What are rivets and how to choose them?

Welding is a high-quality and therefore common type of surface connection, but its use is not always possible. Alternatively, you can use rivets, which are available in many types and are made from various materials. Let's take a closer look at what rivets are and how to choose them.

What it is?

Rivets are fasteners that are used to connect two or more surfaces of materials when needed. These devices are inserted into the holes of the workpiece, which have been formed in advance in the form of a line. The fastening element has the form of a rod, which, when deformed, is able to embrace the walls of the hole and hold onto them with the help of friction force.

According to consumers, rivets are reliable fastening methods that have been used for many years. Nowadays, they are also in great demand, in particular in those places where fasteners must be made as responsibly as possible.

With the correct selection of this device, you can count on the fact that it will be able to withstand a load similar to welding.

The advantages of using this type of connection are as follows:

- simplicity of design;

- the ability to connect materials of different types;

- reliability;

- resistance to vibration and shock loads.

The negative aspects of such fasteners include the following:

- the need for labor and material costs;

- the possibility of destruction of the connection with the wrong selection of the hole diameter;

- decrease in the quality of tightness after a certain period of time.

Riveting is the procedure for joining parts by forming a series of rivets. In this case, the connection is called a riveted seam. Depending on the hardware, the craftsmen can carry out hot and cold riveting. The first involves the use of a plastic material, but the second is usually based on the use of a hard type of steel.

Basic properties

A rivet is considered to be the type of connection that is more reliable than screws and screws. And this device takes up a minimum amount of space and is almost invisible after use. The rivets are lightweight and are usually used when there is no plan to disconnect the surfaces. Most often, riveting is used where welding for some reason is impossible or where non-welded surfaces need to be joined.

You can rivet not only metals, but also fabric products, all kinds of accessories. And also consumers say that a screw, bolt and nut can loosen over time, which cannot be said about a rivet. It tends to plant tightly and does not come out even if the metal is damaged.

What are they?

Rivets can be not only combined, blind and tight, but also made of a specific material. The technological features of these devices may have various features, which each manufacturer has its own. New types periodically appear on the market, for example, semi-hollow, so the consumer can choose driven, hollow, explosive, countersunk, colored and black, pull rivets. And also a wide range of fasteners allows you to choose the right option for metal, profiled sheet, profiled steel deck.

Currently, craftsmen use such types of rivets as:

- reinforced - these fasteners are used to connect materials with a high strength boundary, as a result of using these products, a very reliable connection can be obtained; this type of rivets has found its place in mechanical engineering, aviation;

- petal - such fasteners connect plastic materials, for example, wood slabs, chipboard, plastic;

- spacer - used when installing delicate and soft material;

- stainless steel - stainless elements are considered reliable and do not corrode for a long period of time;

- nut rivets do not need to pre-form holes in the workpieces; they have found their application in furniture construction and construction;

- multi-clamp have a direct resemblance to exhaust, but their use is considered especially relevant when it is necessary to connect materials of great thickness;

- plastic - polyamide fasteners are characterized by a fairly high level of reliability, they practically do not differ from screw fasteners, but at the same time they have good moisture resistance, they do not corrode and do not conduct electricity; Usually plastic fasteners are used when working with plastic, cardboard and fiberglass;

- terminal devices create a contact connection for electrical networks; they are made from materials that conduct electrical current without difficulty;

- cassette belong to an independent type of rivets, they are attached, like pull-out rivets.

Regular

One of the first rivets is considered ordinary, they are characterized by a mushroom shape. This type of fixture has a shank with a wide head. Rivets of this type are quite reliable, but at the same time they are characterized by complex installation. The use of this fastener is relevant in the case when it is necessary to connect two surfaces by fixing a through rivet.

After completing the work, a fungus is visible on one side, and a millimeter rod on the opposite.

Fume hoods with tail

The use of pulling devices is in demand when joining two metal sheets. These fasteners contribute to secure fixation, even if the master has access to only one side. In order to work with blind rivets, an air or mechanical pistol is required, and you can also use a special attachment for a screwdriver.

The exhaust type of devices has the form of a long metal rod, at the end of which there is a tubular aluminum sleeve. It is also possible to use other soft material in the manufacture of these goods. By pulling the steel rod, the craftsman can detect the deformation of the sleeve rod, the reason for this situation is the presence of a small head, which prevents the exit.

The popularity of blind rivets is due to the ease of installation, as well as the low cost of equipment. This fastener is appreciated for the ability to connect thick and thin parts, even if the sleeve height is low relative to the thickness of the workpieces. Insert the workpiece and then tighten the tail. As a result of these manipulations, you can get a full-fledged reliable connection.Exhaust hardware are of two types.

- Open Are standard devices that have a through hole in the body. They are quite similar to hollow goods. They are used in the case when high requirements are not imposed on installation regarding reliability and strength. Such products are among the most demanded goods on the market.

- Closed used in the case when the fasteners must be as tight as possible. These rivets prevent moisture, dust and debris from entering the fasteners.

Threaded

Threaded rivets are among the most expensive. This fastener is in the form of a hollow threaded sleeve.The sleeve is inserted into the prepared hole and the rod is twisted. Usually, these devices are made of aluminum, but there are products made of copper and brass. For a high quality connection, it is worth not violating the direction of the pull. The work should be done with a special pistol, but, alternatively, you can use a bolt and nut. This type of rivets is characterized by minimal trauma. Often, the threaded form of rivets is used during the mechanical engineering process, as well as during the manufacture of the body part of electrical equipment.

According to the design features, this hardware is divided into many varieties. For example, the spacer option holds soft and loose surfaces well. The multi-clamping product comes in handy when working with parts of different thicknesses. In this case, the formation of a universal node occurs.

Materials (edit)

Typically, the rivet material should be the same as the blank, thus reducing the possibility of corrosion. The materials from which these metal fixtures are usually made are as follows:

- steel - metal can be used in several varieties, namely: usual - these are brands St2, St 3, ST 10; corrosion-resistant - Х18Н9Т and galvanized; steel fasteners are used in cases where high reliability of fasteners is required;

- copper in the form of MT and MZ - copper is often used for the installation of copper roofing and sheets of this metal;

- Aluminium alloy - these rivets are characterized by plasticity and low weight; they are often used in mechanical engineering, aircraft construction, the manufacture of equipment and computers;

- brass L63 - brass rivets have a rather attractive and neat look; they look good during interior decoration, premises and even transport, including marine;

- aluminum and magnesium;

- plastic - this type of rivets is made of polyamide, so the products are characterized by strength and long service life.

When joining copper products, you can use brass and copper rivets. Steel sheets are connected exclusively with steel fixtures. On sale you can often find fasteners that consist of an alloy of aluminum and steel.

Galvanized rivets are a suitable option for installation on a facade, slope, ebb, metal tile, profiled sheet. Usually they are painted to match the details.

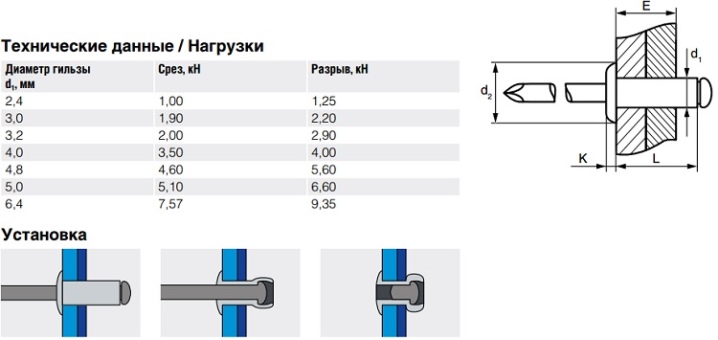

Diameter and length

The dimensions of the rivets should be selected in accordance with the thickness of the materials that will be joined. In this case, the most important parameters are the length and diameter of the rod. According to the diameter of the drill, the master is determined with the drill that he will need for work. The diameter of the rivet rod can be from 1 to 36 millimeters.

The length of the rivet material ranges from 2 to 180 millimeters. It should be remembered that a large diameter does not always indicate a good connection reliability. The shape of the hardware can be varied, for example, round, hexagonal, cylindrical.

Selection Tips

Since there is a wide range of fasteners on the market, it is not always easy for the consumer to choose the ideal option for himself. Sometimes the craftsmen have questions about how to choose rivets according to the thickness of the material to be fastened, to give preference to hollow, with a semicircular head or decorative goods. In order to make the right choice, it is worth considering 3 main parameters: length, diameter and material of manufacture of the product.

Initially, attention should be paid to the material from which the rivets are made. For example, aluminum cannot be used with materials that are prone to corrosion. If it is necessary to fix the shield grounding or any other conductive object, then in this case it is worth buying brass products.

The second very important indicator for rivets is their length. Securing an element that is too short will not give good strength and reliability of the connection. And the long length of the rod will entail inaccurate fixing of the surfaces. An ideal purchase is a rivet that is 20 percent longer than the aggregate surfaces.

Do not ignore the diameter of the rivet and the hole that was made for installation. With a significant difference in indicators, a poor filling density and a minimum friction indicator will result. With such an unreliable fastener, the rivets are pulled out even under low load. The durability of the use of hardware is influenced by the environment of use, as well as the correct selection.

In food and chemical plants, where equipment is exposed to high stress, it is better to use stainless steel.

Usage

In order to install the rivets, you will need to complete several steps.

- First of all, using the tool, a hole is formed into which the rod will subsequently be inserted. The calculation of the size of the hole is carried out taking into account the fact that it should exceed the volume of the rod by 10-15 percent.

- The hardware must be immersed in the hole so that the head is visible on the back of the structure. Installation of threaded elements can be done with a hand riveter. Spacer and explosive types of products are fixed using an electric or piston tool.

The main areas of use of rivets are considered mechanical engineering, shipbuilding, construction of buildings, ventilated types of facades, the formation of playgrounds, as well as decor fasteners. When fastening heavy objects, this type of hardware is not used. Experts recommend buying flexible yet durable products such as carbon steel, aluminum or copper.

Despite the fact that the process of fixing rivets is quite laborious, it is still one of the most popular. According to experts, in the coming decades, craftsmen will not abandon the use of these hardware.

In the next video, you will find making rivets with your own hands from colored materials.

The comment was sent successfully.