Fastening the lining to the clamps: the subtleties of installation

Sheathing of internal and external surfaces in a room with clapboard has been used for a very long time and does not lose its popularity. Decorative boards are used for finishing baths, saunas, verandas and terraces, gazebos and balconies, rooms in country houses, even utility rooms and garages. The invention of kleimers greatly facilitated the installation of the lining.

What it is?

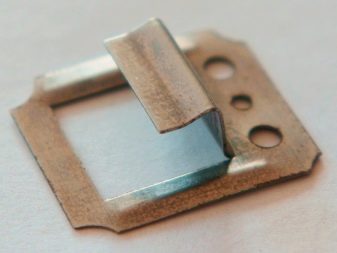

The rooms are sheathed with high-quality boards for beauty, practicality and environmental friendliness. More recently, everything that was created from wood was simply nailed to surfaces or screwed in with self-tapping screws. But progress does not stand still. A special device, similar to a bracket with a hook and holes, has appeared in order to improve and facilitate the installation process - a kleimer. Nails and other hardware will also be involved, but for different functions.

Advantages and disadvantages

The use of clamps has a number of significant advantages over nails and self-tapping screws.

- The process of clapboarding surfaces is characterized by lightness and simplicity. Even an untrained master will be able to complete it if he calculates and marks everything correctly. You can also dismantle the lining without any problems.

- Cleamers are attached to the base, and not to the lining, so hardware cannot contribute to the formation of damage, cracks and other defects on the surface of the board. This ensures a long service life, less chance of skin decay and loss of its beautiful appearance.

- Visual structural integrity. Visible elements of fasteners can spoil the uniform look of the interior design. Cleamers are installed imperceptibly, so the boards just fit snugly together, without forming gaps and drops.

- There is no need to purchase special accessories for installation. All work is done with a hammer or screwdriver.

- Cleamers provide reliability and durability of the structure, also because they are made of metal.

- Additional protection against deformation.

Like any other construction method, mounting decorative boards on clamps has some disadvantages. The most significant of these is the cost of the products. Quality staples can make a significant difference in the cost of your finishing. Although saving money, it is possible to reduce the operational properties of the sheathed layer, therefore this defect is completely covered by all the advantages of these metal products.

Views

When buying kleimers, it must be borne in mind that there are several standard sizes. The differences between them lie in their purpose - different types of lining differ in thickness.

The following varieties are most often found on sale:

- # 1 is used for vinyl lining and wall panels;

- No2 allows you to conveniently attach vinyl clapboard and MDF panels;

- # 3. This type of kleimer is suitable for fixing more dense Euro lining and chipboard panels;

- No. 4 is presented mainly for euro lining;

- No. 5 is a common fastener for decorative boards made of aspen and linden;

- # 6 is suitable for block house fixing.

Installation technology

First of all, you need to decide on the tool and the amount of consumables.

To carry out the work you will need:

- square;

- building level or plumb line;

- roulette;

- screwdriver or ordinary screwdriver;

- hammer.

In order to calculate how many clamps you need to buy, you need to know the approximate consumption of products per 1 square meter of finishing. Typically 20 clamps are used. They are packed in 100 or 200 pieces in one box.

Accordingly, if you want to sheathe a room with an area of 40 sq. m, the calculation will look like this: 20 × 40 = 800 products or 4 packs of two hundred pieces.

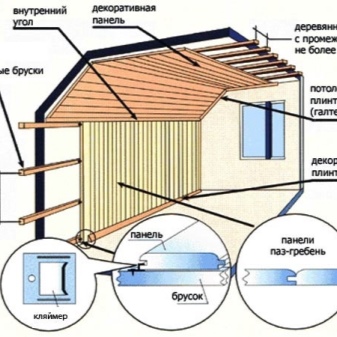

Installation of lathing

The lathing is a necessary element for decorating premises with lining. It solves two important problems that arise in the process of any repair.

- Levels the surface of the base to improve the appearance of the wall or ceiling. Walls, especially concrete or brick, are rarely 100% even. There are drops, curvature, various depressions and bulges. The use of the frame allows you to level the wall without additional time-consuming plaster, putty and other materials.

- The lining is attached to the frame beams. The connection turns out to be much more reliable and faster to make to a wooden surface than to other types of bases.

- In the process of installing the lining on the lathing, a space appears between the base and decorative boards, which allows airing and not allowing the effects of dampness and moisture to form - various microorganisms.

When arranging a frame mesh, it is necessary to pay attention to several points so that the repair will last for a long time.

- In order for the lining to be installed exactly throughout the entire perimeter of the room, it is necessary to constantly monitor the installation process using the building level. Otherwise, the curvature can become visible to the eye and spoil the whole impression of the finish.

- So that the boards are firmly and reliably fastened, do not bend, do not deform under the influence of the environment and over time, it is better to install battens at a distance of no more than 60 cm from each other.

- The frame is fixed on special metal profiles to the base of the walls. It is possible to use profiles for GKL sheets.

- Beforehand, it is imperative to treat the crate with antiseptic solutions for wood. This will help to avoid the formation of mold, rot and mildew on the surface of both the beams and the lining. Thus, the service life of the cladding can be significantly increased.

- The glue connection should be performed using two or three metal products. If you use only one nail or self-tapping screw, then the quality of the cladding will be in question. And with mechanical stress, there is a risk of individual boards falling out, as well as damage to neighboring elements.

Base marking

The markings should be applied depending on the direction in which the lining will be located. Directionality can be both decorative and practical. For example, in saunas and steam rooms, it is recommended to give preference to the vertical sheathing method so that moisture deposited in the seams between the boards does not accumulate and has the ability to drain freely downward.

Vertical installation involves the installation of clasp joints at a distance from the wall, which is equal to the size of the board and its width.

The horizontal markings should ensure that the bracket is positioned close enough to the floor to allow access for the hammer to attach the cleaimer. To increase the decorative effect of the finish, diagonal laying is also used, or several methods of installing the lining are combined to obtain unusual patterns on the walls or ceilings. These methods are typical for living quarters. In this case, the work is difficult to do without experience and training. The lathing is usually installed perpendicular to the direction of the boards.

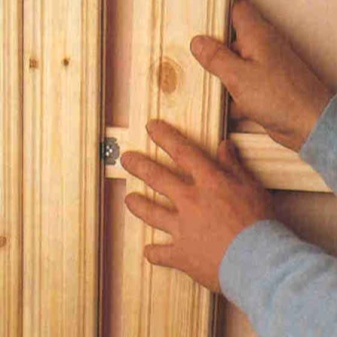

Installation of lining

For a horizontal arrangement, it is necessary to press the end of the board against the wall. Try to do it close and always with a comb. Then you can fix the clamps with metal products.

If a vertical installation is chosen, then the clamp brackets must first be fastened, then insert the groove of the board onto the hooks. After that, the boards will be inserted one after the other into the grooves with the ridges, and the clamps will provide fixation.

And in fact, and in another case, it is necessary to fit the boards in size to each other in order to avoid gaps.

Useful Tips

Here are some guidelines to help you maximize the durability, durability and decorative properties of the coating.

- If the base does not contain significant deviations in curvature, it is still better to fasten the boards to the crate with clamps.

- If clapboard is used for cladding a wooden house, the walls should be pre-treated with antiseptic liquids, all defects and rot should be cleaned.

- When carrying out internal work, the purchased lining should be kept for at least a day inside the room in order to exclude expansion or contraction of the already mounted surface when the humidity and temperature change.

- It is recommended that in the case of horizontal laying of boards, start mounting from the upper edge of the room so that the first element does not spoil the appearance. If the last board adjacent to the floor needs to be trimmed, then all defects and gaps can be hidden with a floor plinth in color.

- The lining made of plastic allows work at a temperature of at least + 10 ° C to ensure the integrity of the products.

- Work with wooden planks should also be carried out at freezing temperatures to minimize shrinkage.

- To prevent moisture penetration through the gaps between the boards on the base, you can additionally install the layer with a moisture-protective film. Liquid sealant and various adhesives cannot be used.

- It is necessary to carefully choose the material from which the kleimers are made, especially for the decoration of facades and street structures. The metal must be stainless so that corrosion does not spoil the structure of the tree.

- If it is necessary to install sockets or cables, first completely sheathe the surface with clapboard, and then, using a special saw, make a hole in the required area.

Finishing

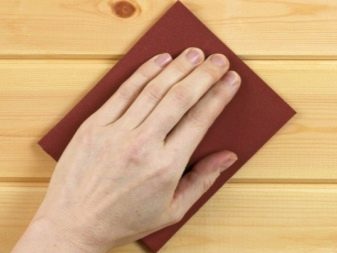

In order for the surfaces to retain their original appearance and beautiful natural shine for a long time, the lining can be additionally processed.

- It is necessary to clean the boards from the accumulated construction dust. If there are visible stains, you can use wood bleach or wood stain.

- Irregularities and grease stains can be sanded off.

- A primer will become necessary for subsequent processing. Outside, you need to walk with a polystyrene compound; inside, acrylic-based liquids are suitable.

- An antiseptic will not be superfluous, especially in a damp room and for outdoor use.

- To give a beautiful shine and shade, you can walk over the surface with varnish. Internal work is carried out using alkyd or acrylic paintwork materials; for external finishing, polyurethane compounds are useful, which more reliably resist environmental factors.

For information on how to choose the right clamps for lining, see the next video.

The comment was sent successfully.