All about stone wool

When building a new house or renovating an apartment in a residential high-rise building, the issue of insulation arises. A special material designed to retain heat can significantly save on heating bills, especially in homes and cottages. High-quality insulation helps to ensure comfortable living conditions. However, choosing it is not so easy. And all many people prefer stone wool.

What it is?

Stone wool is an environmentally friendly heat insulator used for the arrangement of residential and industrial premises. The secret of the preservation of heat is hidden in the immobility of the air located in the fibers. And what is most interesting, these fibers are made of stone.

The presented insulation is made on the basis of basalt. And the production of basalt insulation has a lot in common with the natural production method. Scientists, studying volcanoes in Hawaii, found that when exposed to high temperatures, threads are formed that fold into a cotton-like shape. Accordingly, it is simply impossible not to use such a phenomenon.

The factories installed units that maintain temperatures up to 1500 degrees. And with such an impact, rocks melt like a piece of ice. Then the masters draw the molten mass into fibers and combine it with binding elements that give the cotton the required consistency and shape. In most cases, synthetic substances play the role of binders.

The prepared fibers are sent to the polymerization chamber, where the material hardens at a temperature of 200 degrees. Finished cotton wool is wound into rolls, cut into slabs or mats. And already at the end, the product is packed with foil.

A stone heat insulator can be called a versatile material that is recommended to be laid under siding, plaster and other types of cladding.

Basic properties

Despite the existing types of insulation, stone wool has undeniable advantages and several disadvantages. But first, you should start with the positive characteristics.

- Stone wool belongs to natural products, since natural resources are used in its production.

- This material can be used in different temperature conditions.

- Stone insulation has high-quality thermal conductivity.

The disadvantages include several parameters.

- Mice start in stone wool. Rodents, although they do not use the insulation for food, still spoil it.

- High price.

Having realized that stone wool is one of the best insulation options, you should get acquainted with its technical characteristics and properties.

Thanks to the capabilities of the modern world, it was possible to develop a technology for creating a waterproof product, covering it with a special substance.

Vapor permeability

Modern owners of houses and cottages are worried about environmental friendliness, safety of housing, comfort of the microclimate and are afraid of the appearance of mold. In this case, there are two opinions. The first proposition assumes that the house must be like a thermos. The second says that buildings must "breathe" due to the vapor permeability of the walls. Stone wool belongs to the second judgment, since it has the property of vapor permeability. Water molecules penetrate the heat insulator without condensing on the fibers, due to which the cotton wool does not get wet.It is recommended to use such insulation in wooden buildings so that the walls can "breathe."

Street air enters the room not only through the window, but also through invisible cracks and microcracks. If the walls are deaf, and the house is completely isolated from drafts, then after a while mold will appear on the walls and ceiling. That is why adherents of sustainability want to have "breathing" walls. And without a stone insulation that removes water vapor molecules, you can't do it.

Fire safety

As mentioned earlier, stone wool is produced on the basis of a non-combustible gabbro-basalt group. To melt the stone on an industrial scale, a temperature of 1500 degrees is required. This heat is comparable to the vent of a volcano. A domestic fire will never be able to reach such a temperature, therefore, the insulation, when exposed to even an open flame, will not deteriorate and ignite. Its fire resistance is 100% quality.

In addition to fire resistance, stone wool resists heat, reducing its strength, so that the structure of the house does not suffer. In simple terms, the building does not collapse, its individual elements do not melt.

In addition to the fact that stone wool can withstand combustion temperatures, it does not emit toxic substances that negatively affect human health.

Sound absorption

Stone insulation is distinguished by enhanced sound insulation, and all thanks to the complex structure of cotton wool with chaotically intertwining fibers with an air gap. This property was to the liking of the owners of the recording studios attached to the residential building. Speaker system working at full power does not interfere with the rest of the neighbors... The material reliably protects the owners from impact noise.

Durability

Like any other insulation, the installed stone wool undergoes a shrinkage procedure. But this process is so insignificant, which means that it does not in any way affect the service life of the material. Plates or rolled rolls do not lose their production shape, and drafts do not appear between them. Today, during the production of stone wool, the material is treated with a water repellent agent, which creates a water-repellent effect. This feature allows you to keep the structure of the insulation in dampness and rain.

Environmental friendliness

Stone wool belongs to the list of sustainable materials. Some manufacturers are even willing to provide the corresponding Eco Material Green certificate. And yet, the issue of environmental friendliness of stone insulation should be understood in more detail.

In the recent past, studies were carried out that revealed that basalt wool is an unsafe product. In 1995, in the booklets of several companies it was indicated that the fibers of basalt insulation are combined using synthetic resins obtained by the interaction of phenol and formic aldehyde. Resin in its characteristics has a lot of differences from natural fibers. And first of all, this is the difference in temperature treatment. Once in the oven, the fibers do not melt until the temperature inside does not exceed 1000 degrees. The resin, in turn, begins to decompose at 200 degrees, giving off a pungent odor.

Other manufacturers specified that the amount of phenol-formaldehyde binders in the composition of the stone heaters they produced was negligible. This means that they cannot harm human health. However, in 1997, a classification of insulating materials was published, which indicated that mineral wool contains hazardous alkaline earth metals, no one could refute this theory. Today, many manufacturers make stone insulation based on the presented binder. And it belongs to the 2nd hazard class of volatile compounds.

Surely many people know that formaldehyde contains highly toxic allergens. And in the composition of stone wool slabs, this substance is more than 6%.But if you look from the other side, formaldehyde is nearby throughout a person's life. It is present in furniture and even in outdoor air. So it is impossible to argue that stone wool is environmentally friendly, however, its composition has not done serious harm to anyone yet.

Comparison with other materials

Before you know the difference between stone wool and other heaters, you should dig deeper into the technical characteristics of the materials. Stone wool, like glass wool and slag wool, is a type of mineral wool. Accordingly, the question - which is better, mineral or stone wool, disappears by itself. The only difference is in the production technology and the raw materials used. Insulation, which contains broken glass and quartz sand, does not require the use of resinous substances. Accordingly, during installation, the material crumbles, and small particles can enter the respiratory tract of a person.

Clay and carbonate insulation, which is a waste of the metallurgical industry, cannot be used inside residential premises. This material is toxic and may cause allergies. Basalt insulation is made only from natural materials that are not harmful to human health. Further, it is proposed to familiarize yourself with the clear difference between stone and mineral insulation. Do not forget about such a type of insulation as penoplex.

This material is a product of synthetic origin, in which the difference between stone wool is already felt. Well, the cost of penoplex is much lower than that of any kind of mineral wool.

Varieties

According to the criteria of texture, shape, composition and fitness, stone wool is divided into several varieties.

- Soft. This material is made from fine fibers. They form many cavities, inside which air is retained, which is an obstacle to heat loss. Soft wool is used to insulate points that do not involve serious stress. In simple terms, it can be used as a cover for facades and roofs.

- Medium hardness. In this case, more rigid fibers are used in the manufacture of stone wool. This material can be used to insulate facades where there are strong air currents.

- Hard. This type of stone wool uses thick fibers. Such slabs are designed for heavy loads. Laying can be done under the screed and inside the walls.

Soft stone wool is sold in roll form, while medium to high hardness varieties are made in the form of slabs. Some builders claim that it is much more convenient to work with cotton wool in rolls. Others are sure that the slabs are more comfortable to install.

To date, another variety has been developed, namely, blown foil stone wool. The presence of foil provides a double insulation property. In simple terms, the foil variety leaves heat outside and reflects it, directing warm air into the room.

This type of insulation can have both one-sided and double-sided foiling, due to which it belongs to the list of universal heaters.

Marking

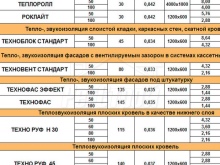

Do not forget that stone wool, like any other building material, has its own markings. The main difference between each individual brand is the density of the insulation. From here, the difference in properties is also seen.

- P-75. This brand of stone insulation is characterized by a minimum density and is designed to cover horizontal surfaces with low stress, for example, an attic.

- P-125. This marking is intended for insulation of interior walls, partitions and ceilings. But the main thing is that the air contained inside the material is quite enough to block extraneous noise and retain heat.

- P-175. Stone wool of this marking is characterized by increased density.It is used to insulate reinforced concrete floors. According to external data, P-175 cotton wool resembles a slab made of wood chips.

- P-200. This marking is characterized by maximum density and rigidity. A load of 200 kg is assumed for each cubic meter of material. But, unfortunately, this material has several drawbacks. Due to the maximum density, the noise insulation in the room becomes low, and the thermal conductivity leaves much to be desired.

Dimensions (edit)

Today, stone wool slabs are presented in the most acceptable sizes. The required dimensions are determined by the ratio of length and width, for example, 100x50 cm or 120x60 cm. The minimum thickness of the stone insulation is 10 mm. There are also options for 20, 30, 50, 100 and 150 mm. The choice of thickness depends on the free space in the walls and other ceilings that require insulation.

Applications

Stone wool is a modern insulation that is very popular in the construction of new houses or in the overhaul of apartments. It can be used in the arrangement of not only residential premises, but also for the insulation of outbuildings. Stone wool is the best insulating material for facades. Its thermal insulation properties ensure that heat loss is prevented during cold seasons and that it remains cool in hot weather. In addition to arranging a warm facade from the outside, stone wool can be used to insulate walls from the inside. Only on top you will have to apply a layer of plaster.

Stone wool is also used as floor insulation. It is laid out on the base of the floor covering, after which it is poured with a screed. It can also be used to insulate a balcony.

When insulating a roof or roof, whether flat or pitched, it is recommended to use stone wool in a combined form. But the partitions inside the rooms should be covered completely. Stone wool can be used to cover columns, reinforced concrete floors, stoves, air ducts and chimneys.

Remarkably, this material guarantees fire safety and has many universal properties. It also has a high level of noise isolation, which is why it is used in the arrangement of recording studios. In addition to home furnishings, stone insulation can be used in a bath. This material not only retains heat inside the room, but also becomes an obstacle to the emergence of microgreens.

Manufacturers

Today, many companies are engaged in the production of stone wool. But not all of them are ready to provide a certificate of conformity and guarantee the quality of the manufactured product. In order not to choose a bad material, it is suggested that you familiarize yourself with the rating of the best manufacturers of stone insulation.

- TechnoNIKOL. Due to the high quality of its products, this company has gained recognition in many countries around the world. The brand pays special attention to the creation of stone wool. This product goes on sale in series. For example, rocklight, teplorell or technoacoustic. Each individual series has its own advantages and the corresponding price.

- Isover. A French building materials manufacturer offering customers a range of manufactured stone wool products. The samples isover classic, isover kl-37 and isover kt-37 are very popular. And the price of a product depends entirely on the density of the material and the required quantity.

- Rockwool. A well-known brand engaged in the production of high quality building materials. The stone insulation of this company is distinguished by its strength, durability, and, most importantly, better heat preservation.

- Knauf. The represented brand with a worldwide reputation is engaged in the production and sale of building materials of various types and directions. The assortment of the company is filled with a wide variety of insulation materials, where stone wool is of great importance.This manufacturer has made a lot of efforts to enrich its assortment with different types of stone insulation. And this effort was appreciated by lovers of the warmth and comfort of living quarters.

Installation features

Having dealt with the features of stone wool, we suggest that you familiarize yourself with the method of its installation. And you should start with the technology of warming the outer part of the house. This work requires adherence to a clear sequence of actions. Insulation sheets laid from the outside must be protected from the effects of the wind. For these purposes, glass-magnesium flooring, chipboard or fiber plates are suitable.

- Initially, you should clean the work surface from fittings, nails and other protrusions that could damage the insulation wool. A metal cornice should be installed at the bottom of the wall. The same mount is screwed to the ceiling. First, the cotton wool will lie flat. Secondly, it is a serious protection against rodents.

- The facade of the building should be primed. This is necessary to increase the strength of the adhesion between the surfaces. Then glue is applied to the back of the cotton wool. Then it is pressed against the primed working surface from top to bottom. As additional fasteners, you can drive plastic dowels into the plates. When laying the slabs, it is necessary to ensure that they are tightly joined together.

- A windproof material is laid on top of the stone wool, and a primer is applied on top.

Further, it is proposed to familiarize yourself with the process of installing insulation inside the premises. In this case, a prerequisite is the presence of a metal crate. If suddenly wooden slats were used to create the lathing, they must be varnished. The distance between the walls and the stone wool should be no more than 2 cm. This is necessary to create an additional air gap. To leave the required distance from the wall to the surface of the insulation, the glue should be applied not in a continuous layer, but in blotches.

In the process of work, you will probably have to cut the insulation. To do this, use a sharp knife or hacksaw. It is pointless to use power tools for cutting. After installing the insulation, it is necessary to proceed with the arrangement of the vapor barrier. It is attached to the guides with double-sided tape. The last stage of work is finishing. The prepared insulated surface is sheathed with plasterboard, then putty, and then the finishing is done.

The comment was sent successfully.