All about diamond glass cutters

Cutting sheet glass with a glass cutter is a responsible and painstaking work that requires some preparation. First of all, you should choose a high-quality and reliable tool that fits comfortably in your hand and will allow even an inexperienced craftsman to cut the glass exactly, accurately, without errors.

Among the several types on the tool market, the most popular is the diamond glass cutter, which, in turn, is also available in two types. One or another type should be selected based on the tasks set.

Type overview

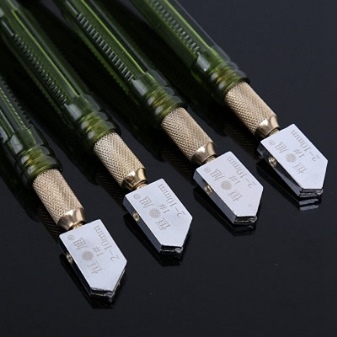

A diamond glass cutter is the simplest design, the weight of which does not exceed 80-100 g. It consists of a handle with a connecting tube, a hammer-shaped head and a rim, where a synthetic or natural diamond is placed. It is the diamond that is used to cut glass, acting as a cutting element. Models equipped with a synthetic cutting element are ideal for cutting glass with a thickness of up to 5-6 mm, and a tool with natural diamond (usually produced in Soviet times) cuts thicker blades - 7-10 mm and thicker. This factor undoubtedly affects the cost of the product. Based on design features (such as crystal sharpening), diamond glass cutters are divided into two types.

- Model with curvilinear cutters. The incisors are in line with the axis. This type of mechanical tool is more suitable for beginners.

- Model with a square edge, reminiscent of a pyramid. This is a professional type of glass cutter that is used exclusively by experienced glass cutters.

Diamond glass cutters marketed by domestic, Chinese and European manufacturers have an acceptable cost, which makes this tool affordable for every average buyer.

In addition to the affordable price, functionality and ease of use, diamond glass cutters are characterized by many features and benefits.

Peculiarities

A modern high-quality diamond glass cutter looks exactly like the models produced 30-40 years ago. Its length, together with the tip, can vary from 8 to 20 cm. According to the established standards, the length of the cutter of the professional model reaches 2.2 cm, the tool for beginner craftsmen is 1.6 cm. Several factors can be attributed to the main features of diamond glass cutters.

- The ability to perform an especially thin cut, which is important for the accuracy and clarity of the result.

- High performance. A diamond glass cutter with a natural cutting element can cut up to 15 km of glass, and a model with an artificial stone cuts up to 10 km of glass.

- Sensitivity and shock resistance. This is ensured by silver soldering of the tip onto a steel holder.

- Possibility to reinstall the tip. Thanks to the screw, the tip of the glass cutter with a square edge can be reset, that is, change the blunt cutting edge to a sharper one.

- The presence of a special protective anti-corrosion coating (for most high-quality models), which resists high humidity.

- Convenient handle shape. Typically, the edge of the handle has a teardrop shape that allows the instrument to slide smoothly into the hand. The handles are made of plastic or wood.

Besides, high-quality models have side slots, which are not decoration, but serve to break off the glass sheet along the cut lines. And also with the side with slots, it is convenient to tap the cut line if a large piece of glass is cut off.

Having studied all the technical characteristics, as well as the features of the tool, it is safe to say that a diamond glass cutter is better than an oil and roller cutter both for professional work and for use at home.

Selection Tips

Despite the fact that a glass cutter is a constructively simple device, choosing it is not as easy as it seems at first glance, especially for a beginner. To buy a quality tool that will last a long time, you need to pay attention to some nuances.

- Consider the scope of work. If the device is needed to replace window glass or an element of an interior item (shelf, glass insert), then it is enough to purchase a model with cutters that curvilinearly cutting the edge. For home or commercial use, a square cutter is a great help.

- To understand what kind of glass sheet you will have to work with - the thickness, hardness and texture of the glass must be taken into account.

- Pay attention to the ergonomics and shape of the tool handle. It is desirable that it be wooden. If the handle is plastic, then an anti-slip coating must be present.

It is also important how well the diamond is soldered into the holder. In addition, the shape of the cutting head and its size require attention. Small diamonds (0.02-0.1 carats) do an excellent job of cutting glass, the thickness of which does not exceed 5 mm, while larger ones (0.11-0.15 carats) are suitable for thick glasses. When buying a glass cutter, you need to remember that traces of corrosion, dents or the slightest burrs are unacceptable on the surface of any of its components.

And also the integrity of the device should be carefully monitored throughout the entire period of its operation.

How to use?

Using a new tool, especially for beginners, requires some knowledge of the preparatory work, and the very process of cutting glass. Useful information will not only save time, but also prevent glass damage during cutting.

Preparation

Before you start cutting glass, you need to prepare the place and surface where the process will take place. Preparation is accompanied by the implementation of some rules that should not be neglected.

- The surface on which the glass will lie should be as flat and smooth as possible. This is due to the fact that during cutting, a strong pressure is exerted on the glass itself, which can lead to the formation of unwanted cracks in places where there are irregularities on the surface.

- The surface should not be metal or wood. It is better to cover it with a soft cloth (felt, cotton), this will prevent slipping or scratching, and only then place the glass canvas.

- The glass must be clean and dry. Contamination can be removed with water or kerosene, wiping dry with a newspaper, paper towel, but not with a cloth, as lint can remain, which will interfere with the correct cut of the glass. If the glass is not new, then, in addition to cleaning, it should be degreased and dried.

Having prepared the surface and glass for cutting, it is imperative to prepare protective goggles to protect against small debris from entering the eye area, as well as buy gloves with a rubberized coating on the fingers. Sometimes before cutting (this applies to beginners), you should practice using the glass cutter correctly, for example, on unnecessary pieces of glass. The hand will quickly master and remember the mechanism of the instrument.

Another important point is checking the sharpening of the tool. This will also require an unnecessary piece of glass to be cut. If there is an unpleasant squeak during cutting, then the glass cutter needs to be sharpened.

Cutting process

By placing the glass on a suitable surface, the cutting process can be carried out.

- Marks are made on the glass using a marker. If the glass is patterned, then all markings are made on the clean side.

- The marks are connected in a line. For this, a ruler is used (preferably a wooden one, since plastic can slide on the glass).

- The edge of the diamond pebble is set at the beginning of the cutting line and the tool is cut along it with a continuous movement. It is better to cut from the edge of the glass towards you, while gradually relieving the pressure on the glass cutter. You need to hold the tool in your hand just like a pencil. With the right process, a crunch-like sound is always heard. A correct cut is a subtle white thin line. You can only run the glass cutter along a given line once.

- The glass is broken. Along the formed cut line (on the back side of the glass), it is necessary to easily tap with a hammer (to deepen the cracks), and then the glass is slid to the edge of the table and breaks off. This should be done with gloves.

Most of the glass sheet can be broken off by hand, and a small section can be broken off with pliers.

After the glass has been cut and broken off, it is necessary to give the edge of the glass sheet smoothness. If the glass is cut to fit into a window, door, or portrait frame, sanding the edges is not necessary. If this is glass for shelves, an aquarium, a coffee table, a table top, then edge processing is necessary. This is done in several ways.

- A sharpening attachment is installed on a regular electric drill, and the edges are slowly processed.

- Sandpaper is stretched over a wooden block. It is optimal to use two types of paper - first coarse, and then fine.

- By means of a grindstone.

Whichever method is chosen, the main thing is not to rush so that cracks do not form on the glass due to slipping, since this material is very fragile.

For information on how to properly cut with a diamond glass cutter, see the next video.

The comment was sent successfully.