Rockwool: Wired Mat Product Features

Today on the building materials market there is a huge selection of different thermal insulation that will help make your building, whatever its purpose, more energy efficient, as well as provide its fire protection. Among the assortment presented, Rockwool Wired Mat boards are very popular. What are they and what are the features of these products, let's figure it out.

About the manufacturer

Rockwool was founded in Denmark at the beginning of the 20th century. At first, this company was engaged in the extraction of limestone, coal and other minerals, but by 1937 it was retrained for the production of thermal insulation materials. And now Rockwool Wired Mat products are known all over the world, they meet the most stringent European standards. The factories of this brand are located in many countries, including Russia.

Peculiarities

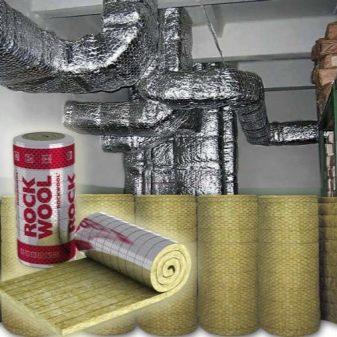

Heat insulator Rockwool Wired Mat is a mineral wool, which is not only quite often used in the construction of various buildings, but also used in the laying of water and heat pipelines. It is made from stone wool. It is a modern material based on basalt rocks.

Such cotton wool is produced by pressing the mineral with the use of special hydrophobic additives. The result is a material that has excellent fire-fighting properties and a long service life.

Advantages and disadvantages

Thermal insulation materials Rockwool Wired Mat have a number of advantages:

- these are environmentally friendly products that are absolutely safe even for small children;

- products are acceptable for use in kindergartens and schools;

- fully complies with state quality standards;

- a huge selection of products of this brand will help you choose exactly the material that you need;

- thermal insulation is not subject to decay, perfectly tolerates changes in humidity and temperatures, therefore, it has a rather long service life;

- all mats are rolled up, which greatly facilitates their transportation.

The disadvantages of this product include only a rather high cost, but it fully corresponds to the price-quality ratio.

Types and technical characteristics

For the production of various works, different types of insulation are used, therefore the Rockwool company offers a fairly wide selection of different types of thermal insulation. Here are some of the popular Wired Mat varieties:

- Wired Mat 50. This basalt wool has an aluminum protective layer on one side of the layer, supplemented by a galvanized reinforcing mesh with a cell pitch of 0.25 cm. It is used to insulate chimneys, heating mains, industrial equipment, and performs fire retardant functions. Possesses chemical resistance. The density of the material is 50 g / m3. Withstands high temperatures up to 570 degrees. Has a minimum water absorption of 1.0 kg / m2.

- Wired Mat 80. This type of thermal insulation, in contrast to the previous type, is additionally stitched with stainless wire throughout the entire thickness of the material, and can also be produced either lined with foil or without additional coating. It is used to insulate industrial equipment with high heating. Has a density of 80 g / m3. The operating temperature can reach 650 degrees.

- Wired Mat 105. This material differs from the previous type in density, which corresponds to 105 g / m3.Moreover, this insulation tolerates heating up to 680 degrees.

Also, Rockwool thermal insulation has an additional classification:

- If the name of the material contains a combination Alu1 - this means that stone wool, lined with unreinforced aluminum foil, is additionally covered with a stainless wire mesh. In this case, the fire hazard class is NG, which means that the material does not burn at all.

- Abbreviation SST means that stainless steel wire is used to reinforce the mat. Such materials also do not burn.

- Letters Alu indicate that the mat is covered with a galvanized wire mesh, lined with aluminum foil. At the same time, the flammability class is lower and corresponds to G1, that is, the temperature of the thermal gases in the chimney should not exceed 135 degrees.

- Combination Alu2 denotes the use of foil fabric in the production of thermal insulation, which excludes unwanted breaks in places of its maximum stress, such as bends, bends, tees. Such materials are also classified as completely non-combustible.

How to install?

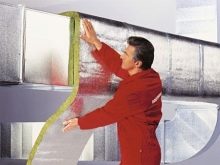

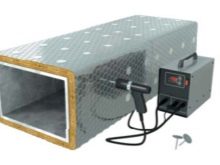

There are several ways to install Rockwool Wired Mat insulation. The simplest, but not the most aesthetic and reliable, is to tie the fabric with stainless wire. You can also use banding tape.

But this method is not always suitable, especially if the equipment has large enough volumes. In this case, special pins are used. They are welded by means of contact welding to the body of the object, then thermal insulation mats are installed, which, in turn, are attached to the welded pins using pressure washers. After that, the mats are sewn together with a knitting wire. Additionally, the joints can be glued with aluminum foil if necessary.

Reviews

Buyers speak of Rockwool Wired Mat insulation well enough. It has a large selection, various sizes, you can choose the material that suits any need. The material itself does not crumble, it provides excellent fire protection, which is especially important in wooden buildings.

Among the shortcomings, the sharpness of the material is noted, but this is characteristic of any heat insulator made of mineral wool, as well as a rather high price.

For more information on installing Rockwool Wired Mat insulation, see below.

The comment was sent successfully.