Drills for confirmation: sizes and secrets of choice

Furniture drills for confirmation are a useful and convenient device that allows you to create a hole for a "turnkey" Euro screw, without additional countersinking. This type of metal fixtures is produced by Russian and foreign companies in a wide range of sizes. It is worth talking in more detail about how to choose a confirmation drill, what you need to pay attention to when working with it.

Peculiarities

Furniture drill for confirmation is a type of replaceable elements designed to create holes for Euro screws. The one-piece screed came into use in the 70s of the XX century, today it is used as a unified fastening by the largest manufacturers of household items. The confirmation drill is not uniform in its thickness, since the metal products that you have to work with have a thickened head and cap.

The need for a special tool for creating holes for furniture ties arose precisely because of the stepped change in diameters.

It will not work to do this with ordinary devices. Under the Euro screw for wood or chipboard, you need to drill a hole, in some areas of which the diameter will change. The design of the tool itself has a fastening part that is fixed in the drill chuck, and a blind hole for a removable part. It matches the screw and has a slip fit to avoid bending or breakage.

The cutting element for drills for confirmation is multistage, with a countersink that allows the head to be sunk in and change the width of the passage. There are also non-collapsible options. In addition, these drills have a number of characteristic features that distinguish them from other counterparts.

- Angled front side. This allows the drill to enter the material more easily and ensures correct centering when creating the hole.

- The angle of the screw groove, repeating the thread of the confirmation. It is needed to facilitate the entry of the fastener and better hold it in place.

- Adjustable stop position. It eliminates the need to additionally control the depth of entry.

- Thorough polishing of the nib. It facilitates chip evacuation, provides ease of sliding.

- The minimum dimensions of the thrust platform. This design eliminates creasing of the sidewalls of the hole. In this case, the strength of the drill does not suffer.

- The presence of a countersink in the drill design. The hole immediately has the desired stepping, you can screw the Euro screw without creating additional deepening.

For confirmatory drills, the characteristics that the metal itself has are also important.

Hardness values in the range 61-64 according to Rockwell, bending resistance, impact strength 150-165 kc are considered normal. Heat resistance should be at +120 degrees Celsius. A drill with such indicators allows you to quickly form holes in different types of surfaces, does not chip, and retains its characteristics for a long time.

Dimensions (edit)

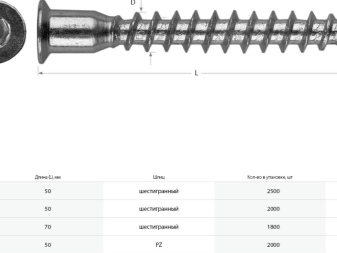

Depending on the diameter of the confirmation, the dimensions of the drills for such mountings also change. Overseas products must be labeled HSS for high-speed tool steel. Russian enterprises use metal with the designation P18, P9M5. The dimensional parameters of the drills for the confirmation are in millimeters, they can be as follows:

- 5×40;

- 5×50;

- 6,3×50;

- 7×40;

- 7×50;

- 7×60;

- 7×70.

When choosing the optimal diameter, it is important to take into account that the drill should not be smaller than the screw size. Otherwise, it will not go inside well, it can spoil the surface of the material. It is the accuracy of the choice that is important here. The diameter of the threaded part of the metal product is usually measured.

Popular manufacturers

Today, many well-known brands are engaged in the production of drills for confirmation. The first one-piece screed was introduced into its range Hafele company... It was she who designated the new products with the Confirmat label, giving it an unofficial name, almost more popular than the main one. The company still exists today, its drills for Euro screws are traditionally considered one of the best. Among other well-known foreign brands, stands out DeWalt from the USA as well as the Swiss brand Archimedes.

True, in comparison with the products of domestic companies, the price of their products turns out to be 2-3 times higher.

There are also leaders among Russian manufacturers. First of all, it is JSC "Metallist", "Izhevsk Furniture Accessories Plant FMS" (CJSC)... Good reviews for their products are received by LLC "BSI-instrument", LLC "Tula Instrumental Plant"... These enterprises do not disrupt production processes and pay sufficient attention to the heat treatment of steel billets. High-quality Russian drills for a single-element tie, even with repeated use, do not deform, retain their geometric parameters.

Among the inexpensive drills for confirmation, there are quite a few proposals made in China. The quality of such products is noticeably lower due to the fact that almost any alloys are used instead of special tool steel; it is often not possible to find out their exact composition. The exception is Haining Yicheng Hardware Co, Ltd.

How to choose?

When choosing drills for confirmation, it is very important to pay attention to a number of points.

- Drill type. It can be collapsible and one-piece. They have the same number of holes, but the ability to position the tool gives a great deal of variability when working with Euro screws of different diameters.

- Compliance with the size of the fasteners. It is imperative to choose drills, taking into account the diameter of the screw, otherwise, when screwing in, the metal product will simply jam. This problem becomes especially serious in those cases when work is carried out with solid hardwood. For MDF, chipboard, the mismatch of diameters can lead to swelling and cracking of the material.

- Steel type. Responsible manufacturers must indicate it on the product packaging, in the labeling. If the product is manufactured abroad, the mark must be HSS. The use of drills that are not made of tool steel will lead to a significant reduction in their service life and deteriorate the quality of work.

- Price and country of origin. Everything is simple here. If the budget allows, it is better to choose an instrument of American and German marks. Russian products are also quite suitable for their purpose, but you need to make sure that the correct steel was used in their manufacture. Chinese drills should be purchased only as a last resort - their cheapness does not pay off, moreover, you can spoil the furniture parts during assembly.

These are the main recommendations that should be taken into account when selecting drills for a confirmation.

It is important that the purchased tools meet the established quality standards, do not have pronounced nicks and roughness on their surface.

Usage Tips

To work on the assembly of household items - cabinets, shelves, shelves, 6.4 mm euro screws are used. They correspond to drills with a working diameter of 4.5-5 mm. This will make the hole wide enough, the fastening is reliable, and will exclude damage to the material. When working, it is important to make sure that a countersink has been made under the head of the euro screw, otherwise it will not enter the hole completely.

When working on creating holes for Euro screws, it is very important to follow a certain procedure.

- Make sure that the confirm drills match the screw sizes. Pay attention to whether the parameters of the smooth section of the Euro screw and the seating surface of the tool match each other. Do not use a drill with pronounced roughness.

- Make markings for fasteners on the surface of the parts to be fastened. It must be as accurate as possible, otherwise gaps or protrusions will appear when the parts are joined.

- Fix the surface of the material in the desired position.

- Install a drill with a drill strictly perpendicular.

- Place an unnecessary piece of chipboard or other material under the sheet or workpiece - with through drilling, this will avoid the formation of chips.

- Drill. In the end piece, the hole will be blind. In the main one - end-to-end.

It is important to know that accurate positioning of the tool is very important when drilling into the face of the workpiece.

Small thickness requires strict geometry when creating a hole, otherwise the Euro screw will pass obliquely and pierce the decorative surface of the material, spoiling its appearance. To get rid of chips during work, you need to pull out the drill several times.

When working with two parts at the same time, the amount of time spent is reduced. But for such manipulations, additional devices are required to fix the workpieces relative to each other in the correct position. Clamps and other types of clamps should be used. Parts are joined at the end, at a right angle.

All these recommendations will help not only to easily select suitable drills for the confirmation, but also to use them correctly in the process of work.

What is a drill for confirmation, see below.

The comment was sent successfully.