Insulation of the roof from the inside with mineral wool

Arrangement of a warm roof must be carried out in several stages, while it is important to find a high-quality insulation that will be reliable and will last long enough.

Often mineral wool is used for this, which has its own characteristics and advantages. Therefore, if you decide to engage in roof insulation, carefully choose the material, and also familiarize yourself with the installation technology in order to achieve a high-quality result.

Peculiarities

Before starting roof insulation, you must carefully select a material that meets high requirements and has excellent performance characteristics. The best choice in this case would be mineral wool, which has already become a classic in the construction industry. The main features of roof insulation include the need to dry the rafter system before installation. This is a serious technological process that requires professionalism and time.

The most rational scheme is considered, according to which the external thermal insulation of the slopes occurs after the rafter frame is assembled, and the roofing material is laid at the final stage. This is an effective option for arranging roof insulation. When it comes to internal work, it is necessary to complete all installation work, after which you can proceed with the installation of mineral wool.

It is worth noting that this process can be carried out independently if you follow the instructions that will be described below.

The choice of insulation

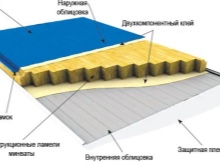

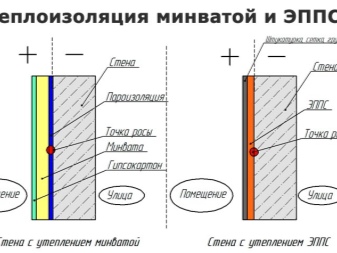

Today the market offers a wide range of materials that can be used as roof insulation from the inside. If these are ramps, a layer of thermal insulation is placed between the rafters in front of the topcoat, which is quite convenient. The question is which type of mineral wool to choose if there are several of them. For this it is important to familiarize yourself with their technical and operational characteristics, compare them, and analyze the benefits.

You can start by looking at glass wool, which has been in demand for many years. This material contains fiberglass, the thickness of which does not exceed 15 microns. These products are offered in several formats - rolls, mats and slabs. In terms of distinctive characteristics, glass wool has excellent thermal insulation performance, high resistance to fire and resistance to biological pathogens. If you choose a material in slabs, make sure how easy the installation will be. It's safe to say that this is a budget option for insulation, which attracts many consumers.

It should be understood that glass wool is not safe; to work with it, a protective suit and a mask are required, since the fibers can get into the respiratory tract and eyes.

Basalt or stone wool turned out to be next in the list of thermal insulation materials. It is a fibrous product that contains bentonite clay, carbonate and other composite ingredients. Such mineral wool is incapable of burning, it also has good thermal insulation performance, it is resistant to mold and mildew, which is an important advantage. As for the structure, it is not as strong, but the installation will be safe and easy, so the material attracts a lot of attention.

How to insulate different types of roofs?

Before proceeding with the insulation process, you need to learn about the different types of installation of thermal insulation, because they are somewhat different. Since we are talking about installing material from the inside of the roof, the best option would be to install mineral wool in the space that remains between the rafters. But this method is suitable only when the thickness of the thermal insulation does not exceed the width of the rafters, otherwise you will have to resort to combined installation, and this will take more time. The type of roof should be taken into account, and even then the installation should be carried out.

Flat

These types of roofs are often found in garages and warehouses where reinforced concrete slabs are used. It will be necessary to assemble the frame structure if a monolithic plate with reinforcement was used as a material. The first step is to make sure that there are no defects, if they are found, you will need to make repairs, seal the seams, treat them with a primer. This will ensure good adhesion of the thermal insulation cake to the surface.

Experts recommend using liquid waterproofing materials to treat the ceiling - often bituminous mastic.

If you have a concrete ceiling and have prepared it, the next step is to install a timber frame. The main structural element is bars with a section of 50x50 mm, you can choose a galvanized profile. If you are settling on lumber, it is recommended that you treat it thoroughly with an antiseptic to improve performance and protect it from moisture. It should be noted that craftsmen use a metal profile more., which will last much longer, but it all depends on the correct installation technology and compliance with the instructions.

For the result to meet expectations, start by drawing several parallel lines at a distance of about 50 cm. Suspensions are mounted to them, use iron dowels. It is important to consider what kind of facing material for the ceiling you choose. If the weight of the finish is large, the installation step should be smaller. First of all, two profiles are suspended at the edges, then all the rest are horizontal, they need to be fixed with small self-tapping screws. Be sure to follow the horizontal alignment and the first profiles. Next, you need to pull on strong threads to form the plane of your ceiling covering. The intermediate components of the crate are installed along them, after which it can be assumed that the frame structure is ready.

Now you need to reinforce the ceiling with insulating material. You can choose either rolls of mineral wool or mats. The insulation is placed under the frame so that it rests on it. As for the layer thickness, it all depends on the distance that remains between the surface and the crate. The main rule is not to leave a gap between the parts of the mineral wool, because this will allow the cold to pass through.

Lay the thermal insulation in such a way that all parts of the mineral wool fit snugly, the best choice would be to install in layers. Carry out the installation in a checkerboard pattern, and then you can not worry about drafts. The final stage of roof insulation with your own hands will be the laying of a waterproofing film, after which you can do the cladding.

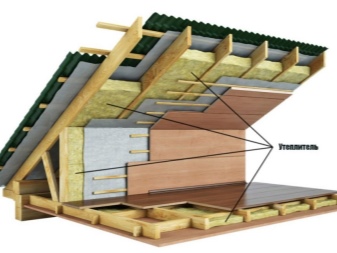

Pitched

Warming a shed roof of a private house or a bathhouse with mineral wool cannot be called a difficult process if you follow the recommendations. It is about laying thermal insulation between the rafter elements. It is also important to use a protective film here to prevent moisture ingress and keep warm. To insulate an attic or attic space, it is important to take into account that a crate is often installed on the rafter system, to which the roofing material is attached.

These are cold roofs, so it is important to insulate them to provide comfort and coziness in the house.

It is necessary to start laying the vapor barrier material from the bottom of the structure, gradually installing it in strips. Its main task is to prevent moisture penetration from the coating if leaks appear. And also it will provide protection from vapors.

The strips must be overlapped, covering the joints with adhesive tape.

After that, you can proceed with the installation of thermal insulation. Pay attention to the width, which should correspond to the rafters. If the mats or rolls are thin, the mineral wool can be folded in several layers, while it is also better to choose a checkerboard installation in order to avoid gaps and gaps. Use a stapler and steel staples to attach the waterproofing membrane. After that, you can start finishing with panel or board materials; plywood and chipboard are also often used. As you can see, the work is not difficult if you do everything in stages, as well as prepare all the necessary materials in advance. Roof insulation with mineral wool will provide you with a comfortable microclimate, and you will not have to think about repairs for many years.

Recommendations

Be that as it may, any work related to the construction and repair of the roof is a responsible process. It is imperative to follow the rules in order to get a quality result. You should not use mineral wool with a high density, it will be very heavy, which will put a heavy load on the rafter system. In addition, this characteristic affects the thermal conductivity of the material, and this is fraught with many problems. During installation, constantly check for any gaps. If a problem is found, it is enough to use a sealant to fix the defect. If the structure is made of lumber, it is necessary to process them with special compounds in order to extend the service life. It is imperative to provide a ventilation gap to allow moisture to escape from under the roof.

Insulation of the attic walls with mineral wool in the video below.

When we decided to insulate the attic, we didn't look for materials too much. Maybe lucky, but the tactics paid off. We bought a “professional” insulation, and they insulated everything with it - both the slopes and the floor. What I liked - there are 2 rolls of 0.61x4.1 meters in the package, and each of them is 2 pieces (50 mm thick). It is convenient to work - if on the floor, then rolled it out - and you're done. For the walls, you just need to cut off the desired length, then it rises into the frame along the standard step of a bar of 60 cm by itself, you just need to squeeze it a little. There is no need to fasten additionally! Unlike basalt mineral wool, it does not crumble at all and does not generate dust, there are no splinters either. They worked in ordinary cotton gloves and respirators. It will stand for 50 years - I don't know, but so far so good)

The comment was sent successfully.