What is microcement and how to use it?

Relatively recently, the construction market has been replenished with a material called "microcement". The word "microbiton" is a synonym for the term. And many have already appreciated the excellent properties of the material, among which the main ones are ease of application and high wear resistance. Even a person without any experience in repair can work with decorative plaster.

What it is?

Microcement is a dry mix based on cement and finely ground quartz sand. The liquid that transforms the material is a polymer solution. It also makes the plaster a material with high adhesion, bending and compressive strength. An obligatory component of microcement is a protective varnish, because it closes the pores of the composition, protects it from water, and takes on the loads of operation.

In other words, microcement is a polymer-cement plaster, which is covered with several durable layers of varnish.

If the product is made on a white base, it can be quickly tinted with dry pigments. That is, it is not necessary to expect that such plaster will be strictly gray - there are options.

The advantages of microcement.

- The material exhibits excellent adhesion to most surfaces. Unless he will "make friends" with glossy tiles. The tile will have to be rubbed thoroughly until it becomes dull.

- Microcement is a very thin material, its layer is no more than 3 mm.

- Plaster a priori has the strength of a stone, and a protective varnish only enhances it. Thus, it is possible to form the structure of self-leveling floors that will not be afraid of abrasion.

- Stylish material allows you to bring design ideas to life, especially when you want to do something in loft aesthetics and related styles.

- The material is completely fireproof, and is distinguished by its resistance to heating.

- This is a good solution for initially weak substrates - the material strengthens them perfectly.

- When you touch it, you do not get that very "cold feeling", because it is not really concrete. In short, what is needed for a home interior in terms of visual and tactile sensations.

- It is easy to clean: plain water + mild detergent. Here are just abrasive compositions will have to be abandoned.

- Microcement is a moisture-resistant material, therefore, it can and should be used in bathrooms, toilets, in the kitchen. Seamless micro-concrete is also used on building facades.

- There won't be a lot of construction waste - if specialists work, everything will be cleaner than the client usually thinks.

- Since microcement has superelasticity, it is not afraid of vibrations, and the shrinkage of buildings (which residents of apartments in new buildings are afraid of) is also not afraid of it.

- No mold, no fungus - all this simply does not take root on this material. For rooms with high humidity, this plus is difficult to overestimate.

Disadvantages of the material.

- It's not so easy to work with him. The mixture is kneaded in a polymer solution, and the exact proportions are extremely important. Time to work is also limited: if the composition contains epoxy components, it will last no longer than 40 minutes. Docking of some areas is carried out according to the principle of "wet on wet", it is necessary to have time before the plaster has set. That is, it is very difficult to work alone, you need a team of 2-3 foremen.

- Micro concrete will simply collapse without varnish. The polymers in the mixture make it strong and plastic, but still they will not provide adequate protection against water penetration, as well as abrasion resistance.Therefore, several layers of varnish are a mandatory step, albeit partly troublesome. But, in truth, even the varnish will wear off over time. Restoration will be needed.

One of the main attractive properties of the material, which puts an end to the choice, is the seamlessness of the resulting coating.

The material is both industrial and decorative. The texture is very interesting, it is as close to concrete as possible, but still smoother. That is, it is visually more attractive than concrete.

Areas of use

Micro concrete is used as a finish for exterior and interior work. This is a great option for walls that are under stress. But the floor, facing of columns, decorative portals in the interior deserves such a utilitarian decor equally.

Attention! The wear resistance of microcement is superior to that of laminate, tile, parquet and marble. As a floor covering, this decorative plaster is second only to porcelain stoneware.

This will be a new and unbreakable solution for updating the walls in the bathroom, and if the bathroom is large, then even the countertop and window sill (the window can be in a spacious bathroom) can also be decorated with micro-concrete. Used material in the shower, for wall decoration in the hallway. The color can be chosen so that there is harmony with furniture and decorative items.

The use of micro-concrete is not only for decorative needs (although these, of course, prevail). The material is used in underground construction and well workover. It covers almost any solid base, it can be reinforced and used when installing a "warm floor" system. The material is applied exclusively by hand. This is the only way to create attractive water spots, which are the best tool for simulating the natural look of the coating.

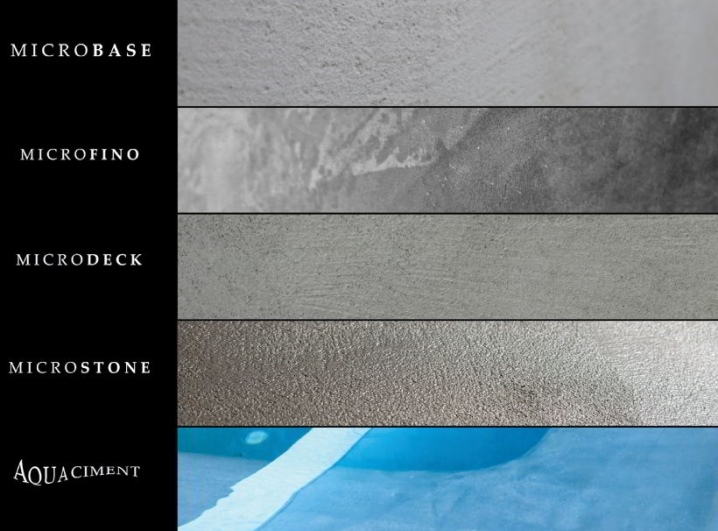

Description of species

All types are divided into one-component and two-component. In the first case, only water is required to mix the solution. Resins (including acrylics) are already in the composition of the cement. And in two-component forms, the user needs to independently combine the liquid resin and dry powder.

- Aquacement. In the composition of this product, there must be special moisture-resistant components that enhance the composition of the substance, protect decorative plaster from chlorine and salts. It is convenient to treat the walls of swimming pools, bathrooms and saunas with such micro concrete. In a word, all rooms in which there is a high level of humidity.

- Microdeck. Of all types of microcement, this one is the most durable. They are poured into floors in those areas that are experiencing the highest stress. The structure of this type will be larger than the structure of standard microcement.

- Microbase. If the task is to decorate the floors in a rustic style, this material cannot be found better. It is deliberately rough, rough - what you need for a rustic. Microbase is also suitable as a base for any topcoat.

- Microstone. This decorative plaster consists of cement with a coarse texture. When the mixture dries, the coating is very similar to natural stone. A good, budget solution for those who do not mind high-quality imitations.

- Microfino. This type is mainly used for wall decoration. It is a decorative plaster with a very fine texture, one might say, graceful. Today, this option is often used in studio apartments, in spacious hallways. Inexpensive, reliable, textured.

Top brands

Navigating the best microcement brands in different collections and reviews can have significant differences. And that's okay. But there are manufacturers whose brand runs from review to review.

- "Reamix". It's nice to include production from Russia in the list. But it turned out to be true here. Although the company itself can position the product as a putty. This does not change the essence, because the word “putty” is accompanied by the qualifications “decorative” and “two-component”.The product is sold in two different packages: in the first - a mixture for solution, in the second - a pigment.

- Edfan. The manufacturer from Latin America is also pleased. He is one of the flagships in the micro-concrete market (possibly the first manufacturer). Therefore, microcement is often called the name of this brand, without even realizing that this is the name of the company, and not the name of the material itself. The brand's reputation is impeccable.

- Senideco Senibeton. This is a "open and use" product. The company sells the mixture in 25 kg buckets. The material is white, but can be painted in any color by adding dry or liquid pigment. The brand aims to create a coating that completely imitates concrete.

- Stoopen & Meeus. The Belgian manufacturer sells microcement in 16 kg buckets. To obtain the desired color, a pigment is added to the solution.

The surface does not need to be primed before applying this product. Time to work with the mixture - from 3 hours (no more than 6 hours).

- Decorazza. The brand sells a fine-grained material that forms a seamless and moisture-resistant coating that resembles concrete. You can decorate both walls and floors and even furniture. The brand's catalog contains two dozen modern shades.

It is possible and necessary to look closely at little-known manufacturers: they may not yet have enough funds for advertising coverage, but the product is already cool. Be sure to check the certificate of conformity.

Application stages

Work begins with the preparation of materials and tools. This list will include:

- special primers - if there is a desire to play it safe, prevent capillary suction or blocking the vapor barrier;

- two-component polyurethane-based varnish;

- impregnation for layer-by-layer connection;

- rubber trowel - the composition is applied and smoothed with it;

- spatula-sponge - indispensable for leveling layers;

- a trowel made of stainless steel, having a beveled edge and rounded edges - it is applied and leveled with it;

- brush with natural bristles - if you need to apply a primer to the ceramics;

- short nap roller for varnishing;

- mixer.

Microcement application technology in stages.

- Preparation. If we are talking about a field, you need to strengthen the surface of the base, reinforce the edges of the steps. The main thing is that the surface does not raise questions about strength, it is even, without drops and cracks more than 2 mm. There should also be no stains on it, as well as dust, traces of rust. The base must be primed and dried twice. Stone, cement, concrete, as well as brick must be moistened before applying microcement. Tiles, porcelain stoneware and lamination surfaces are degreased and cleaned. Particleboard and gypsum plasterboard are primed with compositions with sand.

- Application. If this is a floor, you need to do this: there will be 3 layers in total. The first is a crack-resistant reinforcing mesh, base micro-concrete and polymer. The second and third layers are decorative microcement, color scheme and polymer. Walls and ceilings are not always reinforced. The base layer for them is a continuous puttying (as they say, "on the spot"). And the finishing layer is smoothed out with a metal tool. You can smooth it both wet and dry. You can grind and polish with abrasives.

- Finishing finish. This is the application of varnish. Instead, special functional impregnations and waxes can be used.

This is a general outline. And now about how to act technically, if you have never done anything like this before.

Step by step plan.

- The surface is prepared, primed if necessary, the composition is mixed.

- A thin base layer is applied to the surface with a trowel, no more than 2 mm.

- A dry spatula-spatula evens out the surface. They are once again traversed over the layer with a metal trowel - so that a small pattern begins to appear.

- After an hour, the surface is smoothed with a wet sponge. And again leveling with a trowel, but without polishing (fraught with the appearance of dark spots).

- After a day, you can walk on the surface with a grinder.

- The surface is thoroughly rinsed with water and wiped off. For a day, she must be left alone.

- Time to apply a protective sealant to the surface - do it with a roller.

- After another 12 hours, the varnish can be applied. This is usually done with chaotic wrist movements.

This instruction is universal, but each specific case may require adjustment. You should always read the instructions that the manufacturer prescribes on the packaging.

If the finishing is carried out in rooms with a high level of humidity, there will be one more item in the instructions: after laying the second decorative layer, sanding it and dusting it after drying, the surface is treated with a waterproofing layer.

For information on how to apply microcement, see the next video.

The comment was sent successfully.