What is a geomembrane and how is it used?

Geomembrane is widely used at some stages of construction. For each specific case, there is a special type of material, it all depends on the conditions in which it should be applied. In today's article, we will look at what a geomembrane is and where it is used.

What it is?

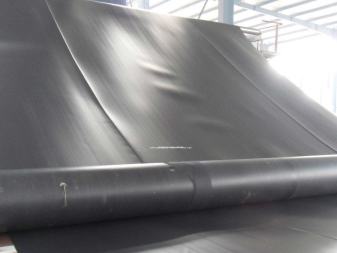

Geomembrane is a synthetic fabric that is completely waterproof. With its help, an obstacle is created to the penetration of moisture. Simply put, a geomembrane is dense polyethylene, which is very elastic, which allows it to be laid taking into account all the unevenness of the relief and buildings. It is highly durable and completely waterproof. These characteristics make it a versatile material that is used wherever needed. waterproofing.

The described canvas is very different from ordinary polyethylene. This is due to the substances and production technologies that are used in its manufacture.

The material of the described canvas is not ordinary polyethylene, but a composite, which is applied to a polyethylene base... The composition contains various substances that prevent the destruction of the material under the influence of the atmosphere and direct sunlight.

The permissible temperature range is +65 to -75 degrees Celsius. It is resistant to various aggressive substances of chemical and biological origin.

The web has a higher strengthif you compare it with polyethylene. With a material thickness of 0.3 to 3 mm, it can withstand long-term vertical loads, stretching in the horizontal direction by 550% without damaging the surface. These indicators may vary depending on the brand and manufacturer of the canvas. The service life of the coating is 50 years or more.

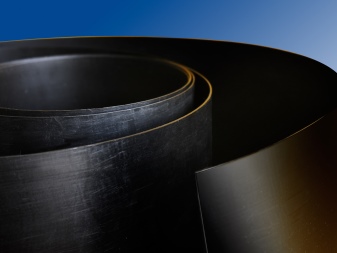

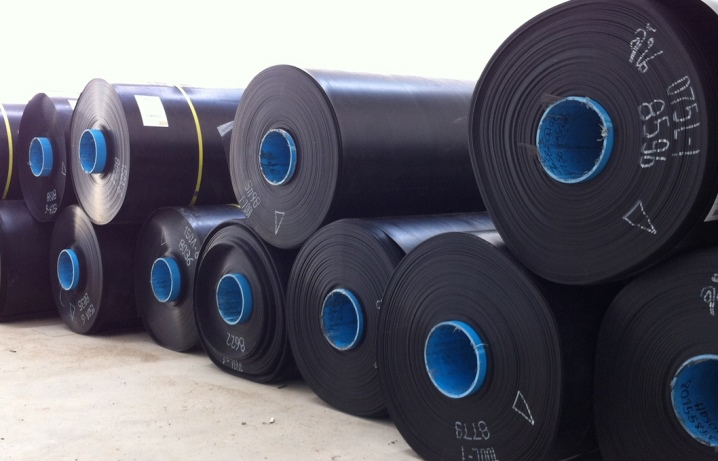

In production it is used continuous extrusion technology, which makes it possible to obtain whole sheets without connecting seams. The dimensions of the rolls of this product are up to 2.7 m wide, and the length is the same for all and is equal to 50 m. For joining the canvases to each other, a welding method is provided using a special hand tool.

Advantages and disadvantages

Let's consider the main advantages of the described product.

- Strength. It depends on the physical capabilities of the starting material that is used in the production of a particular roll. Based on this, we get a certain IPA indicator. In addition, the thickness of the material directly affects the degree of strength. Additional reinforcement of the web is provided by a reinforcing layer.

- Elasticity. The material stretches very well, especially if it is made of LDPE.

- Strength... These materials are capable of withstanding high ground pressure. They are not afraid of sharp stones and plant roots. This makes the geomembrane an excellent foundation protection. In this case, the likelihood of damage to the material during installation is extremely small.

- Chemical resistance. Materials made from polymeric substances are immune to aggressive chemical compounds (acids, oils, alkali). Due to this property, the described product can be used to isolate oil storage facilities, at toxic waste landfills.

- Environmental friendliness. This material is absolutely safe for human and animal health.

- Durability. As mentioned earlier, the lifespan of this material is very long.This is due to the fact that this canvas is not subject to destruction (corrosion, ultraviolet radiation, drying out).

- Temperature drops. The material is also immune to ambient temperatures. A wide range of operating temperature values allows the coating to be used both in tropical climates and in conditions of constant cold.

- Ease of installation... The film is not a heavy material, it is not difficult to work with it. The rolls are rolled out on the ground, and the material itself is very easy to cut. It is equally easy to install both in a small area and in large areas.

It is very difficult to highlight the disadvantages of such material, and they can rather be attributed to the difficulties of installation and terrain features, and not to immediate disadvantages. For example, thick, high-density membranes are less elastic than their LDPE counterparts. It's harder to work with them. They are used mainly on relatively flat surfaces.

Views

Waterproofing material applied in many areas of construction (foundations, ponds, agriculture). For certain purposes, the required type of the described canvas is used. Geomembrane can be divided into 2 types, namely:

- HDPE high density;

- Low density LDPE (polyethylene).

In fairness, it should be noted that there are several more types of membranes, but they are very rare and it is difficult to find them on sale, so we will take a closer look the most common materials.

- HDPE (HDPE). This material is made of low pressure polyethylene and has a high density. These membranes are highly durable, physically and chemically resistant. Such a film is tough to the touch. It is used to cover large flat surfaces.

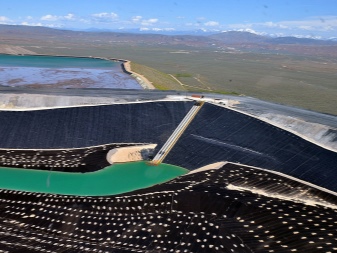

The product can be seen at construction sites of artificial reservoirs, reservoirs, storage facilities for liquid substances.

- LDPE (LDPE). A two-layer polymer web made from high pressure and low density polyethylene using an extruder. These membranes are very lightweight, soft and flexible. Due to these physical properties, the described material can repeat the shape of the relief. It is suitable for repeating the shape of canals, riverbeds, ditches. In this regard, such a membrane can be successfully used in the protection and preservation of water. It can work as an anti-seepage screen, it can be applied in geotechnics and for environmental protection.

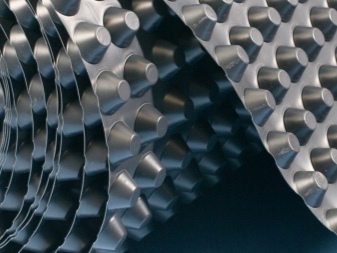

- Geomembrane with geotextile rolled onto it... In this case, the polymeric material is covered with a soft cloth from 1 or 2 sides. These 2 different materials combine with each other due to the high temperature. This type of membrane has increased strength and a rough base. The geotextile surface has a protective function. It prevents damage to the base material. The membrane, backed up with geotextile, is laid on a surface with sharp and hard edges (crushed stone, gravel). The material must be laid with geotextiles to the stones. It has a one-sided gluing method (TIP-5/1) and two-sided (TIP-5/2).

How is it used?

Waterproofing coating is used very often. Such a product used for construction. The profiled membrane has proven itself very well as a waterproofing basement and protection from the roots of various plants that are planted along the house. Due to its elasticity, ease of soldering 2 fragments and reliability from leakage of the connecting seams, it works as a full-fledged bowl to protect the basement from groundwater on the site and atmospheric precipitation.

In addition to protecting against the ingress of water into the basements, it can become a good bowl for an artificial reservoir... If you have a desire to make an artificial pond at your dacha, then you cannot do without such material as an extruded geomembrane.

It will not allow water to go into the ground and mix with the ground, which will certainly lead to deterioration of the water composition.Depending on the depth of the pond, fish can live in it all year round.

The small pond in the backyard is not limited to this material. With its help, you can create huge reservoirs and ponds. This material is a real find for fish farms. By digging a large pit in the ground and pouring water into it, you can avoid the ingress of substances that can negatively affect the health of pond fish. In addition to good performance, draining water from the reservoir, the membrane can be easily cleaned with a conventional high-pressure washer from accumulated contaminants.

In agriculture, this material is used to cover the walls of manure bins. The walls of fire reservoirs are finished with the same material. The drainage system is carried out with this cover. The extruded plastic membrane is used as a base for pouring a foundation to distribute a large weight of concrete.

Due to its resistance to acids and other aggressive compounds, solid waste landfills cannot do without such a canvas. There are many more industries in which this material will come in handy.

Manufacturers

Russia has its own manufacturers, for whom the geosynthetic membrane is the main product. Let's consider the most famous of them.

- "Anikom"... A Russian company that produces high quality products that are not inferior to foreign counterparts. In production, only high quality raw materials are used, which allows the products to meet all the requirements of GOST. The described enterprise produces both types of geomembrane (HDPE and LDPE). Thanks to this, the company is able to fully meet the requirements of consumers and prevent a shortage of goods on the local market.

- Geoflax. This company has at its disposal a whole plant that produces both types of geomembranes under its own trademark. The company's products have a smooth and even surface, completely protected from moisture. It has all the same properties as any other membrane. 1 conveyor can produce up to 500 tons of finished products per month.

- "PromGeoPlax". It is considered the leading manufacturer of geomembranes in the Russian market. The described plant produces membranes of all types and supplies its products not only to the Russian market. The company's extensive experience, first-class equipment and qualifications of employees allow us to produce large volumes of high quality goods.

Installation features

PVC membranes are considered to be durable. This is true, but only with proper installation. The most important thing is to properly lay the material itself. It should overlap. Before starting work, you must have a correctly calculated plan for laying all the material.

The web is laid exclusively by hand using a special welding tool. It is important to remember about the temperature outside and weather conditions. The laying of the material should not take place with a wind force of more than 5 m / s. At the same time, the air temperature should not be higher than -5 and higher than +40 degrees C. Do not lay the membrane during rain or immediately after it.

It is advisable to lay the canvas on a cleaned homogeneous surface. All foreign objects must be removed from it in advance, especially plant roots, sticks, boards, glass and any other debris that can damage the material under pressure. The cleanliness and uniformity of the coating play an important role in the life of the coating to be produced.

The method of attaching a geomembrane to a concrete wall is fundamentally different from laying it on the ground. The fastening of the canvas to the wall is carried out with anchor bolts, which are closed on top with a textured polyethylene patch. All seams must be well soldered over a large seam width. The quality and durability of the entire structure depends on how correctly the installation of this type of insulation is performed.

Therefore, such work must be performed by high-level specialists.Otherwise, the welds will be leaky and the textured polyethylene membrane will not do its job.

When welding 2 sheets of geomembrane, you need to know some features.

- The sheets are joined together by high temperature welding. This method is called extruded and is performed with a special tool.

- After completing the main stage of welding, begin to fix the edges.

- The final consolidation takes place in prepared trenches.

- It is desirable that the overlap of the sheet is at least 10 cm from the edge. This will create a wide and secure seam. In this case, there will be a small overspending of material, but it is better to sacrifice 1 extra roll than after the completion of all work to look for one leak in multi-meter seams.

A video overview of the geomembrane is presented in the video below.

The comment was sent successfully.