What is Cement Milk and How to Prepare It?

Cement milk has long been actively used in the construction industry. If cement, sand and water are required to prepare a solution for a screed, then sand is not used to create cement milk. It should also be noted that the proportions are not regulated by any normative acts and documents.

Peculiarities

You have probably noticed that after using the cement mortar, a film forms on the surface of the concrete, which visually resembles gray water. It is she who is the cement milk. This liquid negatively affects the strength of the finished coating, so it must be removed immediately. After drying, a crust will appear on the concrete, which will adversely affect the adhesion of the concrete base to other coatings.

If you do not remove the cement laitance, but immediately start painting, then be sure that your work will last no more than a year. In the near future, the paint will begin to crumble and flake off. This is due to the fact that the cement laitance prevents the penetration of paint deep into the concrete, which is why, regardless of which finish you choose, it will last relatively shortly.

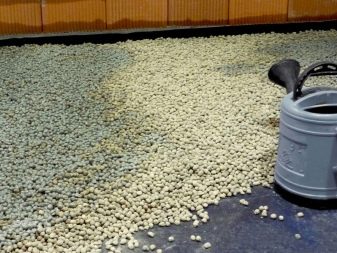

However, cement milk also has significant positive characteristics. The often considered solution is used to create floors, attic floors and roofs, which are insulated using expanded clay. This material consists of many granules that differ in size and weight. Based on this, some granules that find themselves in a liquid medium try to rise to the surface, and the strength of the backfill decreases.

Expanded clay gravel, which has been laid and leveled, should be covered with a layer of cement laitance a couple of centimeters thick. This layer is necessary for the implementation of protective functions, and it also acts as a reliable base for other coatings. It is important to note that the cement laitance penetrates deep into the backfill, affecting even the lighter expanded clay granules.

In order for the backfilled layer to acquire a structural form, it will be necessary to mix one part of cement and 2 parts of water. You can make a similar solution yourself. This mixture perfectly penetrates through the backfill, treating all expanded clay granules and enveloping them with a film of binder. After the cement milk dries well, the expanded clay layer will acquire additional cohesion. This backfill is now suitable for screeding.

Advantages

It should be noted that white cement milk has disadvantages only if it was formed naturally on a concrete base. If the mixture is prepared for any kind of work, then it has a fairly large list of advantages.

The advantages of cement milk are:

- reliability;

- thermal insulation;

- soundproofing;

- waterproofing;

- high speed of solidification;

- quick and easy styling.

With this mixture, deformation of the upper concrete and reinforced concrete layers can be prevented. They just need to be thoroughly spilled with this solution first.

Application area

The solution in question can be used for:

- elimination of small cracks and chips in the base;

- pouring a layer of expanded clay, which makes it possible to impart heat-insulating properties to the coating;

- to strengthen the underlying layers when creating a foundation;

- patching up various damages that are formed in old concrete;

- processing of metal containers, since milk increases anti-corrosion properties;

- to level the surface.

In addition, cement milk can be used in other situations:

- used for fixing bedding under the covering of the beams;

- allows you to reduce the porosity of various surfaces;

- can be used as a process fluid when using concrete pumps, etc.

Milk consumption per 1 m2 of cultivated area is directly related to the purpose of its use. The cost of 1 m3 depends on the proportions of the constituent components.

Cooking technology

The process of preparing the milk in question is quite simple. Based on the expected amount of work, the required amount of cement must be calculated and measured. Remember that the amount of water should be 2-3 times greater than that of the cement powder. Then you need to do the following:

- Add a little water to the cement, stirring the mass thoroughly and bringing it to a homogeneous state.

- Remember to stir, gradually add water to make the solution more fluid.

- If for some reason you do not have the required amount of cement, then slaked lime can save the situation. It can replace a small part of the cement powder.

In some cases, a primer is used to create milk, which acts as an additional component. To prevent lumps from appearing during the preparation process, it is worth passing the cement through a fine sieve. Thus, there will be no lumps or debris in the powder.

As noted earlier, the composition of the cement slurry is not controlled by regulatory documents, so everything depends on the specific situation.

There are several common recipes for preparing the mixture in question.

- If you need to seal cracks with mortar, then cement and water must be mixed in a 1: 2 ratio.

- To strengthen the screed, the amount of cement should be no more than 1/3 of the total amount of the mixture. The weight of one liter should not be too heavy.

- Equal proportions are required in order to carry out the laying of an interlayer under the foundation.

- For pouring expanded clay, the mixture should have a more liquid form. Therefore, water is needed 3 times more than the amount of cement.

- If wall decoration is being carried out, then we mix water and cement in a ratio of 1: 3, and it does not matter whether the decoration will be carried out inside or outside the room.

Based on the possible mixing options, cement laitance can be presented in various variations in consistency. It can be in the form of a suspension, or it can look like a batter. You can also find a mixture in the form of a suspension.

For thorough mixing, it is recommended to use a drill with a special attachment, otherwise there may be clots in the finished milk. It is possible to increase the plasticity of the prepared mixture by adding slaked lime, which was already mentioned earlier. The consistency spill should be like liquid glass.

To obtain cement laitance of optimal consistency, it is important to use three times more water than to prepare a mixture for screed. To achieve the desired effect from using the solution, it is necessary to achieve optimal density.

To check this parameter of the material in question, we perform the following steps.

- We carry out pouring of a small part of the space covered with expanded clay.

- We are waiting for 20 minutes.

- We observe the results of the check.

- If the solution has completely penetrated down, and there are no traces on the surface, then the milk turned out to be excessively liquid.

- If almost all or most of the solution remains on the surface, then in this case it is necessary to add more water.

- The best option is one in which most of the liquid will seep through the pillow, but a small amount of laitance will remain on top.

Deleting

If cement milk appears naturally, then it must be removed from the surface. To remove unwanted film, you can use one of the following methods:

- Mechanical way. It provides for the use of sandblasting or crushing machines. This removal technique is quite costly and difficult to implement. Nevertheless, the use of special equipment will allow you to remove cement laitance even from hard-to-reach places. Mechanical cleaning can be done using conventional metal brushes, but in this situation it will take a lot of time as each area will have to be manually cleaned.

- Dry cleaning, which involves the use of special solutions containing acid. With their help, you can remove unwanted film as soon as possible. However, the negative side of this method is that the tool, simultaneously with the removal of plaque, negatively affects the concrete itself. It is necessary to resort to this method only when mechanical cleaning has proved to be ineffective.

It is possible to neutralize the chemical composition used to remove cement laitance using concentrated alkali. After carrying out these procedures, the surface must be thoroughly rinsed.

What is cement milk, see the video below.

The comment was sent successfully.