to work carefully, squeezing out the polyurethane foam in small portions. It is important to ensure that it does not fall on the latch mechanism. For additional sound insulation, we lay foil isolon between the insulation and the metal sheet. We close the structure with a metal sheet and screw in the screws.

If the old door is made by fixing metal panels by welding, then we proceed to insulate the old door using an external method. We prepare wooden blocks 20 (30) x20 mm. We measure the parameters and cut the slats to the required length. Using a drill, we make holes for future fastening in a metal sheet. We assemble the base from the prepared wooden blocks and fasten it to the metal sheet with self-tapping screws.

We prepare insulation according to the specified dimensions. We line and glue the insulation into the cells between the slats. We fix the MDF panel or plate with screws. Additionally, for sound insulation from the outside or from the inside, you can treat the door with leatherette. To do this, we fold the leatherette and fix it with staples. Lubricate the lining and hem of the leatherette with glue (liquid nails) and press it tightly against the metal sheet. This work is painstaking. At the last stage, we install door locks, handles, peephole. We return the finished door to its place.

When sheathing a single-layer metal door, it is necessary to measure the cells between the stiffeners. Cut out the inner material to the specified size. Spreading glue the insulation in the cavity.We eliminate cracks and small gaps using polyurethane foam. We decorate with an MDF panel.

Improving the performance of Chinese products

The door made in China is a non-separable structure. To insulate it, remove the door, put it horizontally. We remove the handles, peephole, locks. Then we begin to attach the frame and stiffeners to it, both from the inside and from the outside. Therefore, we choose a wooden beam with a thickness of 20 * 20 mm, or more (we start from the thickness of the insulation material). If desired, you can weld a metal base, attach it with self-tapping screws or weld it to the door leaf, fill the joints with polyurethane foam.

The next step is to install the insulation. If fibrous materials (mineral wool, stone wool) are selected, lay out the water-repellent material by about 200 mm larger than the base cavity, fix it with glue (liquid nails) and line the cotton wool, after cutting out a slightly larger canvas than the size of the base cells, and cover with another layer of water-repellent material. The edges of the film are tightly tucked onto the top layer and secured with tape.

We cover the insulation with foil-clad isolon or foam foil with the foil-clad side into the room. This will improve the soundproofing qualities of the door. Polyfoam, expanded polystyrene, polystyrene, foil-clad isolon do not need waterproofing, since they themselves have water-repellent properties. Next, measure the distance between the stiffeners with a tape measure, cut the insulation a little larger than necessary to avoid the formation of a cavity between the insulation and the base of the door. We glue the insulation in the cavity with glue (liquid nails).

We coat the base attached to the surface with polyurethane foam at the joints. The next step is to decorate the structure with an MDF sheet or an alternative material. It is important to remember that the decorative panel must be fixed from the bottom up. We fix, put locks, peephole and handles, hang the door. The door now keeps the house warm and also protects against noise.

Without dismantling

Warming without dismantling is done in three ways. The first is suitable for metal doors with removable panels. To do this, unscrew the screws, starting from the bottom, moving up the canvas. We do not unscrew all the screws, we put the metal door on the stand. We carefully advance the insulation treated with glue (liquid nails), fix it. Foil isolon is suitable for this method. We screw in the screws. The door is ready.

The second method is suitable for solid metal doors. We make holes on top, after making sure that there are no more holes and gaps. We take any friable insulation (non-combustible bulk wool, granular foam, vermiculite, sawdust). We put it into the holes, knock on the door to achieve complete filling of the cavity. This method is completely unsuitable for doors with latch locks. After filling, we put plugs on the holes.

The third method is external insulation. We completely follow the step-by-step method of fastening with an external method. You can stick insulation on the inner surface of the doors.

Beautiful ideas

The appearance of the front door always emphasizes the status of the owner. Therefore, in a private house, the requirements are especially high. It is important to take care of a decent image here. The metal door market is saturated with a variety of products. The fact that the doors can be ordered according to a personal project is also encouraging.

And yet, how pleasant it is to work on the design yourself! We offer several ideas for decorating metal doors with your own hands. The design of the door in the apartment is interesting in that the outer side can be decorated so as not to attract other people's attention. The simplest, most affordable way is to decorate a metal door with bright fittings. Outside, you can attach new numbers, put stylized handles, hinges, locks.

For those who prefer natural materials, we can recommend gluing the inside of the door with MDF panels or simple wooden slats. The design and color of the metal door of a private house, as well as the shape, depend on the style in which the house or cottage is built. For fittings, you can use forged parts, use stained-glass windows, glass blotches. And instead of a modern bell, you can hang a knob, a gong.

The video below will help you insulate the front door yourself.

The comment was sent successfully.