Features of glass cutters and tips for choosing them

Glass cutter is a popular construction tool that is widely used in various fields of human activity. In our material, we will consider the features and types of glass cutters, and also figure out how to choose the right such tool.

What it is?

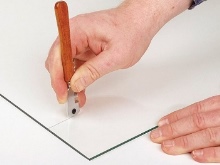

First of all, you should decide what a glass cutter is and what is its definition. A glass cutter is a hand-held glass cutting tool (as its name implies). Using a glass cutter, a scratch is applied to the surface of the material, and then the glass breaks with an application of force. A specialist who is engaged in cutting glass with this tool at a professional level is called a glazier.

Usually manual glass cutter used in the case when it is necessary to carry out simple work on a small scale. For industrial purposes, use specially designed tools with additional accessories. In addition, only ordinary glass can be cut with a standard manual glass cutter.

The hardened material will not be cut with this tool.

Description of species

Due to the fact that a manual glass cutter is a tool that finds a fairly wide application, and is also popular and in demand among users, there is a large number of varieties of similar inventory... For example, there are electric, circular, cutting, circular glass cutters, tools with a suction cup, with a ruler, with a compass, units for creating holes in a circle and many others.

Moreover, each of the types of glass cutters listed above looks different and consists of different parts. Let's give a detailed description of such tools and compare them with each other.

Roller

The traditional starting material for the manufacture of such glass cutters is Wolfram carbide (HSS can also be used in some cases). The design of the roller tool may include Pencil (straight) or Pistol (curved). Over time, the tool becomes dull, but sharpening it is impractical - it is better to buy a new tool later. On the market, roller glass cutters are sold at a price of 120 rubles.

Diamond

Diamond tools are used not only by amateurs, but also by professionals. This is due to the fact that glass cutter can process glass of any thickness. As you might guess from the name of the tool, it is made from technical diamond grit, and therefore the glass cutter does not require lubrication. As for the distinctive characteristics of the device, they include the fact that with its help the user can carry out extra thin cuts, accordingly, the result of your work will be as accurate as possible.

And also diamond glass cutters are shock-sensitive (This characteristic is due to the fact that the surfacing of the diamond tip on the steel holder is carried out by soldering with silver solders). If we talk about the appearance of the instrument, then it may have the shape of a pyramid or cone. At the same time, conical diamond glass cutters are much cheaper than pyramidal ones.And also there are several varieties of the unit, depending on the thickness of the glass on which it will act. The minimum cost of a diamond glass cutter is 250 rubles.

Oil

This type of tool provides for the supply of oil to the working area. Oil is needed to lubricate the cutting disc of the device. Oil glass cutters are made from high-speed steels... In addition, often the possibility of replacing the working head is provided (they can be conventional or designed for cutting thick glass). If we talk about the design of the device, then it should be noted the presence of a ball located above or below the roller. Such a ball is designed to evenly distribute the lubricant over the rolling surface of the roller. Accordingly, the cutting force is significantly reduced, and the service life of the glass cutter is also increased.

Mineral oils of medium viscosity (for example, I-20A) are usually used as a lubricant. The oil can be placed in a dedicated compartment using a conventional disposable syringe. The minimum price for such oil tools is 150 rubles.

Radial (or circular)

Radius glass cutters characterized by a high price... They are most often used on an industrial scale rather than at home. If we talk about the design of this tool, it should be noted that in appearance, such a glass cutter resembles a compass with a suction cup. And also in the design there is a metal ruler, which is equipped with a cutter.

The cutting element of the glass cutter is made of hard alloys.

Professional

In appearance, professional glass cutters resemble window scrapers. As for the constructive components of the tool, then Note the presence of a ruler, cutting element, oil barrel and guide bar. This unit is used only in a production environment. It should be noted the high level of comfort and ease of use of this type of glass cutters.

Besides, the device guarantees precise and deep cuts... However, in order to use the unit correctly, you need to have experience and relevant skills.

Thus, there is a wide variety of types of glass cutters on the market today. Each of them differs in its individual characteristics and qualities that must be taken into account in the selection and acquisition process.

The best models

There are many models of glass cutters on the market today. Consider the ranking of the best.

Stanley 0-14-040

This device is manufactured by an American manufacturer. It is great for home use. As for the design of the model, then it should be noted the presence of 6 strong and reliable rollers made of tungsten alloys... The glass cutter holder has nickel plating - due to this, corrosion processes do not develop. The handle is made of wood and has a lacquered finish.

To positive characteristics Stanley 0-14-040 include ease of use, a high level of reliability and an affordable price. On the other hand, this glass cutter is only suitable for cutting thin glass (4 mm).

FIT IT 16921

FIT IT 16921 is a Canadian device that is used for professional glass cutting. The head of this glass cutter is made of durable and reliable steel in terms of its characteristics, and is also equipped with a special screw, thanks to which the user can fix the desired and convenient position of the axis. The holder is made of plastic. In addition, for the convenience of users, the manufacturer has provided for the presence of special recesses for the fingers, as well as brass inserts - thanks to these elements, the tool will not slip out of the hands.

The model can cut glass, the thickness of which does not exceed 8 mm. TO advantages This model (in comparison with competitors) can be attributed to the fact that the design includes a transparent flask for oil, so that the user can see how much lubricant is left.

Among the disadvantages is the presence of only one video.

Brigadier Extrema

It should be immediately noted that the glass cutter Brigadier Extrema characterized by a rather high cost, accordingly, it is not available to all people. The model is the leader in sales of diamond devices in Russia. The head of this tool is made of hardened steel and the handle is wooden and varnished. The total length of the device is 18 cm. Even beginners will be able to use such a glass cutter; there are grooves on its body that are specially designed for neatly breaking glass of different sections.

It should be borne in mind that the Brigadier Extrema model requires careful storage in a specially designed case.

"Russia 87225"

As you might guess from the name, this glass cutter model is manufactured by domestic companies. Moreover, she for its price is quite budget, accordingly, it is available to a wide range of consumers. The device belongs to the category of diamond, respectively, has high strength. The head is made of steel and has a chrome finish and the handle is made of plastic.

Users note the fact that the glass cutter is not very convenient in the process of use, as it has a rather large weight - about 300 grams. Besides, glass with the help of the model "Russia 87225" can only be cut in a straight line.

Kraftool Silberschnitt 33677

Glass cutter model Kraftool Silberschnitt 33677 belongs to the oil category. In this case, the supply of lubricant is automatic. The cutting element of this tool is made of tungsten carbide, therefore, it is characterized by a high margin of safety. The head material is nickel-plated steel, and the handle is brass and has an abrasive surface. With this device, you can cut glass with a thickness of 1.2 cm.

Truper CV-5 12953

Truper CV-5 12953 - This is a Mexican-made roller glass cutter, it is one-piece and made of metal. In this regard, the device is characterized by the highest possible level of strength. With it, you can make cuts, the depth of which reaches 8 mm. In terms of usability, users complain that the handle is too thin.

Thus, today there are a large number of different models of glass cutters from different manufacturers (both domestic and foreign). Thanks to such a large assortment, each user will be able to choose for himself such a tool that will meet all his needs.

Which glass cutter to choose?

Choosing a glass cutter is not an easy task. In this regard, in the process of purchasing a tool, you should take into account the advice and recommendations of specialists.

- Appointment. First of all, you should decide for what purpose you will use the glass cutter, whether you are purchasing a device for bottles or pipes, for home or for a business, for inexperienced cutters or for professionals.

- Glass thickness. Different glass cutters have the ability to process glass of different thickness. You should take this point into account in advance so as not to be disappointed in your purchase later.

- Cutting head shape. This parameter affects not only the quality of the cut, but also the usability of the glass cutter.

- Working conditions... Depending on the working conditions of the glazier, the required type of glass cutter will differ. For example, under laboratory conditions, there should be no oil in the cutting area.

- Availability of additional accessories. Some models come standard with accessories along with the main instrument.It should be understood that the presence of additional elements can significantly increase the total cost of the glass cutter. Accordingly, you should consider in advance whether you need certain accessories.

- Manufacturing material. The stronger and more reliable the material for making the glass cutter, the longer this device will last.

- Manufacturer... Preference should be given to glass cutters from trusted manufacturers, which are widely known among users and are very popular and respected. This way you can be sure that the devices you purchase meet all international and national standards.

- Price... Today on the market you can find glass cutters of both budget and luxury categories. In this regard, you should focus primarily on your material capabilities. In general, you should choose tools from the middle price category, where the ratio of price and quality will be optimal.

- User reviews. Before purchasing a model you like, you should carefully study the reviews and comments of users about this device. Thus, you will be able to assess how much the characteristics declared by the manufacturer correspond to reality.

Taking into account all the above parameters, you can purchase a glass cutter that will meet all your needs and preferences, perform its functions efficiently and fully, and will also serve you for a long period.

Usage Tips

First of all, it is very important in the process of using a glass cutter to carefully observe all safety rules... Remember that improper use of the machine can result in serious injury. But before you start using the glass cutter, you need to carefully study the operating instructions, which are mandatory included in the standard package. In this document, all the principles of correct cutting are spelled out in detail.

However, there are a few simple rules.

- While the glass cutter is moving on the glass, the nature of the movement, pressure, speed must be constant. Stopping is prohibited, the line cannot be interrupted.

- The glass should be broken 2-3 seconds after the groove is made. Then it will not cool down yet, and the risk will not be dragged out by the vitreous tissue.

- There can be no second or third movement. Otherwise, there will be no flat edge, and this is a marriage.

- And, of course, only a quality tool should be used.

The comment was sent successfully.