Mineral wool insulation: how to choose and use it correctly?

When building any private house, it is important to make sure that it is as habitable as possible, which, in turn, puts forward certain heat standards that should be in the room all year round. If you do not insulate walls and other surfaces, if necessary, then building materials will wear out faster, and any temperature drops will be very noticeable inside the house.

To avoid negative consequences, it is important to choose an easy-to-use, safe and reliable insulation, which is mineral wool specimens.

Peculiarities

In the process of repairing or building a house, in addition to issues related to the calculations of the foundation, the choice of bricks, the layout of the future floor plan, it is important to ensure that the rooms are comfortable in all manifestations. Correct location towards the light, optimal dimensions of the room, and a comfortable temperature inside each room.

This can be achieved only by insulating the walls, and, if necessary, also the ceiling, if the attic is used as a living space.

There are quite a few options for materials that can now be used to make the walls warm, and not everyone knows what is better to choose and in what case. It is believed that mineral wool insulation is the most suitable option for use inside the house, because it is not afraid of fire, which protects the walls from possible fire, even in the case of inaccurate handling of the flame.

The most common material that is most often worked with is mineral wool. This is not some specific option from the set, but a group of heaters, which are united by a composition that contains: natural gabbro-basalt rock, waste glass, metals, silicate and clay bricks.

Insulation has the form of the finest fibers, which can be arranged in a chaotic manner or have a clear direction. Thanks to this airy structure, mineral wool has excellent heat retention rates. The process of obtaining components for mineral wool is complex, additional substances are often used, these can be:

- formaldehyde and urea resin;

- phenolic alcohol;

- a combination of formaldehyde with phenol;

- bentonite clay;

- latex, bitumen and polymer emulsions.

To decorate the inside of the house, it is best to use mineral wool, which contains basalt, which is bonded with bentonite clay.

It is these components that are considered the safest due to the environmental friendliness of the product.

Advantages and disadvantages

In order to know exactly what material should be chosen as insulation, it is worth understanding its positive and negative sides. Thermal insulation with mineral wool has such advantages as:

- low thermal conductivity, which makes it possible to single out this material as one of the most successful for the insulation procedure;

- low fire hazard due to the non-combustibility of the cotton wool composition;

- the stability of the state of mineral wool with a temperature difference, the plate has the same appearance, without undergoing any changes;

- resistance to moisture absorption from the process of vapor movement between the insulation and the wall, this makes it possible to protect the walls from dampness;

- the composition of the insulation is resistant to chemical and physical factors;

- good vapor permeability, which allows the slabs to breathe;

- good sound insulation performance, which are achieved by the elastic structure of the canvas and have an acoustic effect, which gives full protection from external noise;

- ease of installation work;

- long term of use, which can be at least 25 and maximum 55 years under optimal conditions of use.

Based on the foregoing, we can conclude that mineral wool is an excellent material for warming a room. However, this versatile insulation also has its drawbacks.

- Additional treatment of the product with a water-repellent preparation so that the fibers do not absorb unnecessary moisture. If this is not done, wet materials will not do their job as well, and thermal insulation will be much worse.

- Large weight of the material, which is essential if you order the delivery of such materials by transport companies.

- The presence of a small amount of phenol-formaldehyde resin, which is harmful to humans. The content of this substance is very small and can not cause harm, but there is always the possibility of special sensitivity to it, which can expose health to an unreasonable risk.

- Danger of getting fiberglass fibers into the respiratory tract and on the mucous membrane of the eye, which forces the use of protective equipment during installation work.

When purchasing mineral wool, you should pay attention to the manufacturer, because the quality of the product often depends on it. Proven and large firms make more reliable, environmentally friendly and high-quality cotton wool than small suppliers, especially those that sell the product much cheaper than its market value.

To make the house absolutely safe and protect yourself and your family members from the effects of phenol-formaldehyde, which is released from the cotton wool when heated, you just need to choose a more expensive type of insulation, which is thinner and contains basalt instead of phenol.

Types and characteristics

Mineral wool is a type of material that can be used to insulate walls and other surfaces in a room. There are three main options.

Glass wool

It looks like pressed plates, the thickness of the fibers in them can be 15 microns, and the length is 5 cm. The material for the manufacture of glass wool is remelted glass, limestone, dolomite, borax and soda. The result of mixing all the components is a rather elastic and durable product. Has a strong hygroscopicity and density indicators, which are significantly lower than that of any other type of mineral insulation.

The place of use of this heat insulator is technical premises that will not be used for living. This is due to the fragility of fibers, which, when deformed, can irritate human skin, and are especially dangerous if they enter the respiratory system. In this regard, the installation of this material is carried out only with the use of protective equipment for the eyes, nose and mouth, as well as in overalls and gloves.

Another successful use of glass wool is in piping. Each mineral insulation has its own characteristics, for this type of thermal conductivity is from 0.3 to 0.05 W / (m * K). The temperature range is from -60 degrees to +450 degrees, and the vapor permeability index is from 0 to 0.6 mg / mh * Pa. Glass wool does not tolerate contact with water, as a result of which its thermal insulation performance is greatly reduced.

Slag wool

It is produced using blast-furnace slag obtained as metallurgical waste. The thickness of the fibers in this case is from 4 to 12 microns, and the length is 16 mm. Slag dust and small balls can be added to the base material. The place of use of slag wool is non-residential premises or those in which a person will not be for long. Due to its high hygroscopicity, low density and poor resistance to fire, it makes it impossible to use it for facade decoration, pipeline insulation, attic in places where the chimney will pass.

Due to the residual acids in the composition, it is impossible to allow the material to come into contact with metal surfaces. The main characteristics of this mineral insulation have thermal conductivity values from 0.46 to 0.48 W / (m * K), the range of permissible temperatures is from -50 degrees to +250 degrees, the moisture index per day is 1.9%. Outwardly, slag wool is similar to plain dark gray cotton wool. Such insulation is the cheapest of all three options, which is its main advantage.

Stone wool

This material is also called basalt wool, it is made through the process of melting volcanic rock (basalt, diabase, porphyrite), after which it is processed in a centrifuge, where the plastic mass takes the form of thin fibers. The next step is the addition of binders and a water repellent agent, which help to make the insulation resistant to moisture. The resulting mass is pressed and processed at a high temperature, which gives high-quality insulation at the output. Due to its low thermal conductivity, good vapor permeability and resistance to moisture, stone wool is the most suitable option for finishing the facade of a residential building.

Plates can withstand sudden changes in air temperatures without deforming.

If we consider the characteristics of the material, then the thermal conductivity will be 0.032-0.048 W / (m * K), the vapor permeability will be 0.3 mg / (mg / mh * Pa), and the maximum temperature that stone wool can withstand will be 1000 degrees.

This type of insulation is the safest for work and the very insulation of living quarters., because the composition does not contain formaldehyde resin, and the binder is bentonite clay, which can be used for the food industry. Environmental friendliness of the material, ease of use, safety of installation make this type the most popular among the rest.

As for other indicators, the size of mineral wool will have the following characteristics:

- thickness range from 30 to 100 mm;

- length from 1170 to 1250 mm;

- width from 565 to 600 mm.

If we talk about non-standard parameters, then the manufacturer Knauf creates mineral wool with a thickness of 50 to 150 mm, where the length and width are also different. The thickness of stone wool is from 5 to 10 cm, the length is usually 2 m, and the width is 1 m, but each manufacturer has its own characteristics of the size of the insulation. As for the slag wool, the fibers have a thickness of 5 to 15 μm and a length of 15 to 50 mm.

Selection Tips

Thermal insulation wool must be of high quality so that it can safely insulate the house from the outside. To find the most suitable option, you should pay attention to the various manufacturers of this material. The best is the German quality Ursa, Isover, Rockwool. When choosing a suitable option, you should pay attention to the relationship between the price and density of mineral wool.

The high density of the material requires additional raw materials, which means it is more expensive.

If you want to buy cheaper options for glass wool and slag wool, then you should not rush, because these materials have low sound insulation, in addition, they cannot retain heat as well as mineral wool. Installation is also more difficult, because working with glass wool is very dangerous, especially in inept hands.

Choosing the highest quality material for wall insulation, it is worth giving preference to mineral wool, but this material also has its own characteristics.

- It is important to find out in which direction the fibers are located: in an upright position, the product will better store heat and isolate from excess noise.With a dynamic arrangement of fibers, cotton wool acquires more durable characteristics and is able to withstand heavy loads.

- It is worth paying attention to whether there is a GOST badge on the packaging, which also says a lot about the manufacturing technology of the product. If we are talking about mineral wool slabs, then they are declared in accordance with GOST 9573-96, and in the case of stitched mats it will be GOST 21880-94, as for PPZh slabs, the value will be equal to GOST 22950-95.

When planning finishing with mineral wool indoors, you need to take care of the correct dimensions of the material. All indicators must exactly correspond to those indicated on the packaging, therefore it is better to measure everything personally, especially with regard to the thickness of the product, on which the quality of the entire repair will depend.

If finishing work is planned on top of the insulation, then you need to purchase additional materials that can be used for plastering, painting or wallpapering.

Insulation can be used not only for walls, but also for covering the ceiling and sometimes the floor. If a non-residential premises, such as an attic or basement, needs to be made suitable for a full or partial stay, then one cannot do without placing thermal insulation boards. The roof is insulated in the attic, and the roof is insulated in the basement, which helps to create optimal living conditions with minimal effort.

Subtleties of installation

Do-it-yourself thermal insulation at home is not an easy task, but if you have the necessary knowledge, the process becomes more understandable. Various materials can be used to insulate the facade of a residential building, but mineral wool has held the lead for many years. It can be used both inside and outside the home, and the result will be equally good.

It is believed that the use of foam on the outside of the walls is more productive, since it does not absorb moisture, unlike cotton wool., but it has a significant drawback, it is a fire hazard, which is especially important in the case of a country house. Due to their fibrous structure, mineral wool slabs allow walls to breathe, which foam does not, so the surface can begin to deteriorate over time.

If you install the mineral wool correctly, this will protect the material from the danger of getting wet. It is important to choose the right density of the product, it should be at least 140 kg / cubic meter. If you buy a thinner version, then after a while it will begin to sag, losing its qualities. Slabs usually have two thicknesses of 5 and 10 cm.

It is best to choose a thicker version, because it holds its shape better, does not deform or sag.

When choosing between a slab and a roll of cotton wool, it is better to give preference to the first type of product, since it does not need to be cut, which means that the insulation process will go faster and safer for the health of the employee himself. Considering options for mineral wool, of which there are quite a few today, it is best to opt for the basalt variety, for which the impact of water is least dangerous.

Having chosen the best insulation option for the facade of the house, it is important to know the correct sequence of work. They start with the preparation of the walls for installation, after which they go directly to the process of fixing the mineral wool slabs to the surface.

Preparation

In order for the mineral wool to adhere well to the wall surface and effectively perform its functions, it is important to properly prepare the wall surface for the installation process. This should not cause great difficulties, the technology practically does not differ from work in the case of foam insulation. To install, you will need the following tools and materials:

- scraper;

- spatula;

- plaster mortar;

- primers;

- pliers;

- sandpaper.

- The work on preparing the facade for insulation begins with cleaning the old plaster, it will interfere with the tight fit of the material to the surface, which will cause the development of fungus and mold, which will harm both the wall itself and the insulation. If the top layer is loose, then it will be possible to get rid of it with a spatula, all hardened pieces are knocked off with a hammer. This stage is important for high-quality surface insulation, preventing the possibility of condensate accumulation in cracks from old plaster.

- The next step will be cleaning the walls of the house from metal products of any kind: nails, staples, gutter and more. Such measures are necessary due to the corrosion of the metal from the effects of moisture, which in any case will accumulate under the insulation. Rust will eventually show through the mineral wool, and ugly stains will appear on the decorative finish.

- The next stage of preparation will be thorough cleaning of areas where there are oily stains, dust pollution, the presence of fungus, the growth of moss or lichen, which ultimately will have a detrimental effect on the insulation layer and the wall itself. If the facade of the house has been painted, then all paint must be removed, even if it adheres perfectly. Only after the wall is cleaned of all that is superfluous, you can start the putty process, which will help remove all wall defects, irregularities, chips and cracks in which water can accumulate and microorganisms develop. To prevent this from happening, it is necessary to additionally treat the walls with an antifungal primer.

- After all the work on cleaning the walls has been completed, all defects have been eliminated, and a finishing layer of primer has been applied, it remains only to wait until all materials are completely dry. Only then can you start installing mineral wool on the outside of the walls of the house.

Technology

Work on the installation of mineral wool requires not only knowledge, but also skill to work with it. TThe technology of insulation is different from working with foam, therefore it is necessary to carry out all activities responsibly. If you fix the mineral wool poorly and of poor quality, then it gradually destroys the plaster underneath, which leads to a partial or complete collapse of the insulation.

- The technology of fastening the slabs of cotton wool boils down to the fact that initially you need to make plumb lines, according to which it will be possible to exactly set the material. The simplest, but no less reliable way is to attach the nylon cord to nails. One nail is hammered in the upper part of the wall, the second in the lower one. The distance from one cord to the other should be 80 cm.

- Such a system also helps to make the formwork, correctly positioning the profiles. The cord is stretched at a short distance from the wall, which allows you to freely mount additional structures, if needed, while having a clear reference point. Having located the landmarks along the entire length of the wall, it is important to install a vapor barrier film before starting work with formwork and insulation. This measure allows you to protect the wall surface from excess moisture, while at the same time minimizing the amount of condensate that falls on the cotton wool, maintaining its integrity and extending its service life.

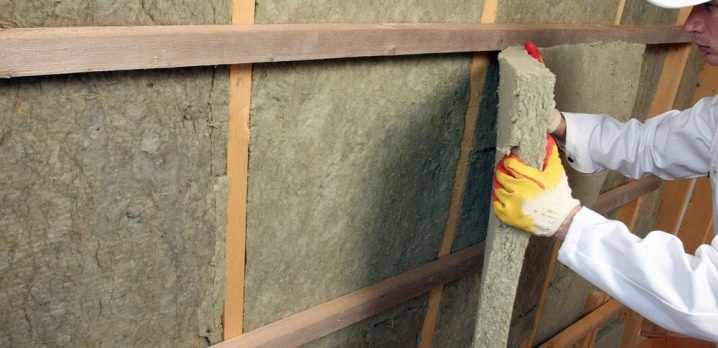

- Since mineral wool is quite heavy, it will not work just to fix it on the surface of the wall, like polystyrene, it will begin to recede over time. In this case, for high-quality insulation, it is worth using metal profiles in which the material is tightly packed. To ensure the best result, you should also use a special glue. Additional fastening of the insulation to the wall will be plastic dowels with large caps, it is they that allow ensuring the quality of work.

- The installation of the plates must be done correctly.so that each slab fits snugly against the next and has direct contact with the crate. Otherwise, cavities will form, which will affect the thermal conductivity functions, significantly reducing them.Having placed all the plates on the wall, you need to make a reinforcing layer by applying glue to the surface of the mineral wool, with which the material was processed during installation. Having glued it several times, you can get a durable reinforced layer that will protect the wool from the effects of wind and rain, which will save it from destruction by the forces of nature.

- The last stage, preceding the application of decorative finishing, will be the second layer of waterproofing foam, designed to additionally protect the insulation from the adverse effects of environmental conditions.

It is best to use lining or plastic panels as decorative finishing elements in the case of cotton wool, because they are capable of letting air through, which is extremely important when insulating a facade with mineral wool.

Helpful hints

- When purchasing mineral insulation, first of all it is worth reading the recommendations for use, which the manufacturer himself offers, because they are based on the knowledge of the raw materials taken for a particular material and the options for processing it until the finished look is given. If the work is carried out in inconvenient areas where you need to cut pieces of cotton wool or reduce its size, then this procedure is performed using a special knife.

- When purchasing mineral wool or starting to install it, you need to inspect the slab and evaluate the evenness of its edges, if they are frayed or torn, then it is worth replacing the product in the store or cutting it off if the problem was found already at home. There are areas where it is especially important to create maximum heat and sound insulation, for which cotton wool is placed not in one, but in two layers at once. Each tile should be superimposed on one another, and in the presence of a crate, its step should be such that the slab fits snugly inside, leaving no gaps.

- Since mineral wool tends to accumulate moisture, it is recommended to use it more often indoors... To make effective insulation outside, it is required to install a vapor barrier, on top of which the insulation will already be located. Such a measure will help protect the wall and the inside of the insulation from the negative phenomena associated with moisture. If we are talking about the effects of wind, rain and snow, then another layer of vapor barrier film can be used for protection, the effectiveness of which will be enhanced by a special adhesive solution that can be applied over the finished insulation.

- The use of mineral wool has been and will be popular for many years, since this material is harmless, environmentally friendly, can be used inside and outside the building, does not burn and has good sound insulation characteristics. The installation process has a number of its own characteristics, knowing that you can install the plates quickly and efficiently, ensuring comfortable living in the house for many years.

How to insulate a house with mineral wool insulation, see the video below.

The comment was sent successfully.