Features of fit bolts

Any mechanism and each structure consists of many separate parts, for which fastening into one integral product, specially designed fasteners are used. One of these is the bolt. This is probably the most popular and well-known fastener, which is widely used both in production and in everyday life.

There are a lot of types of such products. In this article, we will tell you in detail about tight-fitting bolts, their features, areas of application, types and features of installation.

What it is?

A fitting bolt, or, as it is also called, a precision bolt, is a special fastener that, due to its excellent physical and technical characteristics, creates a very strong and reliable connection between individual structural parts.

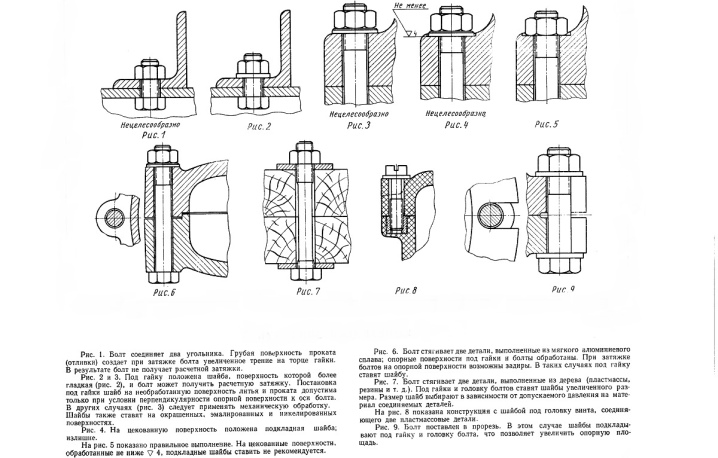

This type of bolt, like all its analogues, is usually used together with a nut, washer.

The product is widely used. This is due to a number of features and advantages that are inherent in such fasteners.

- For the manufacture of the bolt, only high-quality steel grades 35X, 40X, 45X are used. Its choice depends on the purpose of the product, on what materials it will hold together, what kind of load it will need to withstand.

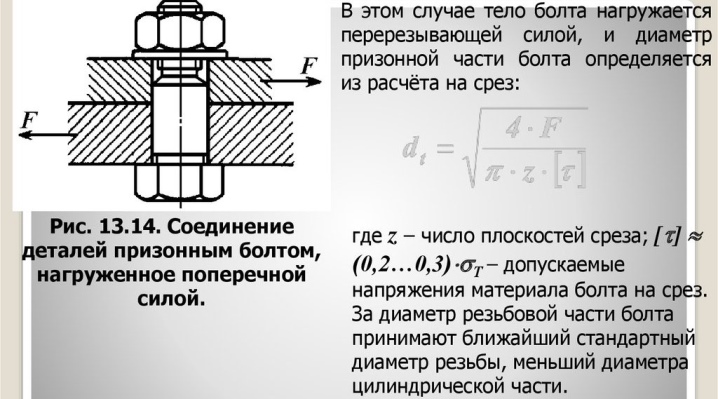

- During the installation process, the fasteners are placed in the hole, thereby creating a gap-free connection.

- The use of fit bolts with a turned, ground thread, which is characterized by strength class A, guarantees a strong and reliable connection between the parts.

- Each product, before receiving a quality certificate, necessarily goes through a hardening stage, due to which its properties and parameters are enhanced.

The main advantage of the close-fitting bolt is its ability to withstand very high loads: static, cylindrical and even shock.

It should be noted that it is characterized by a long service life, wear resistance, and mechanical stability.

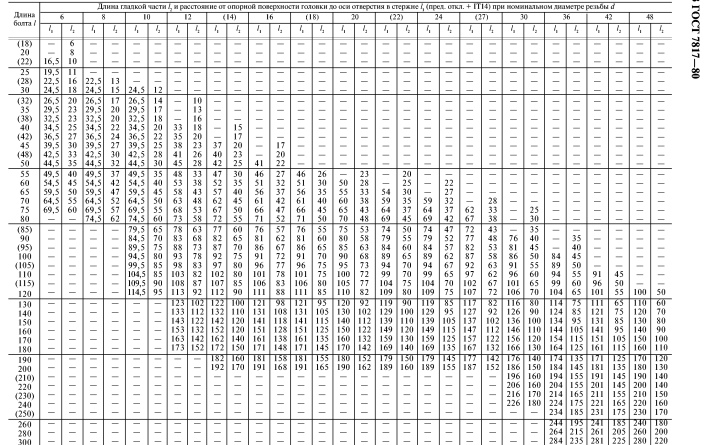

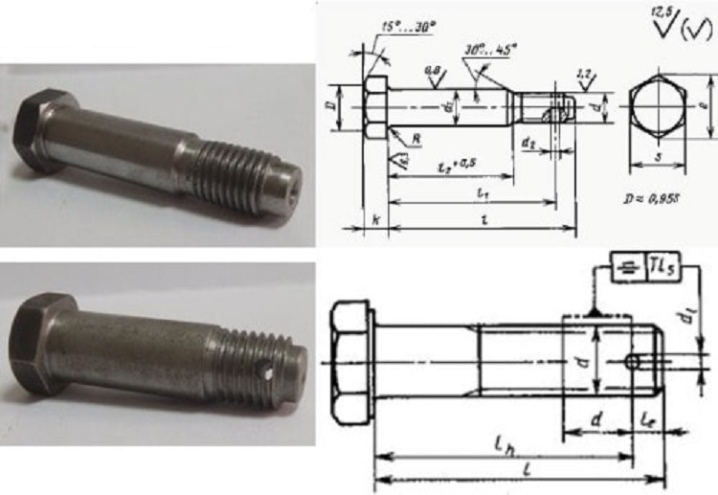

Such fasteners are manufactured in accordance with the standards specified in GOST 7817-80 “Bolts with a reduced hexagon head of strength class A for screwdriver holes. Design and dimensions ".

Applications

Despite the fact that the bolt itself is quite compact and its dimensions are small, it is very strong. That is why it has found wide application both in manufacturing industries and in everyday life.

Fasteners are used both in the process of installation work and in construction:

- during the construction of the metal frame of the building;

- for fastening metal trusses, consoles, hinges, flanges, beams;

- in the process of installing facade panels;

- during the construction of the roof, to secure all its individual elements;

- when installing cover and floor panels;

- during the creation of new equipment.

It can be concluded that a close-fitting bolt is a mandatory fastener if the structure to be created will have to withstand extremely high constant loads.

Today, this fastener is widely used in industries such as mechanical engineering, shipbuilding, metallurgy, and the oil industry.

What are they?

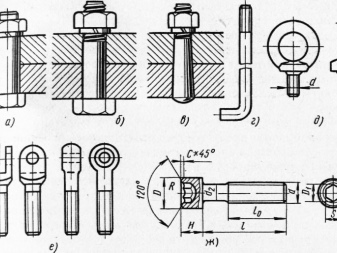

The assortment of fasteners, including tight-fitting ones, is varied. They can differ in purpose, size, parameters. There are several basic classifications of fit bolts. The product is classified according to:

- thread diameter - from M6 to M48;

- strength class - 5.8; 8.8; 10.9;

- type of installation - a clamping bolt for a sleeve or for a hexagon, each of them can be mounted using a special tool.

Today, the most popular are high-strength tight-fitting bolts with thread diameters M10, M12, M16, M30.

How to use?

It is necessary to use a tight-fitting fastener only for its intended purpose and if such a fastener is necessary. The first step is to choose the right fasteners, taking into account:

- its technical parameters and main characteristics;

- the amount of load that the product will withstand;

- manufacturer and cost.

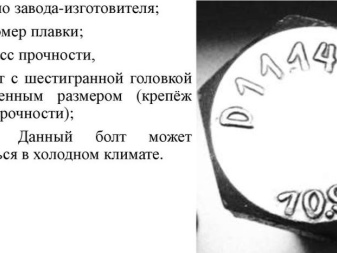

And the presence of marking is also important. This is brief but complete information about the product. Its presence indicates that the fasteners were made in accordance with the requirements, passed all laboratory tests, after which they received a quality certificate.

Mounting the bolt is quite simple and does not take much time. The base of the bolt is simply placed in the hole that was designed with a screwdriver, and then, using a special wrench or tool (it depends on the type of bolt), it is screwed, connecting the structural parts.

How to make a tight-fitting bolt with your own hands, see below.

The comment was sent successfully.