DIY folding tables

The desire to save money pushes enough people to try to make furniture with their own hands. Such an intention is commendable, but in order to achieve a good result, you need to take into account many subtleties and nuances, carefully think over everything. Think about shape and color, material and construction.

Shapes and sizes

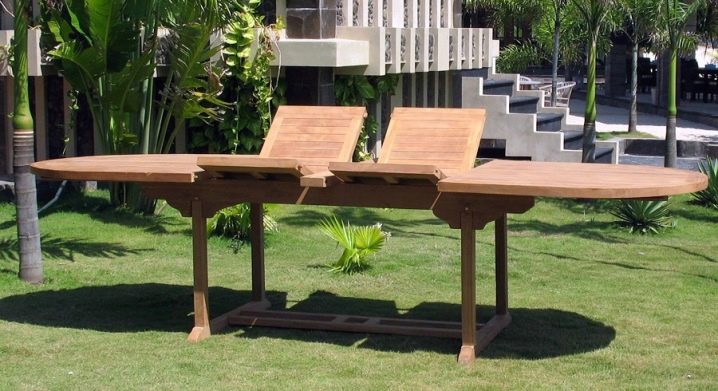

An oval table is considered convenient and practical, due to the absence of corners and blurred lines, the design looks very elegant. In fact, it combines the best features of round and rectangular variations to create a comfortable and welcoming environment. While saving space in the room, there will be enough space on the surface of the countertop for almost any purpose.

The semicircular shape is appropriate in a variety of styles, due to the decoration and design, it can be used both in the lush baroque and in the discreet high-tech. You will not be limited in the choice of materials. They are traditional and the most modern:

- A small square table is good for its classic expressiveness; it is often equipped with a transforming mechanism.

- A small folding table is appropriate for summer cottages (country houses), which are visited only in certain seasons, if necessary, it is not difficult to give them a lift and take them back.

- However, if you want, you can immediately make a large table in order to seat the whole family and guests in addition to it.

Consider purely practical considerations when sizing. For 1-3 people, there is simply no point in making large structures, but for those who like to assemble large companies, the situation is completely different.

note that furniture should not seem overly voluminous or lost in the middle of the room. Usually, 60 cm wide and 40 cm deep are allotted for each seated person, additionally reserving part of the countertop for a salad bowl, common dishes. Four adults will be very uncomfortable if the diameter of the circle is less than one meter, six people will need at least 1.3 m, and 8 - at least 1.5 m.

Materials (edit)

Wood worktops are a classic, win-win solution, characterized by a long service life, practical to use and very elegant. Its serious disadvantage is its high cost, as well as stylistic inappropriateness in small rooms. With a lack of space, it is better to make a folding table from chipboard with your own hands. This design is also ideal for kitchens because it easily tolerates humidity and is easy to clean.

A solid wood table is rarely found even where it is permissible for design reasons. After all, metal legs are preferable to oak, pine or birch due to their increased strength and stability. The profile tube is well suited for creating legs and racks, wheels can be installed below if there is a desire to make the table also mobile.

Plywood can also be used in the clamshell design. Polypropylene pipes can serve as an excellent substitute for metal and wood in the manufacture of individual parts of furniture. Although they are not very durable, they allow you to create decorative elements of an original look. Important: if you do not know how to do diffuse welding, plastic carving, you can use the gluing method. The material, unlike PVC, is not poisonous, it can be used even in children's rooms.

How to do it?

A different method is used for each type of folding table.

Transformer

When preparing a transforming table, you always need to choose the mechanisms of the transformers. They can be made with springs or using a gas lift, both solutions help to unfold and fold furniture as gently as possible. Inexperienced people should prefer spring option, it is simple and reliable to use, while the springs will not spoil the appearance of the structure.

The calculation of the product is quite simple, especially if you use computer programs. Choosing laminated chipboard, order cutting to professionals or make a detailed cutting card yourself. Never deviate from the manufacturer's recommended tabletop thickness. When the original material is received, fold all the blocks to check the accuracy of the intended dimensions.

When marking out dark chipboard, use stickers. Pencil and marker marks are completely invisible.

To assemble the table frame, use confirmations and a special drill. When the base is ready, insert the springs, then the mechanism. If it is heavy enough, parts often have to be connected through. Having correctly calculated all the nuances, you can not be afraid that the coffee table will turn out to be crooked, fragile, ugly.

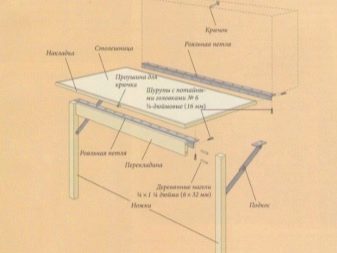

Bench table

It will not be difficult to make a wall table, like the option attached to the windowsill. The tabletop should not be thinner than 20 mm and thicker than 30 mm, then it will be both strong and not too heavy. Any width can be made, as long as it is in harmony with the desired height. As for the length, when calculating it, functional features, upcoming placement and ease of use are taken into account. The legs must be strong enough to support both the mass of the main structure and the exposed dishes and dishes. In especially difficult cases, the legs are fastened with mutual ties.

In order not to be mistaken with the place where the legs are screwed to the floor, you can do it simply - drill where you put it.

A folding table located above the radiator (battery) must have a certain number of holes, otherwise the heating of the room will deteriorate. Attention: when mounted above heating and heating devices, chipboard is not suitable at all. It is better to use natural solid wood, MDF board or plywood. It is necessary to use triangular supports only for short and medium tables; they are also unacceptable when located above batteries. Direct attachment to the wall will be much more appropriate. Do not forget to attach the workpiece to the attachment point in order to once again clarify all the parameters and eliminate errors.

Table-bed

This solution is in great demand, but it is necessary to prepare a space in the wall for displaying furniture - best of all, racks and cabinets. Think over what dimensions should be, be sure to draw up drawings in order to avoid mistakes. Making a sofa table means preparing a box, a bed and a lifting mechanism. The box is either a stand-alone design or is included in the product, depending on the intentions of the manufacturer. It is attached to the wall.

Attention: tables that transform into beds are best assembled made of chipboard, furniture shields are not suitable for them. The boxes are made of 5x5 cm bars, for the external strapping of the frames, they take supports with a height of 14 cm.The lateral decorating structures are made of an inch board with a layer of wood 1.2-1.5 cm, and a piece 4 cm deep is used to form the legs. It is not difficult to facilitate it, for this you only need to cut out the core of the supports.

To make the finished structure stronger, screw in the self-tapping screws that occupy the legs from top to bottom.

Piano hinges or bar loops are required to create bases that can be stowed away when the bed is folded; a slight slope of the lower and upper ends of the legs will help make the furniture more reliable. Professionals recommend do not make the mechanism yourself, but purchase a ready-made, with a pipe for a domestic gas pipeline at the base: it will be able to open and close several thousand times guaranteed. And at the same time, the sofa will surely be positioned as needed. The table is held together with the bed by auxiliary rods, which can be easily pulled out as needed.

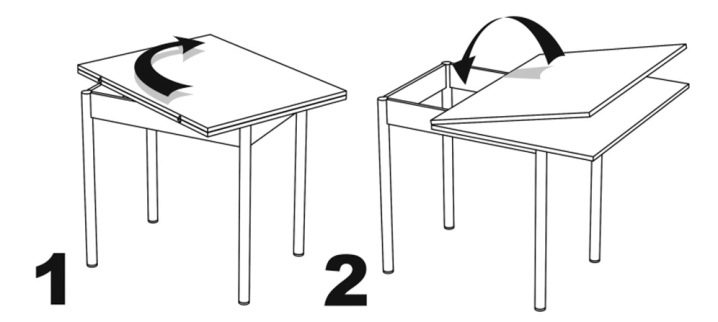

Swivel-folding

Making a swivel-folding table yourself is no more difficult than the options described above. Even special fasteners for rotation (for example, a swivel mechanism for mounting a TV), if the furniture will be used from time to time, can not be used. But you will definitely need laminated chipboard, the optimal layer thickness is 2.5 cm.The folding tabletop should be 77x50 cm.

A false tabletop is made with a size of 40x67 cm, legs and strapping for them are also prepared, corners and confirmations are taken. The tabletop is fastened with ombre loops, using from 4 to 6 wooden dowels. A false tabletop is placed on top, its corners are usually held by confirmations, although furniture corners can also be used. A mechanism is placed in the center of the turn, or a blind hole is drilled into which a steel dowel is half inserted.

Then it remains only to attach the lower part of the tabletop to the swivel system or make a hole in it for the remaining half of the dowel.

Optionally, you can use dowels to tie the false tabletop to the bottom of the turning part.

For information on how to make a turntable with your own hands, see the next video.

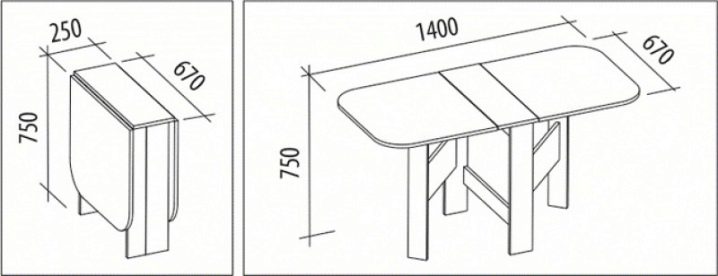

Book table

The advantages of this format are as follows:

- Minimum footprint;

- Ease of movement;

- The ability to easily convert the structure into a full-size table.

It only takes a few hours to create a product; the table top is formed by three parts. The center is always stable, and the sides can be lowered or raised. For the rest, it is allowed to diversify the table device at your discretion: you can use wheel legs, make solid or frame sidewalls. If you wish, it is not difficult to make the middle of the tabletop longer by placing a minibar or a cavity for folding chairs inside. There are also versions of book tables without a middle fragment at all, they are especially compact.

Novice craftsmen should make exactly the structure, not equipped with anything extra. It is easier to make rectangular wings at home, but if you can order them from a professional, rounded options are available. It is possible to manufacture all parts from chipboard. Another scheme involves the creation of legs and side struts from shaped steel rolled with lower wheels. According to professionals, it is necessary to abandon the piano hinges in favor of "butterflies" as they are more resistant to heavy loads. When the workpieces are cut, all parts should be covered with an edge. On the edges of the worktops, the flat edge can be replaced with edge profiles.

The table-suitcase outwardly resembles a real suitcase, inside which legs and a table top are wound. Such structures can be both very small and very large. In field conditions, aluminum products are optimal. The legs should be made of timber, folding inward thanks to the hinges; they should be made relatively massive and as stable as possible.

Bars, plywood or boards must be varnished to protect them from bad weather.

Shelving table

A children's wall-mounted folding table will give an excellent opportunity to do lessons, draw and sculpt, and other hobbies. When folded, it occupies exactly the same area as a regular shelf. For the manufacture of a table, a fibreboard with a thickness of 12 mm and a multiplex of 15 mm are useful. In the assembly process, flat dowels are used, it is desirable to have a flat-dowel milling machine and an eccentric sander. Fixation of individual parts of the structure is carried out using clamps.

Beautiful examples

Folding tables can look attractive in kitchens and living rooms, where they provide an opportunity to accommodate the whole family. For light interiors, metal structures, especially chrome ones, are perfect. We do not recommend even in the hall, not to mention the kitchen or any other dirtier room, to put pure white tables. Contrast between the table and chairs when it matches the color of the walls looks very nice and advantageous.

The comment was sent successfully.