Rockwool mineral wool: characteristics and application

Mineral wool is considered the most demanded insulation in the construction industry. There are many varieties of these products on the world market. Rockwool mineral wool occupies high positions in the popularity rating, the characteristics and use of which testify to the impeccable quality of the products, as well as its popularity among buyers.

What it is?

Mineral wool Rockwool is a heater made on the basis of natural basalt, due to which the mineral wool has excellent thermal and sound insulation properties. This is achieved by processing raw materials under the influence of high temperatures. This technology contributes to the formation of special fibers during processing, which are fixed to each other with a binder, forming separate mineral slabs. Such building material perfectly retains its original qualities and fully fulfills its direct functions.

Peculiarities

Rockwool mineral wool has its own technical features. Its standard dimensions are 1000x600x30, where 1000 mm is the height, 600 mm is the width, and 30 kg / m3 is the density. The thickness of the products can be 40-2000 mm.

Samples with a thickness of 50 mm and 100 mm are in special demand. They are actively used for thermal insulation of walls, roofs and pipes. The level of thermal conductivity of these products is quite low, and the installation process itself is very easy and fast. Even with long-term use, mineral wool fabrics do not lose their original properties, perfectly preserving the density of the structure.

The size and amount of material is determined based on the characteristics of the room, as well as individual needs.

Each Rockwool slab has a unique structure in the form of randomly spaced fibers. This feature allows the insulation to maintain the required rigidity without losing its resistance to tears. The interaction of fibers with each other, even when installed vertically, prevents products from folding under their own weight. The material is subject to careful treatment with special water-repellent oils, which significantly increases their hydrophobicity.

Such a unique production technology makes it possible to safely use these mineral slabs in the most humid rooms.

Advantages and disadvantages

Like any other building material, Rockwool mineral wool has its own advantages and disadvantages.

Let's start with the positive qualities of these products.

- Strength. The unique manufacturing technology makes it possible to produce the most durable products with an increased level of resistance to tears and mechanical damage.

- Environmental friendliness. The use of the most modern technologies and environmentally friendly materials make the insulation absolutely safe for health.

- Durability. The products are characterized by a long service life and perfectly retain their original qualities throughout the entire period of use.

- Water vapor permeability. A good level of vapor permeability protects the mineral wool structure from destruction and contributes to perfect thermal insulation.

- Fire safety. The material is resistant to fire, so that during a fire, the room is under reliable protection from destruction.

- Resistant to deformation. The improved structure of the insulation and the professional approach to production make the products as resistant to deformation as possible, which often occurs under the influence of unfavorable environmental factors.

- Affordable cost. All models of mineral wool are characterized by a reasonable price and excellent quality indicators.

Insulation Rockwool fully complies with all norms and quality standards, which is confirmed by the relevant certificates. Mineral wool from this manufacturer is completely non-combustible, therefore it perfectly withstands the highest possible temperatures, and in case of fire it does not emit smoke at all, which is a high priority. Excellent fire retardant function helps to preserve the integrity of any building structure, preventing its destruction.

Higher level water absorption and excellent sound insulation provide the most comfortable conditions for people to stay in the room. During operation, Rockwool products do not lose their original qualities, due to which they fully perform their functions for many years.

The disadvantage of Rockwool mineral wool is that this material is a favorable habitat for rodents. The structure of the insulation is fully consistent with this, so such a minus should definitely be taken into account in the selection process.

Views

Multifunctional stone wool Rockwool is presented on the world market in several varieties, each of which is characterized by an individual shape, parameters and purpose. The form of manufacturing basalt insulation can be of three types.

- Soft and roll mats. Designed for use as horizontal insulation in large areas with complex shapes.

- Plates. They come in standard sizes and are perfect for almost any surface.

- Cylinders. They are made in a cylindrical form and are intended for the design of pipelines of different diameters.

All Rockwool thermal insulation materials are classified in several categories of use.

- For building structures. Lightweight, water-repellent slabs, which are actively used in the construction of not only residential buildings, but also public buildings. They must be installed both from the inside and from the outside of the room. They are maximally resistant to shrinkage due to the increased elasticity of the structure.

- Particularly tough models. They are distinguished by a unique weave of the upper fibers, which contributes to the increased rigidity of the products. Able to withstand high loads without losing their original qualities. They are mainly used for thermal insulation of floors, for the formation of a reliable roof or for the installation of concrete structures.

- Special types. Their surface can be either ordinary or foil. They have an incomparable ability to absorb extraneous noise and vibration. They are often used as thermal insulation for fireplaces, stoves and chimneys.

A universal option is Rockwool "Tech Butts 50" mineral wool, which can fully perform the function of a heat insulator on air ducts, gas ducts, tanks, technical equipment and other devices.

Where is it used?

Rockwool mineral insulation has a wide range of applications. This material is actively used to insulate walls, ceilings, floors, roofs, partitions, facades, as well as structures for other purposes. This type of insulation is considered truly universal, since it has decent performance indicators, so it can be safely used in almost all directions.

The natural origin of products and absolute safety allows them to be used not only at home, but also in institutions where high environmental requirements are imposed. These include: hospitals, sanatoriums, schools, kindergartens and other special-purpose premises. In addition, many people prefer to use Rockwool mineral wool to insulate baths and saunas.

It is very important for these premises to have an increased level of sound and heat insulation in order to create the most comfortable conditions for rest. Mineral wool copes with this task perfectly.

Insulation Rockwool can rightfully be called a natural stone, as its composition is characterized by natural origin and incomparable strength. Each model has an individual purpose and differs in certain parameters. All this must be taken into account when decorating premises, as well as other structures and fixtures.

Mounting

Versatility and ease of installation are important advantages in the selection of insulating materials. According to customer reviews, Rockwool mineral wool is one of the best options for heat and sound insulation.

The laying process itself is quite simple, but at the same time it requires a certain literacy. In some cases, plate-shaped products do not even need to be fastened. As for large canvases, they are fixed with a special glue that is applied directly to the surface of the material. Mineral wool in the form of mats is attached to the surface with a metal mesh and dowels, and, if necessary, a crate is used.

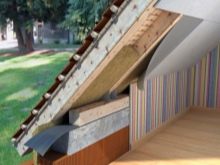

For the purpose of floor insulation, Rockwool stone wool is placed under a pre-made cement screed or between the joists. When installing the roof, the spaces between the rafters are filled with material, after which the joints are carefully processed with glue, ensuring excellent waterproofness.

Rockwool boards are stacked in a staggered manner with maximum density to each other. To create a high level of vapor barrier, foil or special film is laid under the mineral insulation.

It is important to note that the use of Rockwool functional basalt products as insulation is the first step towards creating the most comfortable and safe facility for staying. In addition, this material contributes to significant cost savings during the heating season.

Helpful hints

When buying Rockwool mineral wool, it is recommended to take into account its features and technical characteristics. Small particles should not fall from these products. Be sure to pay attention to the packaging, where the expiration date and storage temperature of the material should be indicated. But you also need to take into account the size of the insulation and the features of the facility where it will be used. During the installation process, it is advisable not to allow the location of the material too close to the electrical wiring.

When choosing, you should pay special attention to the density of the products. The level of resistance to loads directly depends on this indicator, as well as the degree of preservation of the original form during the compression process. Experts recommend using Rockwool insulation with the following density:

- for floors, ceilings and partitions 50-100 kg / m3;

- for facades 100-125 kg / m3;

- for horizontal surfaces within 35 kg / m3;

- under the screed about 200 kg / m3.

It must be remembered that the correctly selected density of the material is capable of providing maximum comfort and convenience during its operation.

For thermal insulation of public or industrial premises, it is recommended to use a special foil mineral wool Rockwool. It is a basalt insulation, which is covered with aluminum foil on one side to ensure heat reflection. Due to their increased strength, as well as excellent waterproofing properties, such products are actively used in water supply and air conditioning systems, as well as in cold chambers, baths and saunas. In addition, they are often used in residential premises to create reliable heat and sound insulation.

The manufacturer recommends at the time of purchase to pay close attention to the storage conditions of Rockwool mineral wool. After all, the quality of the material largely depends on compliance with the rules of storage and operation. The insulation should be stored on wooden pallets in a special package made of dense polyethylene without any damage. The room temperature must fully comply with the requirements and standards.

All these features are important for maintaining the original quality of mineral wool and its full functionality.

For the properties of Rockwool mineral wool, see the following video.

The comment was sent successfully.