Mineral wool: types and applications

For the insulation of the premises, special materials are used to protect the building from the effects of cold. Mineral wool is in great demand, which has a lot of positive qualities and advantages. This product is divided into several varieties, is available in different forms, so you should familiarize yourself with their features in order to choose the right material for further work.

Main characteristics

Any construction consists of different stages, and when it comes to residential premises, insulation is one of the important procedures. For this, mineral wool is most often used, the specific gravity of which depends on the density and various characteristics. The heat insulator can be purchased at any hardware store, besides, it is offered at low prices, but it also has a lot of other operational features.

Minvata provides not only heat, but also sound insulation, it must meet GOST standards, be fire-resistant, reliable and sufficiently dense.

As for the service life, it all depends on how well the material is laid.

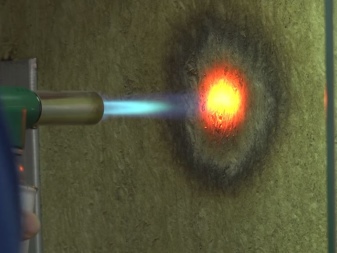

The main advantages of the product include a number of factors. So, as part of mineral wool no organic elements, therefore, the service life is so long that you do not have to worry about repairs for a long time. Many people are interested in the combustion temperature of the material, and here it should be noted that its flammability is minimal, mineral wool cannot ignite, and this is a significant plus. It is breathable insulation with a fibrous structure, due to which excess moisture is passed through and air circulates.

So the material will not mold and decompose, which also confirms a long service life. If you are worried about whether mice live in mineral wool, this is a misconception - rodents and insects are not attracted to this insulation, so it can be stored as long as you like. Temperature fluctuations are not terrible, as well as the influence of an aggressive environment.

Mineral wool has a low thermal conductivity: only 10 cm of insulation is equal to a bar of 25 cm, and brickwork with a thickness of 117 cm. It should be noted that the basalt type of this material is the most durable - it can be used for 50 years without worrying about performance. For slag, this period is somewhat shorter, but it can be purchased for warming a warehouse or utility room.

The material is often used for interior decoration according to SNiP. Due to its high vapor permeability, the mineral wool serves not only as a heater, but also protects against unnecessary noise, it can be used in wooden and stone structures.

Thus, the main factors for the choice of this material by consumers are its high quality, excellent performance and an affordable price.

Harmful to health

This is an important aspect to consider. The fragility of the fibers is a drawback of the heat insulator, and if installation is carried out without the use of protective equipment, including a respirator, goggles, gloves and a suit, mucous membranes can be damaged and skin irritated.The most dangerous types of mineral wool are slag and glass, with which many are familiar since childhood, because it could often be seen near residential buildings and basements. Today, many people decide to abandon the use of this type of insulation in order to protect their own health.

It should be noted that the composition contains formaldehyde substances, so it is better to use mineral wool for outdoor work. However, there is no need to worry if the normal temperature is observed - in this case, the material is not dangerous. During installation work, it is important to follow certain rules and technology: after installing the insulation, it is recommended to make a vapor barrier layer so that fiber particles do not penetrate into the room.

Types by composition

As mentioned above, mineral wool is divided into several varieties: some of them are more refractory, others are made on a synthetic binder, there is a foil material. Therefore, it is important to familiarize yourself with the features of each class in order to find the most suitable option.

Glass wool

For the production of this material, about 80% of cullet is used, the rest is made up of other ingredients, including sand, soda, limestone. The components are mixed, melted, and then centrifuged to produce fine fibers 5 cm long. The material has excellent performance. The only drawback is that it requires protective equipment to work with. Glass wool is in high demand for a number of reasons. First of all, it has high chemical resistance, it is suitable for laying on uneven surfaces, it absorbs sound well, copes with vibrations and has a low thermal conductivity.

The material is non-flammable and is offered at an affordable price. However, during installation, it is necessary to take care of vapor protection, it is necessary to take into account the causticity of the product and ensure good insulation. The service life of glass wool reaches 10 years, which also matters.

Before starting work with insulation, it is important to protect your eyes, respiratory tract, and also make sure that there are no exposed skin areas, as the fibers are brittle and particles can fly during installation.

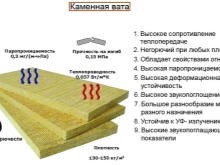

Stone

The main components of this material are diabase and gabbro. The thickness of the fibers can be from 5 to 12 microns, the length does not exceed 1.6 cm. As for the properties of the material, it is similar to slag wool, but there is no causticity, which is a big plus. The installation of the heat insulator can be carried out independently in a short time. This type of mineral wool poorly absorbs moisture, so this option is best suited for insulation.

Slag

Blast-furnace slags are used as the main ingredient for raw materials, from which fibers with a length of no more than 16 mm are obtained. In private construction, this material is most often used, moreover, it can be used to insulate non-residential premises. The advantages include the ability to install on curly and uneven surfaces, fire resistance, long service life, high-quality sound insulation and resistance to bio- and chemical substances.

However, it should be borne in mind that slag wool is not suitable for insulating water pipes or facades. During installation, it is necessary to use protective equipment - there are phenol-formaldehyde resins in the composition, therefore it is better not to use it for residential buildings. Most often, basements, non-residential buildings and attics, industrial facilities are insulated with slag.

The material has minimal rigidity, but good thermal insulation.

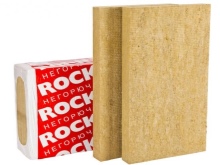

Basalt

Dolomite or basalt is the main component for making such a material. This is a fine-grained product with super-fine fibers up to 5 cm long. Since the composition contains a minimum set of ingredients, the production takes place using a simple technology. As for the thermal conductivity of basalt wool, it is the lowest compared to other varieties.

However, several advantages should be highlighted.The material has a high compressive stiffness, so during installation it is possible not to use supporting supports, it also copes with the influence of chemicals, and can last up to 50 years. Basalt has low hygroscopicity, is resilient and quite durable, is capable of absorbing sounds and does not burn. This type of mineral wool is environmentally friendly, therefore it attracts many consumers due to its versatility and excellent performance.

Combined

This type of insulation combines basalt mineral wool with foil. This material is excellent for protecting wood and steel structures from fire. Therefore, the product is actively used for water supply, sewerage and heating pipelines, as well as smoke channels, in saunas and baths.

Release form

On the market you can find mineral wool of all categories, which are offered in different forms depending on the scope of application. Manufacturers produce material in the form of mats, slabs and rolls, while the latter are in greatest demand. The roll option attracts with the fact that you can choose the length yourself, while others are offered in standard sizes. However, there is another type of such insulation, which is presented in the form of fibrous mass.

To use it, it is necessary to have special equipment, namely: a compressor.

Comparison with Styrofoam

Since mineral wool is a material for insulation, many people often have a question: is it better than polystyrene, and what are the differences between them. To do this, it is necessary to study the indicators of both products in order to compare the characteristics, and find the difference.

It should be noted that insulators are identical in almost everything. In this case, it is important to pay attention to the structure of the material in order to understand which of them is afraid of moisture or increased temperature. Since cotton wool resembles a fiberglass blanket, it is more suitable for soundproofing a room. But if you put it in water, it will absorb the liquid, become much heavier and lose some of its properties. Therefore, it is important here to protect the material from moisture, for which craftsmen use PVC film or a vapor barrier. This combination gives the maximum effect, and water will not violate the integrity of the insulation.

Foam, on the other hand, is a hydrophobic material that is not able to absorb water like a sponge, but moisture penetrates the structure, thereby destroying the connection between the balls. The slab will begin to crumble and crumble. Thus, the foam must also be protected from moisture, especially when it comes to outdoor use.

Comparing the characteristics, it should be noted that, unlike foam, mineral wool is resistant to fire, which presents it in a favorable light, and therefore many choose this particular material for thermal insulation.

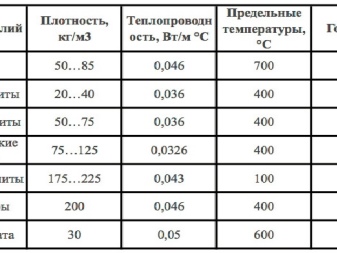

What density is there?

The density index is an important characteristic that is important to consider when choosing a material. There may be different options for mineral wool on the market, and you need to know how the density affects other properties and qualities of the insulator.

Soft has a density of 30-50 kg per cubic meter, is produced in rolls, therefore it is suitable for laying on a horizontal surface. The compressibility of the material reaches 50%, if the insulation is semi-rigid, it is used in technical rooms.

A product of medium hardness - 125 kg per cubic meter - has a compressibility of up to 12%. As for the denser mineral wool, it shrinks by 2%, the density indicator is from 150 to 175 kg / m3. If roof insulation is required, this option is most suitable. In the form of slabs, a material with a density of 200 kg per cubic meter is produced.

How is it produced?

The production of mineral wool requires professional equipment and a wealth of experience. The main materials of manufacture are various rocks.Carbonate and gabbro-basalt rocks, which are obtained during the production of rolled metal products, act as by-products. 90% of the mineral wool consists of rock, the rest is various additives. To make the insulation more dense, to bind the fibers together, manufacturers add astringents - these can be resins with phenol or bentonite clay.

The top layer of the material consists of thin craft paper, which has an aluminum or polyethylene composition. The components are mixed and then melted in a special device that produces mineral wool. The material is then cut into slabs, mats, or rolled into large rolls.

Application

Mineral wool has a number of positive properties, so it is actively used in the construction field:

-

insulation of a wooden and log house from the inside;

-

insulation of interfloor ceilings with beams, ceilings;

-

insulation of ventilated curtain facades;

-

mineral wool insulation of the floor system, road communications;

-

an interlayer between sandwich panels to provide more rigidity to the material, including concrete and reinforced concrete structures;

-

finishing of plasterboard partitions;

-

insulation of the roof, gas pipeline.

Of course, this is not the whole list of areas in which mineral wool is actively used, but these are the most common areas where it is impossible to do without such a product. It is safe to say that the product is the leader in thermal insulation materials.

How to choose?

If you decide to do home insulation, you need to know a few rules in order to choose the right material. For this, it is important to take into account the characteristics of the structure where the work will be carried out: is it residential or commercial, what material was used during construction.

Experts recommend calculate in advance the density of mineral wool, which will correspond to the task... It is worth noting that errors often occur not due to poor quality of the material, which happens quite rarely, but precisely with improper operation. Therefore, before buying, it is better to study all the technical characteristics and features of the use of a particular category of mineral wool.

Slabs with a high density are in great demand - they have minimal moisture absorption rates, so this option is best suited for facades. To insulate a room, you can pay attention to mats - this is a roll material, the design of which is quite convenient.

It is important to take into account the material from which the walls are made: if they are wooden, the density should not be high, because the surface must breathe, otherwise it will become moldy. There is an unspoken rule that for thin walls it is necessary to take a thick layer of thermal insulation.

How to fix it?

This is an important question that should be dealt with if you decide to do the insulation of the room yourself. Above all, make sure you have a protective suit for work and gloves to prevent allergic reactions and the ingestion of fiber particles in the respiratory tract and on exposed skin.

There are several options for installing mineral wool, depending on the scope and type of material.

It is important to consider what the walls of the facade are made of - foam block, drywall, wood, brick and more.

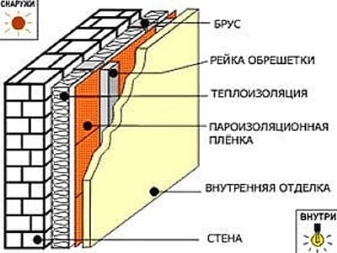

If we are talking about insulating the walls inside, then it is worth using a crate. Such a frame is made of bars that are attached to the wall. Between them there are cells where it is necessary to lay the thermal insulation plate. This method is also suitable for working with drywall partitions. But if you want to tiled exterior walls, this option is not entirely suitable. For fasteners, use foam glue or compound together with dowels. The outer frame is faced with soft slabs using stone wool.The frame is needed in order to lighten the load on the lower areas where the insulation is located. Here you can use either a wooden beam or a metal profile, which is more durable.

Thus, for fastening insulation, you can use the following options - glue or foam, dowels and crate. It all depends on your preferences and working conditions, while each method has its own characteristics and advantages.

You should start with the battens, which are often used for ventilated facades. Soft insulation is not suitable for wet walls, it does not have enough stiffness, so it will not be able to support the weight of the cladding. If you like the lamb or bark beetle finish, then you should consider other options. The lathing is most suitable for interior work, where it fully justifies itself.

To get the maximum effect, for a start, a vapor barrier material is laid on the wall, which can be fixed with a stapler. Then the basement profile is mounted, the timber is screwed on with self-tapping screws, only after that you can start laying the mineral wool. Make sure the slabs are tight enough so that there are no passages through which cold can pass.

This finish is great for wooden houses.

When it comes to glue fixing, this is one of those methods that is only suitable for ventilated facades. If you need to carry out plastering work, then you will need dowels-umbrellas, they are also called "fungi" - this method of installing mineral wool is 90% of cases, so you can safely consider it.

For everything to go smoothly, it is necessary to mark the places where holes will be made where the dowel is inserted. Make sure the cap is firmly against the material. The rod must be inserted manually into the sleeve, and then hammered into it with a hammer. The hat should be recessed, but don't overdo it.

Now you know everything you need to know about mineral wool, its technical properties, features of different types of material, as well as areas of application. Such information will help you to carefully understand what kind of insulation is suitable in your case, and how to work with it correctly in order to make high-quality sound and heat insulation.

Watch the video about mineral wool.

The comment was sent successfully.