Varieties and tips for the selection of drills for metal

Construction is a complex and complex process that includes the implementation of many diverse activities. One of the necessary stages in the construction process, due to which the necessary holes of various depths and diameters are obtained, is drilling. Even the most reliable and durable surfaces can be drilled. However, in order for this procedure to be as effective as possible, it is necessary to use the right tools. When drilling metal, it is especially important to choose the right drill bits. In the article, we will talk in more detail about the existing types of similar products, and also figure out how to choose the right one.

Peculiarities

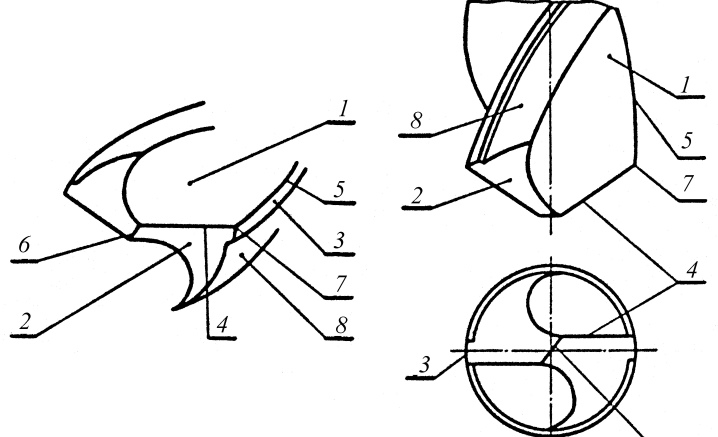

Drills for metal are essential and widely used tools that are actively used both in construction and in the field of mechanical engineering. If we talk about the appearance of the drill, it should be noted that it is a metal cylindrical rod.

It has sharp edges and spiral grooves to remove unwanted metal chips.

Consider the most important components of a metal drill.

Shank

This part is necessary to secure the drill in the chuck of the device used for drilling, be it a drill or hammer drill. The shank ensures the immobility of the working element during its operation.

Work zone

Using the working area, the drill creates a cylindrical hole. The integral parts of the working area include the cutting part and the guide grooves. In terms of its diameter, the cutting element occupies half of the total diameter of the drill. In this case, the guide grooves are used to remove chips from the working surface, thereby not disturbing or interrupting the direct drilling procedure.

Morse taper

This cone is used for those drills that are fixed in the spindles and tailstock of machine tools.

Foot

Not all drills have feet.

Such a composite element is relevant only for those work parts that are equipped with a tapered shank.

In this case, drills with jaws are usually designed to knock the device out of the mountings.

Neck

Due to the presence of the neck, the maximum comfort of the entry and exit of the sander during the machining of spiral grooves is ensured. It should be borne in mind that the neck itself is not a working element. Due to this it is traditionally marked with symbols describing the distinctive characteristics of the drill itself.

Guide part

The guide piece is often referred to as a gauge piece. This element is in contact with the wall of the hole that the drill makes in the metal. The guiding zone contributes to the fact that the device goes exactly along the axis of the hole - thus the recess is as accurate as possible.

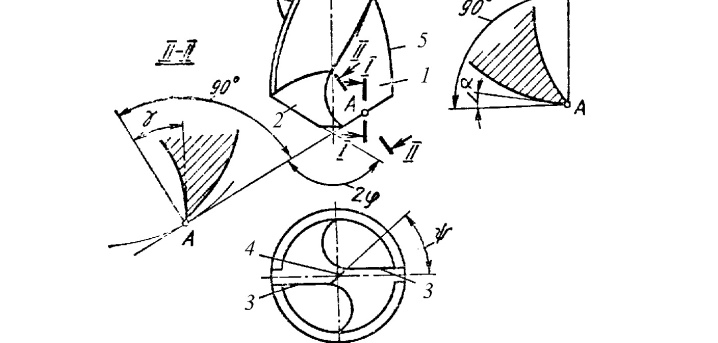

The angle of inclination of the spiral surface

Usually this figure is from 18 to 30 degrees.

Chip control groove

This part is necessary to ensure that the chips produced during drilling are rejected at the optimum speed and at the required level of inclination.

Insert diameter

The index of this element should be equal to the gap between the outer sides of sharp cutting inserts.

Cutting plate

The cutting insert is the edge that sits between the front and back surfaces.

According to its properties, it is quite sharp.

Main top corner

This angle greatly influences the actual drilling procedure and also determines how strong the drill itself is. For for drilling in metal to be as effective as possible, this angle should be 116-118 degrees.

Rear surface

The flank surface should be sharpened at an angle of 8-12 degrees in relation to the cutting part. This will significantly reduce the unwanted frictional force.

Jumper

This part is common to the 2 flanks of the drill, it has an important design function.

Transverse cutting edge

Essentially, the transverse cutting edge is a sharp edge.

This element is located on the jumper.

In the center of such an edge, the geometric center of the cutting part should be located.

Ribbon

A ribbon is 2 stripes that protrude above the spiral surfaces. These parts are essential for efficient and accurate bore calibration and also reduce frictional force.

Thus, A drill for metal is a working element that consists of a large number of the most important structural parts.

Production technology

Of particular interest is the procedure and technique for making the drilling elements. Before using this working tool, you need to understand how it is made. So, A drill for metal consists of various components, but only two of them are the most important and irreplaceable: the working part and the shank.

Traditionally, the functional part of the drill is made from strong and durable steel or carbide, while carbon tool metal is used to make the shank.

In this case, the very procedure for manufacturing drills for metal consists of several main stages.

Preparatory stage

At this stage, all the parts necessary for the production of a work item are prepared. So, workpieces for drills are cut by means of specially designed units. After that, the procedure for cleaning the blanks from various undesirable elements takes place.

Welding

After the completion of all preparatory processes, specialists in the manufacture of metal drills carry out resistance butt welding.

After the completion of welding, there is a mandatory removal of excess metal.

In this case, the blanks themselves must be given a clear cylindrical shape.

Turning

In order for the drills for metal to be of the required size as a result, it is imperative to perform a turning procedure. Along with turning, centering and trimming of the ends are also carried out. Thus, this stage in the production of a drill is very complex and complex.

Milling

Milling is carried out in relation to tapered shanks, spiral recesses and some other elements. Among other things, on At this stage, the drill workpiece is also heat treated and cleaned by means of a special installation.

Grinding

The grooves of the spirals, the shank, the working part are subjected to the process of grinding and polishing.

Drill sharpening

This procedure is the final one in the process of manufacturing drills for metal.

Species overview

Today there are a large number of varieties of drills for metal: there are high-speed, double-sided, universal, tubular, reverse, screw, stepping, combined and other types. However, they not only look different, but also have different purposes.

It is possible to distinguish them from each other, as well as to determine their main characteristics by means of marking and symbols.

For the convenience of users, several categorical classification groups of drills for metal have been adopted.

By form

Consider the types of drilling elements that exist today, which differ in shape.

Spiral

The most popular type of drills for metal can be called spiral. The process of creating a cylindrical hole in metal during the use of such a drill is primarily due to the movement of sharp cutting inserts.

Depending on the design category, twist drills can be integral or prefabricated (consist of disparate elements).

And also the parts can be equipped with a replaceable head.

Crowned

Another type of drill is crown parts. Crown (or ring) products are hollow working elements. This name of this variety is due to the fact that the cutting surfaces, which are an integral part of the drill, are arranged in an annular manner. Most often, this type of drill is used to create through holes and holes large in diameter.

Perovoy

Another type of metal drills are feather drills. Often, this kind of working parts is used to make holes in metal, which has been previously covered with a special casting crust and scale. The most important structural elements of feather products include straight depressions for removing shavings and the cutting part, which in its appearance resembles an ordinary plate.

This type is the most budgetary, therefore it enjoys a high level of demand among users.

but low cost leads to the presence of a large number of disadvantages: for example, poor quality and ineffective chip removal process. These drills are characterized by an increased level of rigidity.

Stepped

These workpieces are used to create shallow holes. In one pass, using tapered products, you can simultaneously create several cylindrical surfaces, in this regard, such parts are actively used in the implementation of various automated processes. If we talk about the design of such elements, then they are monolithic blocks (for example, they can be hex). Most often, step drills with turned parts are used in highly specialized areas.

Shank type

Shape is not the only decisive factor in the drill selection process.

Consideration should be given to the type of shank.

There are two main types of shanks: cylindrical and conical (Morse taper).

Cylindrical

Cylindrical shanks are designed for prefabricated metal drills. Today they are used for modular tools.

Conical

In the case when the drill is directly fixed in the spindle, products with a Morse taper are used.

Materials (edit)

Drills for metal are made from durable and reliable materials. These include:

- various types of steel and hard alloys;

- diamond and titanium compounds;

- tungsten and tungsten-molybdenum master alloys;

- cobalt;

- titanium;

- tantalum;

- sulfides;

- alloyed aluminum and others.

Dimensions (edit)

With regard to the sizes and diameters of drills for metal, there are strictly defined state standards in the form of tables. Depending on the specific type of work, you may need large, thin or even the smallest metal drill bits available today. Each size has its own unique designation. In general, modern metal drills range in size from 0.5 to 8 centimeters (for tapered shanks) and from 0.025 to 2 centimeters (for cylindrical shanks).

Marking

Marking and symbolic designation of metal products for drilling must comply with GOST. So, according to this document, the symbol must be applied to all parts with a diameter of more than 2 mm. At the same time, depending on the individual indicators of each individual drill, the marking may contain all or some of such information: diameter, steel grade, total size of the part, trademark, accuracy class and some other parameters.

Important. According to the above principle, metal drills are marked not only by domestic, but also by foreign manufacturers.

Popular brands

Manufacturers from Russia, Germany, Taiwan, Sweden, Japan and other countries of the world are engaged in the manufacture of metal drills for metal. The most popular companies and brands include:

- Volzhsky Tool Plant;

- Tomsk Tool Plant;

- PA "Tulamash";

- Zaporizhzhya Tool Plant;

- Bosch;

- Hasser;

- Ruko;

- Sandvik;

- Mitsubishi;

- Winstar;

- "Bison";

- Interskol;

- DeWalt;

- Hilti;

- Makita.

It is these brands that you should focus on when buying metal drills.

The products of these companies meet all quality requirements that are accepted at the domestic and international levels.

At the same time, you need to purchase goods only at official points of sale.

How to choose?

The choice of drills for metal is a rather important and responsible task, which should be approached with great care. Due to the wide distribution and wide variety of these working parts in the construction market, each user will be able to choose a drill for cast iron, for hardened iron, for aluminum, for hardened steel and for deep drilling, for a hammer drill or for a screwdriver. At the same time (regardless of the type of drill you need specifically for you), it is important to take into account several key characteristics.

Appointment

First you need to decide for what purpose you will use drilling products. So, some types can only be used for drilling a certain type of metal (for example, for aluminum or for cast iron).

Depending on the type of metal being drilled, the functional properties and characteristics of the drills will vary significantly.

In this regard, it is very important to study the catalog description of the purchased product.

Main unit compatibility

Before purchasing a drill, you need to make 100% sure that it will be compatible with the main device that you own (for example, a drill or screwdriver). It is especially important that both elements are comparable at the attachment point.

Manufacturer

Your preference in the process of choosing and purchasing products should be given to products of well-known international brands that are popular and respected among users. Such products, as a rule, comply with all existing domestic and international standards.

Price

Today, drills for metal are on sale from different price categories: both budget options and luxury parts. Wherein experts advise to choose such goods that fall into the middle price segment, as they correspond to the optimal ratio of price and quality... On the other hand, it is advisable to avoid the cheapest items.

Customer Reviews

Before purchasing this or that product, you should read the comments and user reviews about this product. You will find out whether the manufacturer's declared characteristics of the drill really correspond to the actual state of affairs (for example, whether the drill is durable in terms of its service life).

Place of purchase

It is recommended to purchase drills for metal only in specialized hardware stores. In such conditions you can always get the help of qualified and experienced sales consultants.

And also in official stores and dealerships you will find only high-quality branded goods, and not a cheap fake.

Given the above characteristics, you can choose products that will effectively perform their functional tasks, and will also serve you for a long time.

Storage tips

In order for the metal drills you have purchased to maintain their performance for a long period, you should take care of their proper storage. Let's consider the main tips and recommendations of experts.

Metal drills should be stored in specially designed containers: for example, tool cabinets or nightstands. In addition, it is advisable to pack them depending on the size, manufacturer and some other indicators. After use and before storing the drills, thoroughly clean the working parts from dirt and dust. Thus, you will prevent corrosion processes and prolong the use of the elements. If the drills are not used for a long period of time, then they should be periodically treated with lithol or technical vaseline.

Interaction of metal drills with aggressive chemicals is not allowed.

In the process of an intensive and long-term drilling process, it is recommended to treat the surface of the device with oil (traditionally, oil of the I-20 brand is chosen).

Only in that situation, if you follow all the above principles and recommendations, the drills will perform their functional purpose effectively and for a long time.

Which drills for metal are better, see below.

The comment was sent successfully.