Equipment for the production of fuel briquettes

Fuel briquettes are a special type of fuel that is gradually gaining popularity. Pellets are used for heating private buildings and industrial buildings. The products are attractive due to their affordable price and excellent performance characteristics. It is worth considering in more detail the features of the manufacture of briquettes and types of equipment.

Extruder Features

To begin with, it is worthwhile to figure out what Eurowoods are. This is an absolutely environmentally friendly type of fuel, the material for which is used:

- logging waste, which includes sawdust, small shavings, bark and foliage, also often use needles left over from woodworking;

- waste from enterprises that process agricultural products;

- straw, reed, small fractions of peat soils;

- bird droppings, which are formed in large quantities 1-2 times per season.

The advantages of the improved fuel include a low ash content, a long service life and a decrease in carbon dioxide emissions by about 10-15 times. The production of fuel briquettes is a modernized technological process, through which it is possible to glue particles together.

- First, the raw material is thoroughly cleaned, removing impurities. Also at this stage, preliminary crushing of wood waste into small particles is performed.

- Next, the material is dried. It is important to lower the moisture reading to 8-12% to get the desired result.

- The waste is crushed again in order to obtain even finer fractions, which will be easier to compress.

- The fourth stage involves the processing of raw materials with steam to increase the moisture index to certain values.

- Only after that they start pressing the material through the use of extruders - special installations.

- Then the finished briquettes are cooled and finished drying is carried out.

The last stage consists in packaging the resulting products.

Now more about the extruder. This is a machine by means of which it is possible to give it the required shape through softening or melting the material. The process is the extrusion of the compressed mass through the holes provided.

The main structural elements of the press are listed below.

- Mixer. Provides effective mixing of several types of raw materials and allows you to get a homogeneous mixture.

- Matrix. With its help, it is possible to give the raw material the required shape.

- Punch. It exerts pressure on the original mixture.

- A working mechanism equipped with a drive. It is necessary to convert electrical energy into mechanical energy, which is a compression force.

- Stanina. The base on which the rest of the structural elements stand.

The extruder also includes a housing, a heating element, a screw and a head for forming briquettes of a certain shape.

A press is a special apparatus with the help of which briquettes are produced compact and suitable for long-term storage and use.

Varieties of presses

Manufacturers produce different types of machines for the production of fuel briquettes. According to the principle of operation, the units are divided into two types.

- Intermittent briquette installations. In this case, the equipment repeats the same cycle: it loads raw materials, compresses and releases the finished product from the mold. The number of repetitions is not limited.

- Continuous action. Extruders belong to this category. The process of producing briquettes takes place through the addition of raw materials to the installation, followed by extrusion of the product. Also, the equipment is responsible for cutting the bars.

In turn, extruders are also divided into different groups.

Manual

These mini-presses represent a simple structure of steel elements, which includes:

- Press form;

- support part;

- piston;

- handle.

If necessary, such an extruder can be assembled by yourself. The advantages of the equipment include light weight and ease of transportation. The unit is more suitable for working with small volumes.

Hydraulic

They are distinguished by the presence of a piston pump, through the operation of which it is possible to adjust the performance of the installation. The design also includes an electric motor and a tank containing hydraulic oil. Features of the machines:

- discontinuous method of producing briquettes;

- creating an effort for pressing coal or other raw materials by pumping oil into a special cavity;

- high specific pressure - up to 1500 kg / cm2.

To obtain briquettes, the raw material is loaded into the press in pre-calculated portions. After compression, the machine releases finished pellets. The key advantage of the hydraulic machine is its low cost. Manufacturers also note the possibility of making briquettes in the form of bricks, which greatly simplifies the transportation and storage of the material. Among the minuses, there is a small performance.

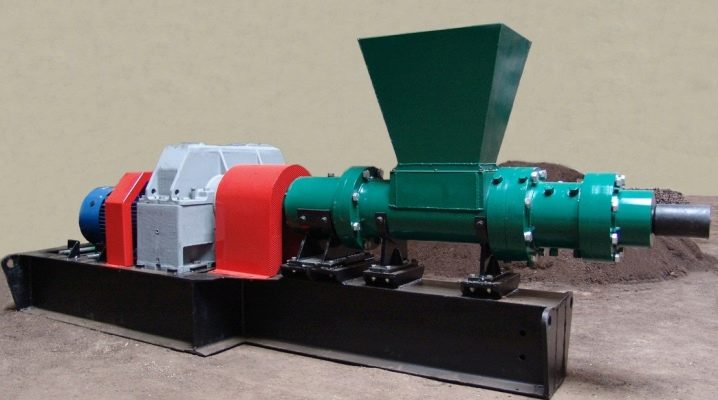

Shock-mechanical

Designed for the formation of briquettes according to the principle of impact extrusion. The design of the press includes a piston that is placed horizontally inside a pump in the form of a cylinder. The main parameters of such units:

- the method of making the material is continuous;

- working body - a crankshaft equipped with a connecting rod;

- maximum pressure - 2500 kg / cm2.

The equipment belongs to the category of installations of the middle segment in terms of cost. At the same time, the machine demonstrates excellent performance, is capable of working with large volumes of raw materials.

A separate category is screw extruders, through which it is possible to organize a continuous flow of briquettes production. A rotating auger acts as a working body in the machine, and the maximum pressure indicator reaches 3000 kg / cm2.

The press is based on the extrusion principle:

- the auger compresses the mixture;

- components are extruded into a special hole - a die;

- the conical shape of the channel provides the necessary compression of the raw material, forming a briquette.

A similar action is realized in the process of driving a wedge into the slot. The pluses of screw machines include:

- production of high-density briquettes, which allows to achieve long burning and greater heat transfer of the material;

- increased productivity, thanks to which it is possible to obtain more briquettes per unit of time than on a hydraulic device;

- a reliable log shape - a 6-sided cross-section with a through hole in the center, which provides air flow to the inner layers.

The material released by the screw extruder burns completely and leaves almost no ash behind.

The only disadvantage of the installation is the high price.

The market for equipment for the production of Euro fuel wood is represented by a wide range of extruders. Therefore, it is not always easy to decide which model will be more optimal for a reliable and fast process. When buying a press, you should consider the following points.

- Engine power. It directly depends on the throughput lever capacity of the circuit breaker, which is located at the entrance to the house, and is also determined by the cross-section of the cables. The best option is auger units: they have the maximum performance indicator.

- Dimensions. Small installations are suitable for home use, you can give preference to a hand-held extruder.

- The volume of raw materials produced. If a continuous production of briquettes is planned, preference should be given to large units with a high performance rate. For home use, manual installations are suitable, suitable for the formation of a small number of blanks.

Buying a machine for Eurowood requires a careful approach. Additionally, it is worth considering the manufacturer and characteristics. Do not ignore the reviews of people who have already used the purchased equipment. Experts advise against paying attention to the price, as it is not the determining factor.

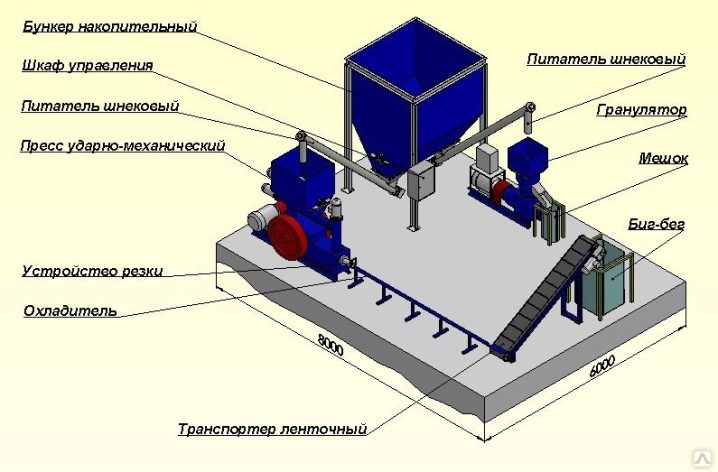

Other equipment on the line

Fuel briquettes are made from various types of wood waste, as well as from residues of biological origin.

The hottest products are obtained using oil and cereals.

A complete production line, in addition to extruders, includes a number of additional installations, each of which is responsible for a specific stage.

The following devices are also used for the production of high-quality eurodrops.

- Crushers and shredders. Mostly applicable when it comes to the formation of briquettes from straw, wood waste. Installations of this type are aimed at thorough crushing of raw materials. The finer the particles are, the denser the briquette will be, which means that its performance will also be higher.

- Calibrators. With their help, particles of the required size are sifted out, which then go on to the manufacture of briquettes. The rest of the raw materials that have not passed the selection are sent for additional processing.

- Drying chambers. Everything is simple here: the raw material is filled with moisture, and after crushing it is necessary to take care of reducing the moisture content of the wood. This is the only way to improve the work of the briquette. It should be noted that drying chambers are used both before and after grinding the raw materials. The drier the briquette is, the better its properties will be. Most of the settings allow you to adjust the parameters.

- Briquetting machine. In other words, an extruder, which is divided into several types. Depending on the type of equipment used, not only the final shape of the briquette differs, but also its characteristics. Modern models increase the temperature in the chamber, thus carrying out heat treatment of raw materials in order to form a protective shell.

- Packing installation. It is included in the work at the last stage. Eurowood is placed in cellophane to prevent moisture in the finished products and thus extend their shelf life.

Any machine can be improved if necessary. This will require a hydraulic jack or a special press that also works hydraulically.

In addition, to achieve the desired result, it is worthwhile to provide for the purchase of fastening materials and other elements of the future structure. Before purchasing the necessary goods, it is recommended to study the diagram of the future machine, which can be easily found on the network. Let's list the main stages of modernization.

- As a base, channels are used, which are welded together. Racks will be corners 100x100.

- The forming die is usually made of thick-walled steel pipe. The diameter is determined based on the size of the products that are planned to be manufactured. Additionally, holes with a diameter of 4–5 mm are provided in the pipe in order to organize the timely withdrawal of water during compression.

- A removable bottom is attached to the matrix, which will be used later to remove the finished briquettes.

- The stock is formed from a tube with a diameter of 30 mm, which is additionally equipped with a punch. The other end of the pipe is mounted in a hydraulic mechanism.

Stir the mixture thoroughly in the matrix before loading the equipment.A home-made drum, which is made of sheet steel, will help with this. You can also use an existing drum from the washing machine.

Finally, the last stage is the assembly of the tray with subsequent installation. Of course, such equipment will not allow obtaining the maximum density of Eurowood. But the installation will quickly cope with the task.

The comment was sent successfully.