Grout for paving stones and paving slabs

When deciding how to fill up the seams in the paving stones and paving slabs, the owners of summer cottages and backyards most often choose a grout that allows them to do the job quickly and accurately. It is not at all necessary to use ready-made building mixtures. It is worth talking in more detail about how you can seal the seams with modified sand or cement-sand composition, what proportion of ingredients to choose.

The need for grouting

A beautiful tiled surface on the paths, in the courtyard of the house or on the blind area always gives the landscape design a special appeal. Today, paving materials are on sale in a wide range, you can easily choose those that are suitable in color or shape.

But in pursuit of beautiful shapes or design of paving slabs, owners often forget about the need to properly seal the joints between the elements. For paving stones, this oversight can be a serious problem. Without high-quality grouting, materials are destroyed, efflorescence appears on the surface of the tile, and the appearance changes.

Laying of pavement coverings can be carried out on different bases (based on the expected loads). In this case, even the most tight junction of the elements to each other does not provide complete tightness. The tiled carpet has gaps that need to be filled.

The refusal to use grout makes the coating vulnerable to various external threats.

- Moisture. Water falling out with precipitation, formed when snow and ice melt, begins to destroy the tiles. When freezing, it becomes hard, expands, displaces the paving stones, leading to its destruction, the formation of cracks.

- Roots and stems of plants. If the base was not concreted or ordinary soil, sand was used to fill the joints, plants will be sown over time at the joints. Their roots are capable of piercing even asphalt, and for tiles they are enemies number 1 at all.

- Rotting organic matter. It gets into the seams by the transfer from the soles of the shoes, it is carried by the wind. Insects start up in the seams, the decay processes also have a certain chemical activity.

To avoid such sources of danger, it is sufficient to grout in time and then renew it periodically.

What can be used to fill the seams?

When choosing how to fill the seams in paving slabs, you should carefully consider the selection of ingredients. You should definitely not use quarry sand containing a large amount of clay impurities. Mixtures based on it are of low quality and crack quickly. There are many other formulations that can be applied immediately after styling or over time.

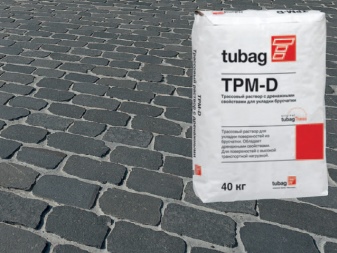

- Modified sand. This type of aggregate can be simply poured into the crevices. Modified filling sand contains additional polymer additives that harden after contact with water. Unlike cementitious aggregates, it does not leave marks on the surface of the coating. The modified sand easily penetrates the seams and allows air to pass through.

- Tile adhesive. Unlike compositions on a cement-sand base, it has elastic polymer binders. For paving with a drainage base, choose moisture permeable mixes (such as PFL from Quick Mix or Rod Stone). If the finished grout is waterproof, you need to take compositions with trass and cement binders. These are produced by the same Quick Mix, Perel.

- Sealant. This type of material can be called an improved solution for reinforcing tile joints. It solves the problem of weed growth, improves the properties of the sand backfill. Acrylic sealant is applied to the surface of the filled joints, fixing them. It is completely transparent, absorbed into the sand, strengthening its surface layer.

- Cement-sand mixture. Dry compositions can be used to rub over classic concrete tiles. For ceramics, it is better to choose other options.

- Putty with primer. It is sold in the form of ready-made solutions that are mixed in a container with water. It is necessary to introduce the mixture into the seams with a construction syringe so that it protrudes above the surface to a height of about 1 mm. After drying after 24 hours, the seams can be rubbed. You can make a colored grout by adding a special pigment to the white base.

The most environmentally friendly and safe solution when working with tiles of different density in the yard or in the country is modified sand in combination with a sealant. If the aesthetics of the coating is of great importance, you can use a putty with a primer, which provides an opportunity to create interlayers to match the paving stones themselves.

What tools do you need?

When grouting joints in paving slabs, it is worthwhile to acquire the necessary set of materials and tools in advance. Among the useful devices are:

- thick rubber spatula;

- a trough for mixing the solution (if the area is large - a concrete mixer);

- shovel;

- soft brush;

- construction sieve for sand;

- rags, unnecessary old things;

- buckets or water hose.

Having prepared everything you need, you can get to work.

Embedding methods

You can make even seams for a street path or a tiled courtyard in the country in different ways. Usually, backfilling with a dry mixture is used, but you can cover up the gaps with mortars: tile glue, sealant. The instructions will help you to perform all the steps correctly. But here, too, there are some subtleties. For example, you cannot start work immediately after installation - you need to wait at least 72 hours if there is monolithic concrete below.

There are other important points as well. Work is carried out only on dry tiles, in clear weather. There should be no accumulated moisture, debris, earth between the seams.

Liquid solutions

They are used for laying tiles, natural stone paving stones. Granite and marble coatings are more demanding in the choice of compositions, and work must be done very carefully.

If classic Portland cement is used, take a mixture of the PC400 brand in a ratio of 1: 3 to sand. The solution is prepared so that it has the consistency of liquid sour cream.

The filling sequence will be as follows:

- the mixture is distributed along the seams in portions;

- it is leveled with a rubber spatula, a metal tool will not work - scratches may remain on the surface;

- having processed all surfaces, they are wiped with a rag, removing excess and drips of the mixture;

- curing takes 3-4 days.

If, after hardening, the solution shrinks strongly, you can repeat the procedure until the seams are completely closed.

Dry mixes

They are considered versatile for work on concrete, ceramics, and other fine-pored materials. The most popular mixes have a cement-sand base. It hardens easily after filling with water. You can prepare them yourself by mixing 1 part of PC400 grade cement and 5 portions of sand with a fraction size of no more than 0.3 mm.

All ingredients are combined, mixed without the use of water.

The order of grouting in this case will be as follows:

- the mixture is scattered over the surface of the tile;

- it is swept through with a brush, carefully rubbed into the cracks;

- the action is repeated over the entire surface of the coating - it is necessary that the gaps are filled to the very top;

- excess mixtures are removed from the coating;

- the entire surface is spilled with water from the hose - it is important to moisten the seam areas.

The coating will harden for about 72 hours.If, after hardening, the grout sags heavily, the action is repeated. Using a long-handled brush can greatly simplify the process of rubbing the mixture into the seams.

Modified sand

This is the name of dry mixtures, which, in addition to the quartz component, contain polymer additives that harden upon contact with water. The finished coating looks presentable, it does not wash out from the gaps between the tiles. Work is carried out exclusively on dry coating in the following order:

- sand in bags is delivered to the work site;

- the mixture is scattered over the surface, rubbed with a brush;

- the seams are abundantly spilled - there should be enough moisture;

- the remains of sand are swept away from the surface, the path or platform is rinsed from the hose, the formation of puddles must be avoided;

- the tile is wiped dry with a foam sponge;

- the surface is swept with a brush.

Polymerization in the seams occurs gradually - within 24-72 hours.

Recommendations

When preparing a tiled site for grouting, you should pay special attention to cleaning them from dirt. The easiest way to cope with the task is with the help of a compressor and a nozzle from an old vacuum cleaner. By blowing out the debris, you can further speed up the drying of the seams.

It is also necessary to prepare the cement-sand base correctly, otherwise the consistency will not be uniform.

First, 1/2 of the total volume of all sand is placed in the container, then cement is added. The remaining sand is poured at the end. In addition to mixing the ingredients more evenly, this approach will also reduce the level of dust in the air. Liquid, if provided by the recipe, is added at the very end.

Special additives help to improve the plasticity of solutions. Even an ordinary liquid detergent added in a certain proportion can act in this capacity. The solution can be slightly thickened, and its consumption can be reduced.

The comment was sent successfully.